Fire proofing rolling door

A rolling door and hoist technology, applied in fire doors, windows/doors, door/window protection devices, etc., can solve problems such as casualties, obstacles to escape passages, and inability to open rolling doors, and achieves delay in heat conduction time, Improve blade quality and improve the effect of heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

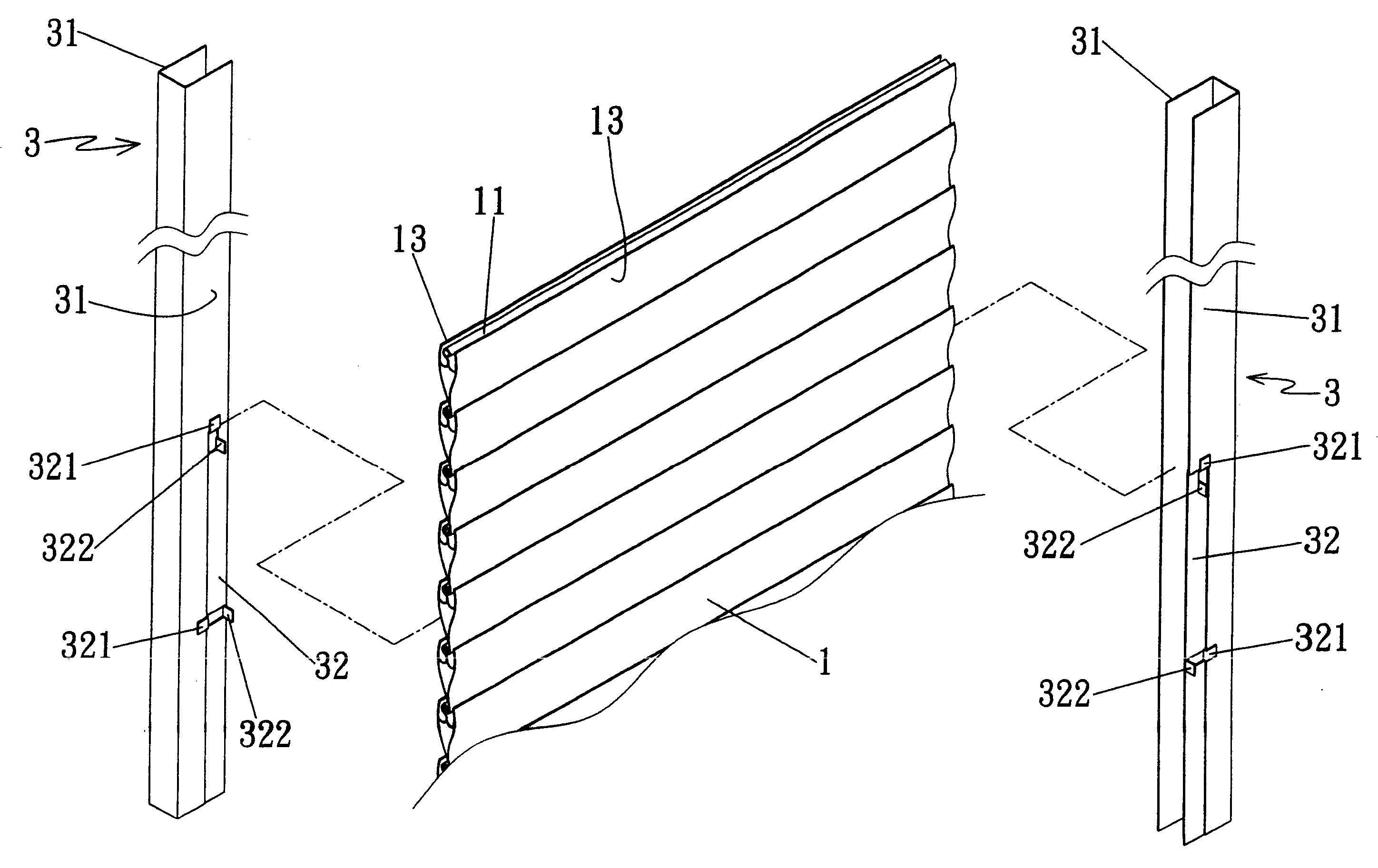

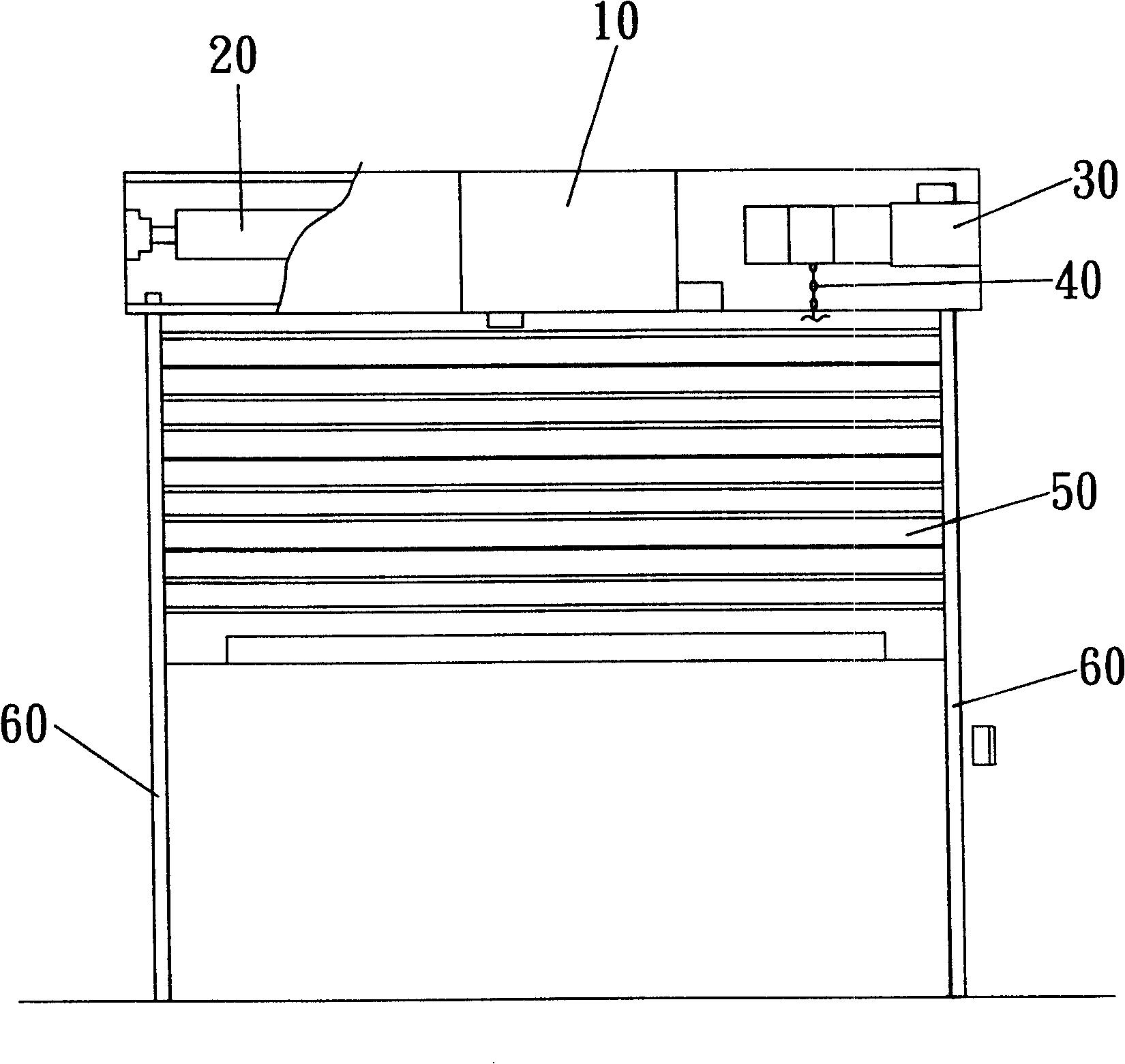

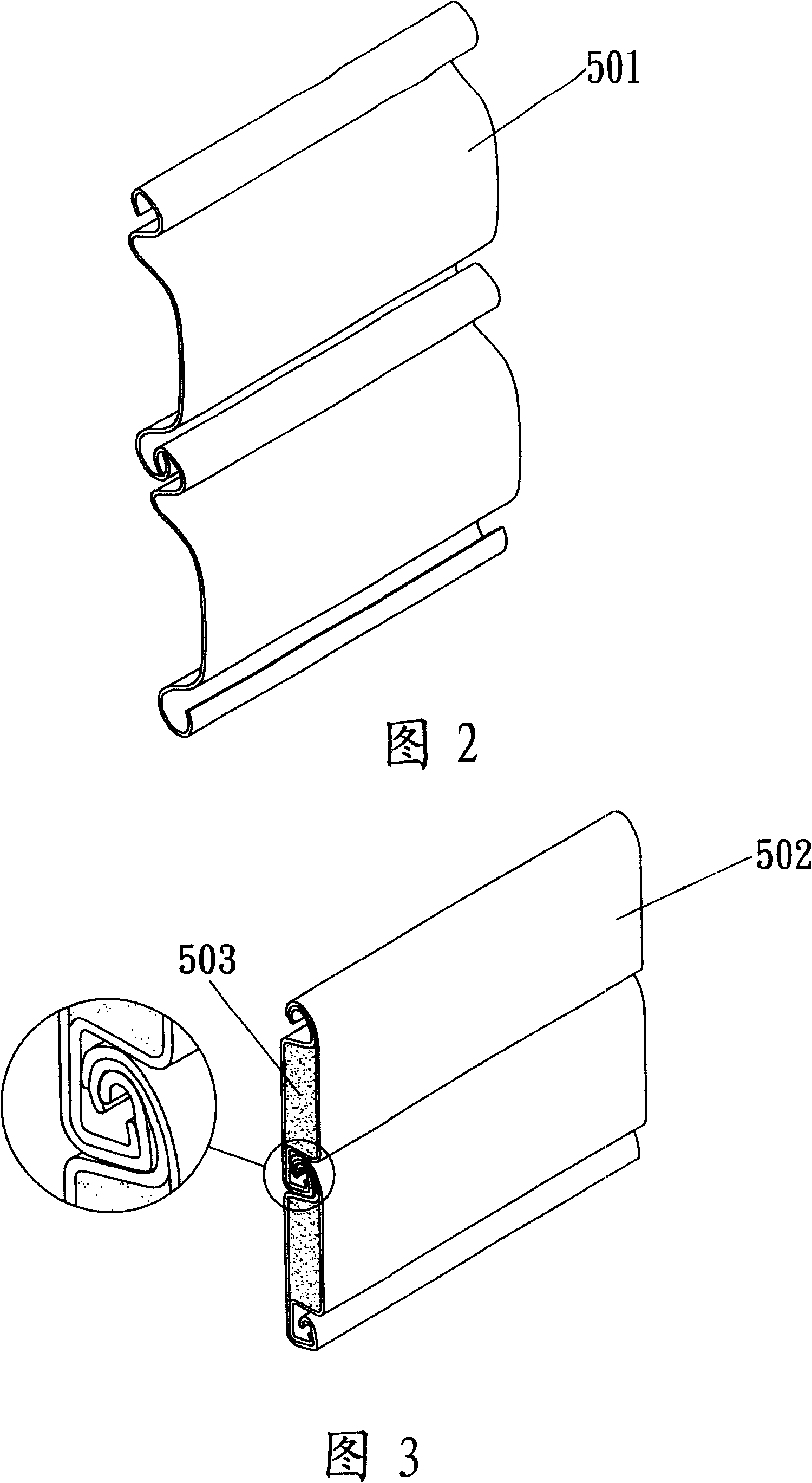

[0037] Please refer to Fig. 5 first, the present invention provides a metal rolling door and its guide rail as shown in the figure, and the metal rolling door is connected by a large number of blades 1 as shown in Fig. 6A and Fig. 6B Composition, wherein, the blade 1 is made of a metal pipe body through multiple rolling integrally formed (because the rolling process is not the focus of the present invention, so it will not be described and shown in detail), each blade 1 The upper and lower hook bodies 11, 12 of the double-layer structure are all formed, and the front and rear sides of the upper hook body 11 are respectively integrally extended with a suitable height retaining wall 13 with a double-layer structure. The pair of retaining walls 13 The surface and the upper hook body 12 are all coated with fireproof paint 14 (the described fireproof paint is a flame-resistant grade fireproof paint that has passed the national standard inspection, and the blade 1 structure as shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com