Fermentation method for preparing L-amino acid

An amino acid and fermentation medium technology, applied in the field of bioengineering, can solve the problem of high production cost, and achieve the effect of reducing production cost and improving acid production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: seed culture medium (g / dl): glucose 3, corn steep liquor 3, bean concentration 2, K 2 HPO 4 0.15, MgSO 4 ·7H 2 O 0.04, urea 0.2, adjust the pH to 7.0-7.2, and heat at 115°C for 15 minutes to sterilize.

[0031] Brevibacterium flavum ATCC 14067 was inoculated in a 5L seed tank, and cultured with shaking at 32°C for 9 hours.

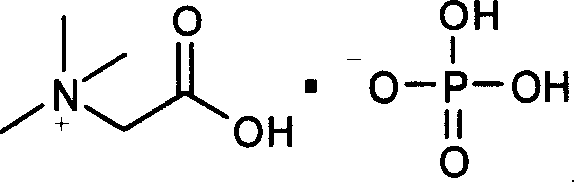

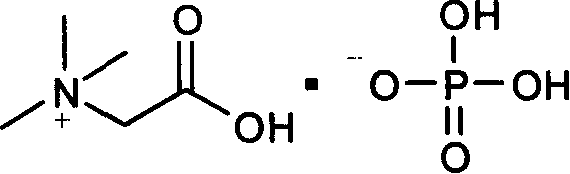

[0032]In addition, the glutamic acid fermentation medium (g / dl) is: glucose 14, molasses 0.1, Na 2 HPO 4 0~0.1, KCl 0.12, MgSO 4 ·7H 2 O 0.08, FeSO 4 4H 2 O 0.0002, MnSO 4 0.0002, Vitamin B 1 20 mu g / l. 0.05-0.3 g / dl of betaine phosphate was added to the medium respectively, and the pH was adjusted to 7.0. Put 3L of medium into a 5L fermenter, and heat at 115°C for 15 minutes to sterilize.

[0033] Insert 300 ml of the seeds obtained by the above-mentioned culture into each fermenter, and culture in aeration at a temperature of 34°C. During the cultivation process, ammonia water was used to adjust the pH of the medium to ...

Embodiment 2

[0037] Embodiment 2: seed culture medium (g / dl): glucose 3, corn steep liquor 3, bean concentration 2, K 2 HPO 4 0.15, MgSO 4 ·7H 2 O 0.04, urea 0.2, adjust the pH to 7.0-7.2, and heat at 115°C for 15 minutes to sterilize.

[0038] Brevibacterium flavum ATCC 14067 was inoculated in a 5L seed tank, and cultured with shaking at 32°C for 9 hours.

[0039] In addition, the L-glutamic acid fermentation medium (g / dl) is: glucose 14, molasses 0.1, Na 2 HPO 4 0~0.1, KCl 0.10, MgSO 4 ·7H 2 O 0.08, FeSO 4 4H 2 O 0.0002, MnSO 4 0.0002, Vitamin B 1 20mu g / l, adjust the pH to 7.0. Put 3L of medium into a 5L fermenter, and heat at 115°C for 15 minutes to sterilize.

[0040] Insert 300 ml of the seeds obtained by the above-mentioned culture into each fermenter, and culture in aeration at a temperature of 34°C. During the cultivation process, ammonia water was used to adjust the pH of the medium to maintain it at 7.2, and at the same time, 70% glucose aqueous solution was continu...

Embodiment 3

[0043] Embodiment 3: seed medium (g / dl): glucose 2.5, (NH4) 2 SO 4 0.5, KH 2 PO 4 0.1, MgSO 4 ·7H 2 O 0.05, corn steep liquor 3.5-4.0, CaCO 3 1.0, pH adjusted to 7.0-7.2, sterilized under 0.1Mpa pressure for 20 minutes.

[0044] Brevibacterium flavum ATCC 14067 was inoculated in a 5L seed tank, and cultured with shaking at 31°C for 12 hours.

[0045] The fermentation medium (g / dl) of L-lysine is: glucose 18, (NH4) 2 SO 4 50, KH 2 PO 4 1, KCl 0.12, MgSO 4 ·7H 2 O 0.5, corn steep liquor 0.5-1.5, L-threonine 0.4, CaCO3 4.0, respectively add 0.05-0.3g / dl betaine phosphate to the medium, and adjust the pH to 7.0-7.2. Put 3.6L medium into a 7L fermenter, and sterilize it under 0.07Mpa pressure for 8 minutes.

[0046] Insert 360 ml of the seeds obtained by the above-mentioned culture into each fermenter, and culture in aeration at a temperature of 30°C. During the cultivation process, ammonia water was used to adjust the pH of the medium to maintain it at 6.7, and at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com