Device for transporting fuel

A technology for fuel and storage container, applied in the field of devices for conveying fuel, can solve the problem of high cost of wire hoops, and achieve the effects of easy installation and replacement, reduced manufacturing cost and installation cost, and reliable preloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

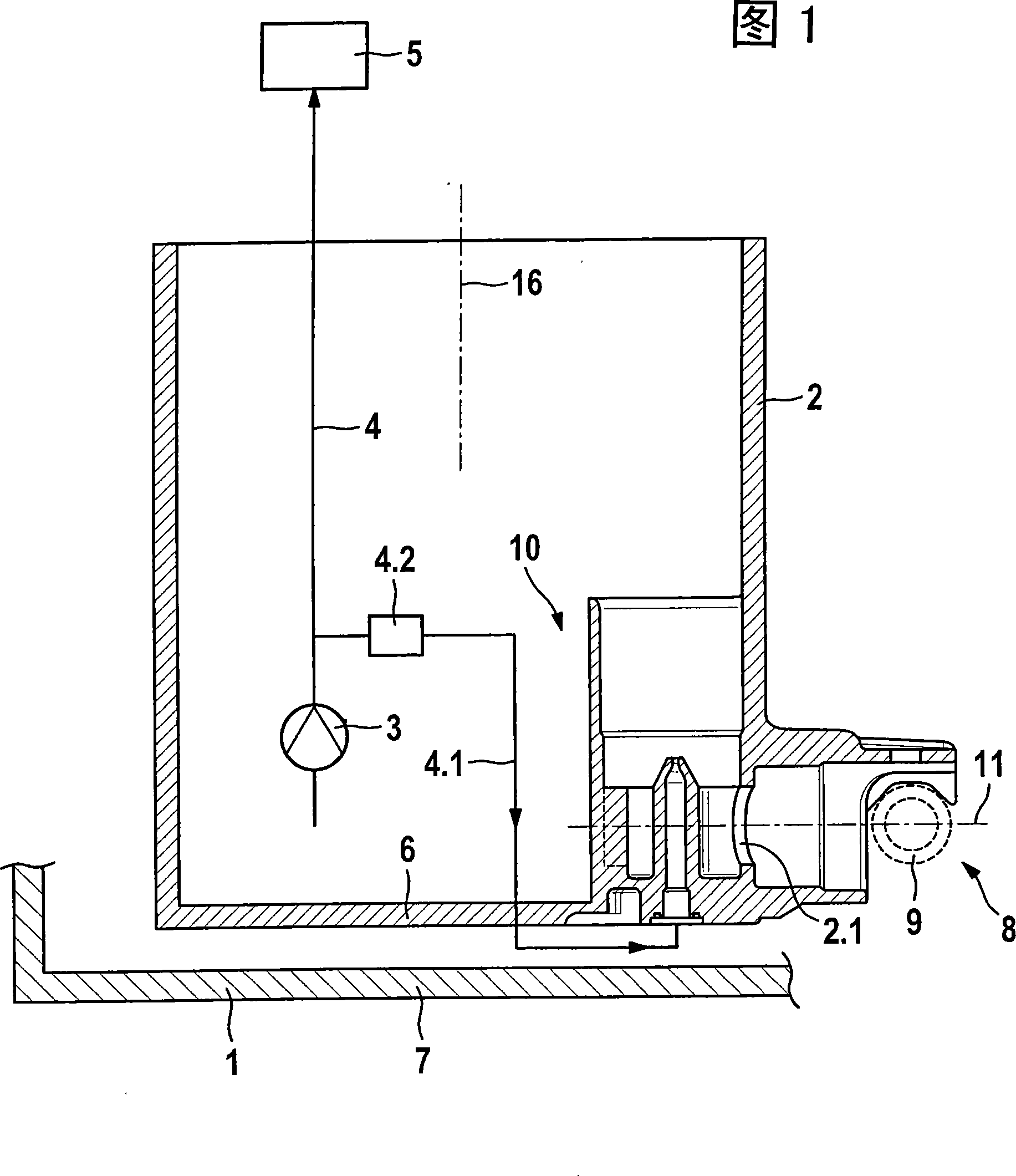

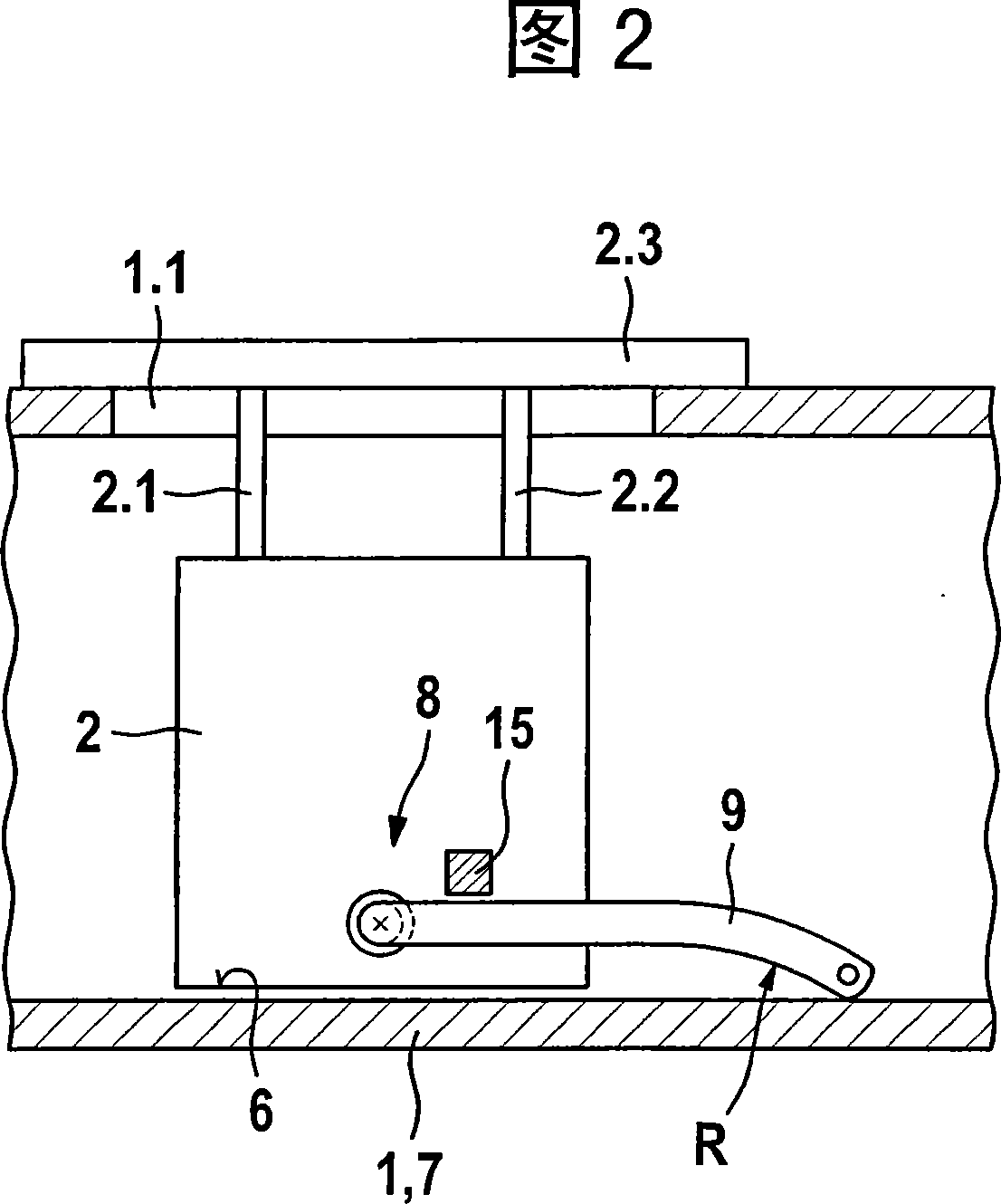

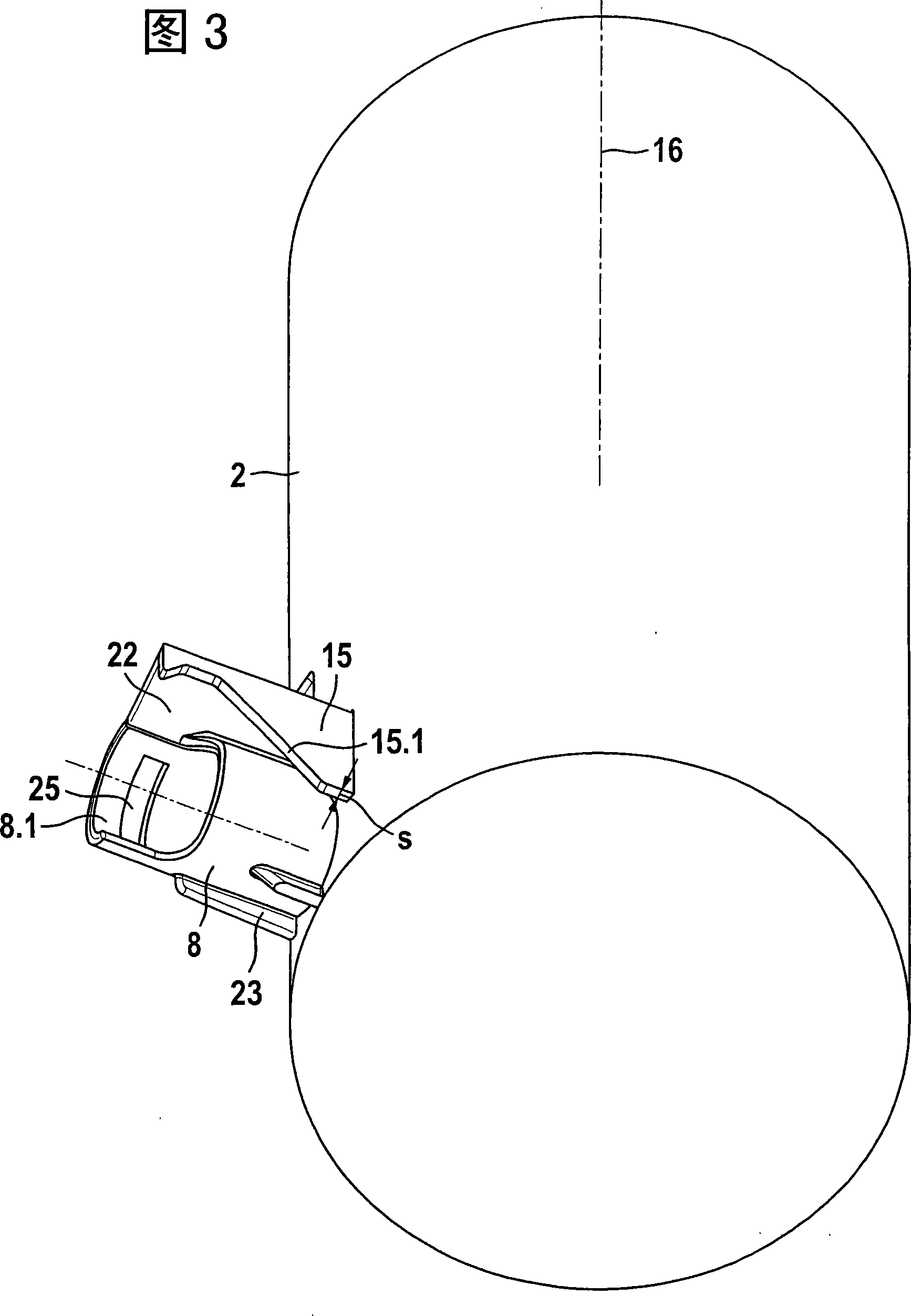

[0018] Figure 1 shows a simplified view in section of a device with a storage container according to the invention.

[0019] The device is housed in a fuel-filled storage tank 1 . It has a storage container 2 and a conveyor unit 3 , which is accommodated, for example, in the storage container 2 and draws fuel from the storage container. The feed unit 3 feeds the fuel under increased pressure via the pressure line 4 to the internal combustion engine 5 . Specifically, however, the conveyor assembly 3 can also be arranged outside the storage container 2 or storage container 1 . The storage container 2 is placed on the bottom 7 of the storage container 1 and serves to keep sufficient fuel around the conveyor assembly 3, so that even when the liquid level in the storage container 1 is low and when the vehicle accelerates, brakes, curves and And / or when driving on slopes, the conveyor unit can also suck fuel. The storage container 2 , which is, for example, pot-shaped, has a bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com