Electric heating method for melting snow and ice on cement concrete bridge floor

A technology of cement concrete and electrothermal method, which is applied in the direction of bridges, bridge parts, pavement details, etc., can solve the problems of conductive concrete resistance increase, large manpower, material resources and equipment, and affect conductive performance, so as to achieve low construction operation and maintenance costs, Maintain smooth traffic and high heat conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

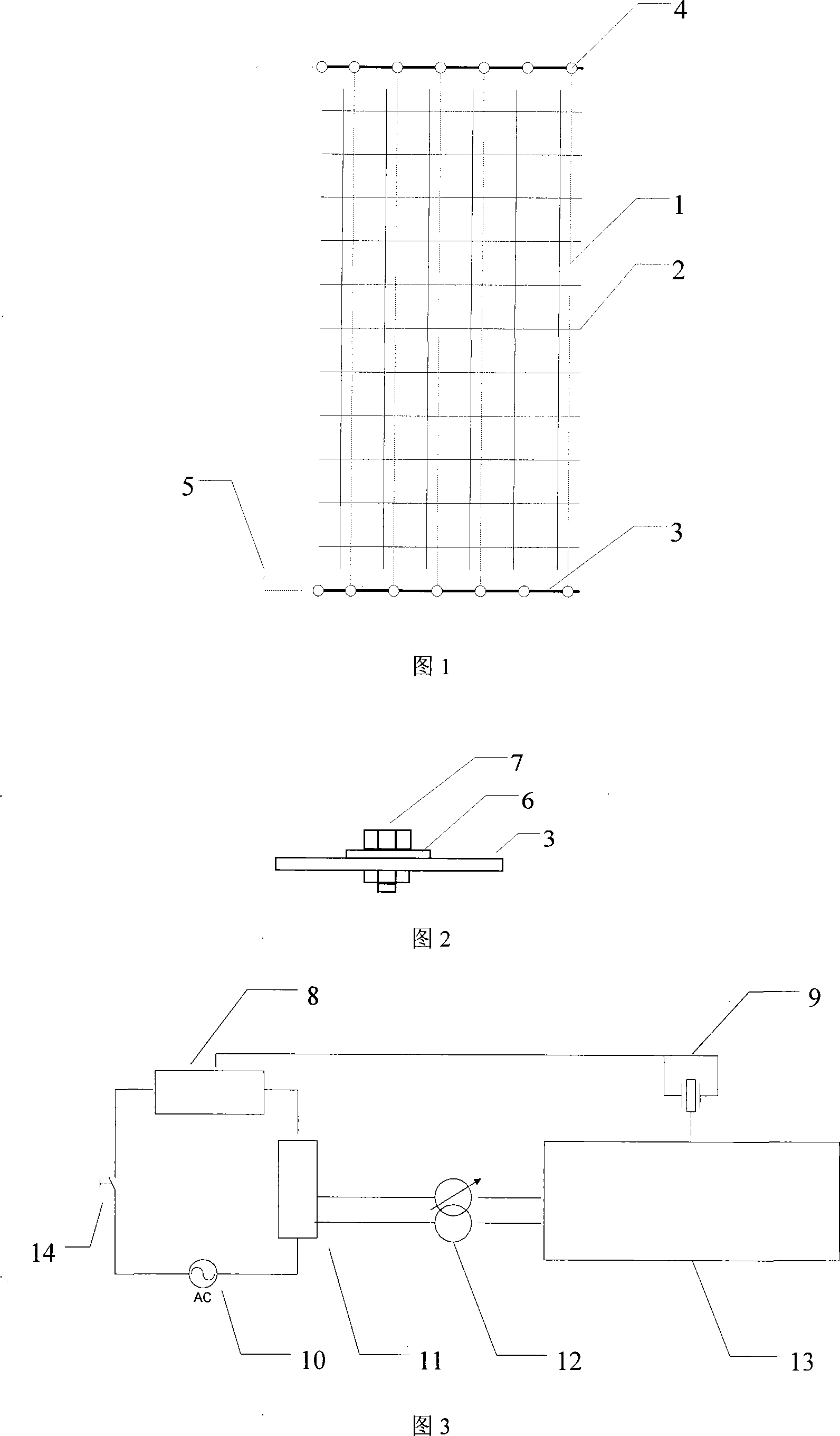

[0011] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

[0012] In Figure 1 and Figure 2, the carbon fiber heating wire 1 is unidirectionally wound on the bundled or welded steel mesh (or steel wire mesh) 2, and the steel plate 3 used as the electrode is drilled with a diameter of 6mm in advance, and the screw type is selected as M6, and the metal gasket 6 is set on the screw 7, and then the outer layer of the carbon fiber heating wire is removed, and the exposed carbon fiber wire is wound on the screw 7, and the screw passes through the steel plate 3 and is tightened with a nut, and the heating wire is squeezed between the metal gasket 6 and the steel plate between 3. Note: The fixed joints should try to prevent the exposed carbon fiber wires from being exposed to the metal gasket. Part of the carbon fiber heating wire sheath should be squeezed into the steel plate and metal gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com