Single protrusion permanent magnetic motor scheme

A technology of permanent magnet motor and salient pole, which is applied in the direction of electrical components, electromechanical devices, magnetic circuit rotating parts, etc., can solve problems such as unsatisfactory manufacturability, achieve low-speed torque ripple reduction, eliminate magnetic flux leakage, and unique structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

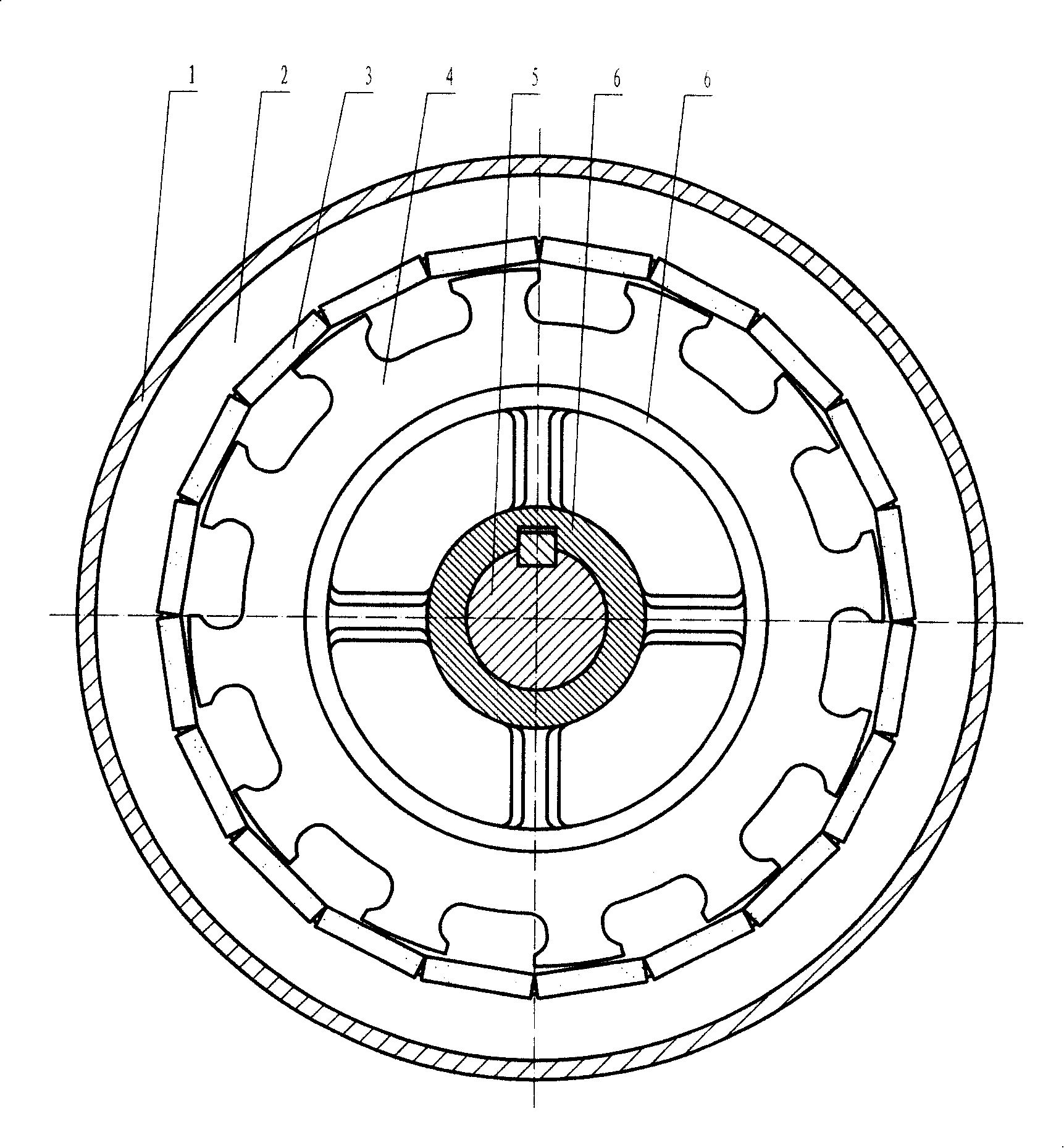

[0029] Embodiment 1: Single salient pole three-phase four-pole external rotor permanent magnet motor

[0030] refer to figure 1 In the figure, the inner stator core (2) is sleeved on the stator support (6), and there is a fixed shaft (5) in the middle of the stator support (6); the rotor core (4) is installed on the rotatable casing (1), and the iron The inside of the core is pasted with a permanent magnet (3). figure 1 The motor stator has twelve magnetic poles, which are divided into three phases, and each phase has four magnetic poles; the rotor has twenty permanent magnets, and every two adjacent permanent magnets are arranged in opposite polarities, and the magnetization direction is perpendicular to the surface of the air gap.

[0031] Compared with the conventional permanent magnet motor, the motor shown is only half of the stator poles. If the conventional motor principle is used, the motor should be called a 20-pole motor, but this is a reluctance motor, which is a t...

Embodiment 2

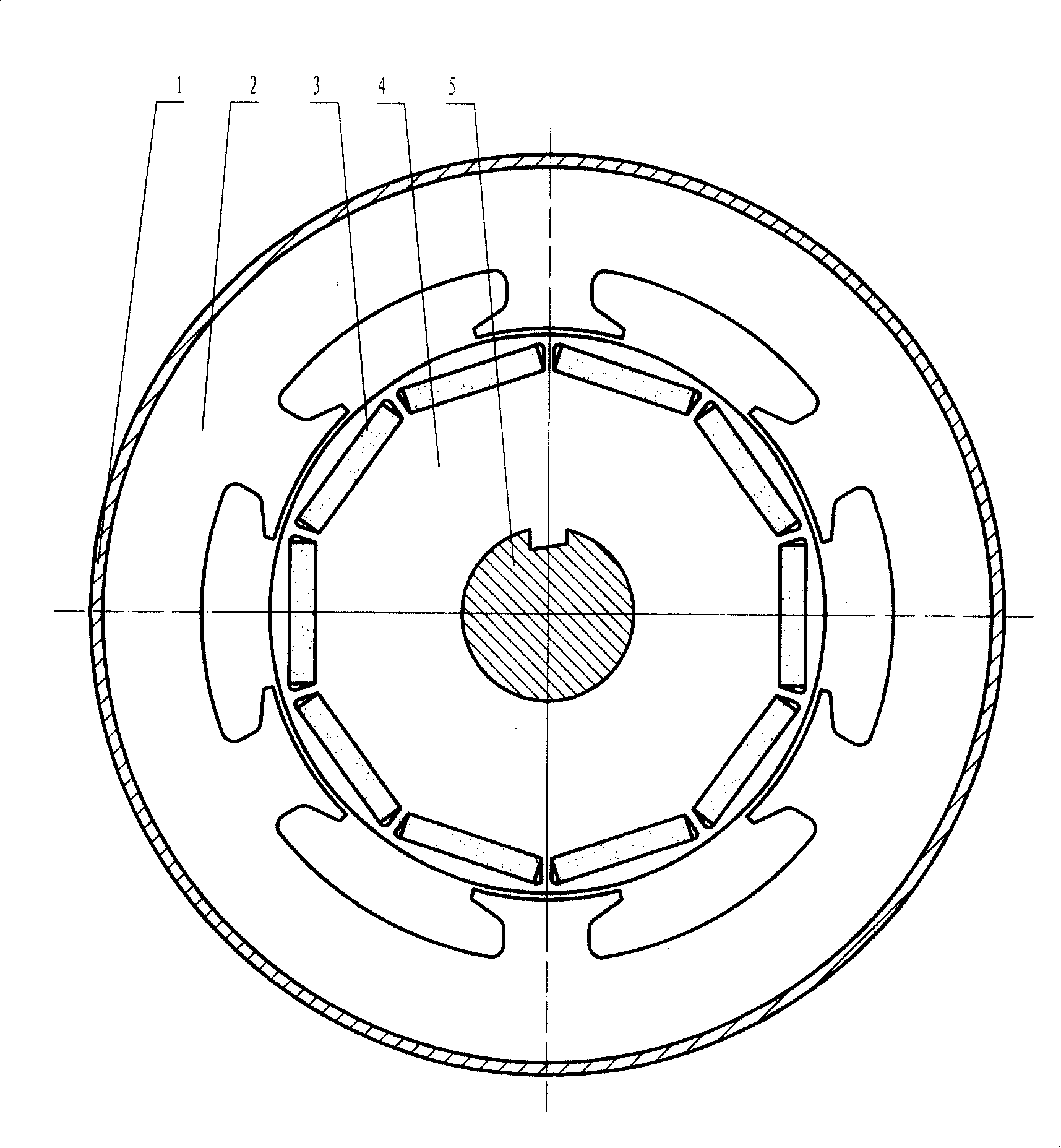

[0033] Embodiment 2: Single-salient pole three-phase two-pole inner rotor permanent magnet motor

[0034] refer to figure 2 , which is a schematic diagram of a single-salient-pole three-phase two-pole inner-rotor permanent magnet motor, and the leading marks in the figure are the same as those in Embodiment 1. In the figure, the outer stator core (2) is contained in the casing (1), the rotor core (4) is contained on the rotating shaft (5), and the rotor core is inlaid with a permanent magnet (3). figure 2 The stator of the motor has six magnetic poles, which are divided into three phases, and each phase has two magnetic poles; the rotor has ten permanent magnets, and every two adjacent permanent magnets are arranged in opposite polarities, and the magnetization direction is perpendicular to the surface of the air gap.

[0035] Compared with Example 1, this example is only different in the difference between the inner and outer rotors and the way the permanent magnets are fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com