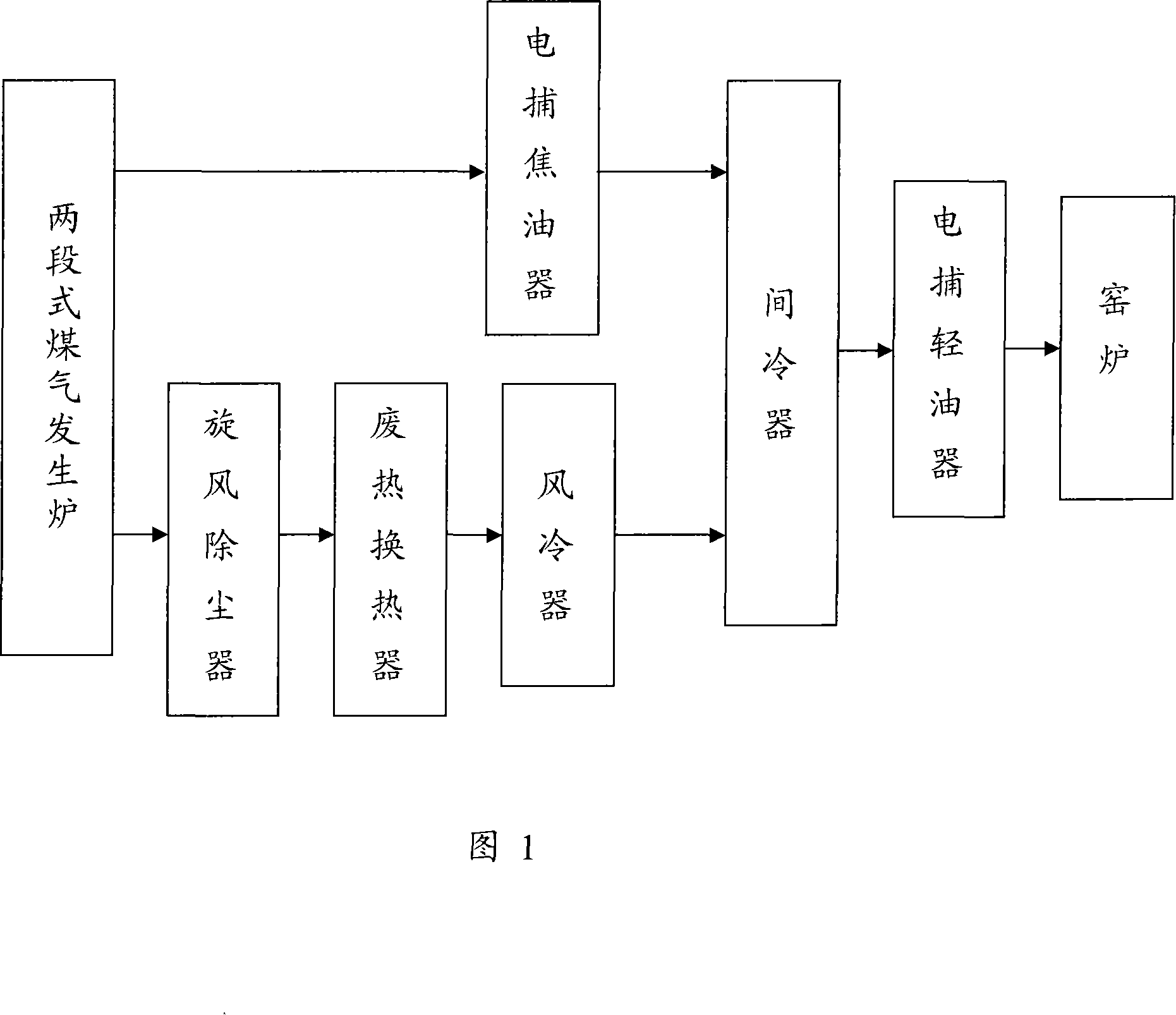

Coal gasification cooling technique and device

A coal gasification and cooling device technology, applied in combustible gas purification, combustible gas purification/transformation, petroleum industry, etc., can solve the problems of dust, phenolic water difficult to handle, large energy consumption, serious environmental pollution, etc., to prevent gas Deflagration hazard, low operating cost, and the effect of purifying living space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

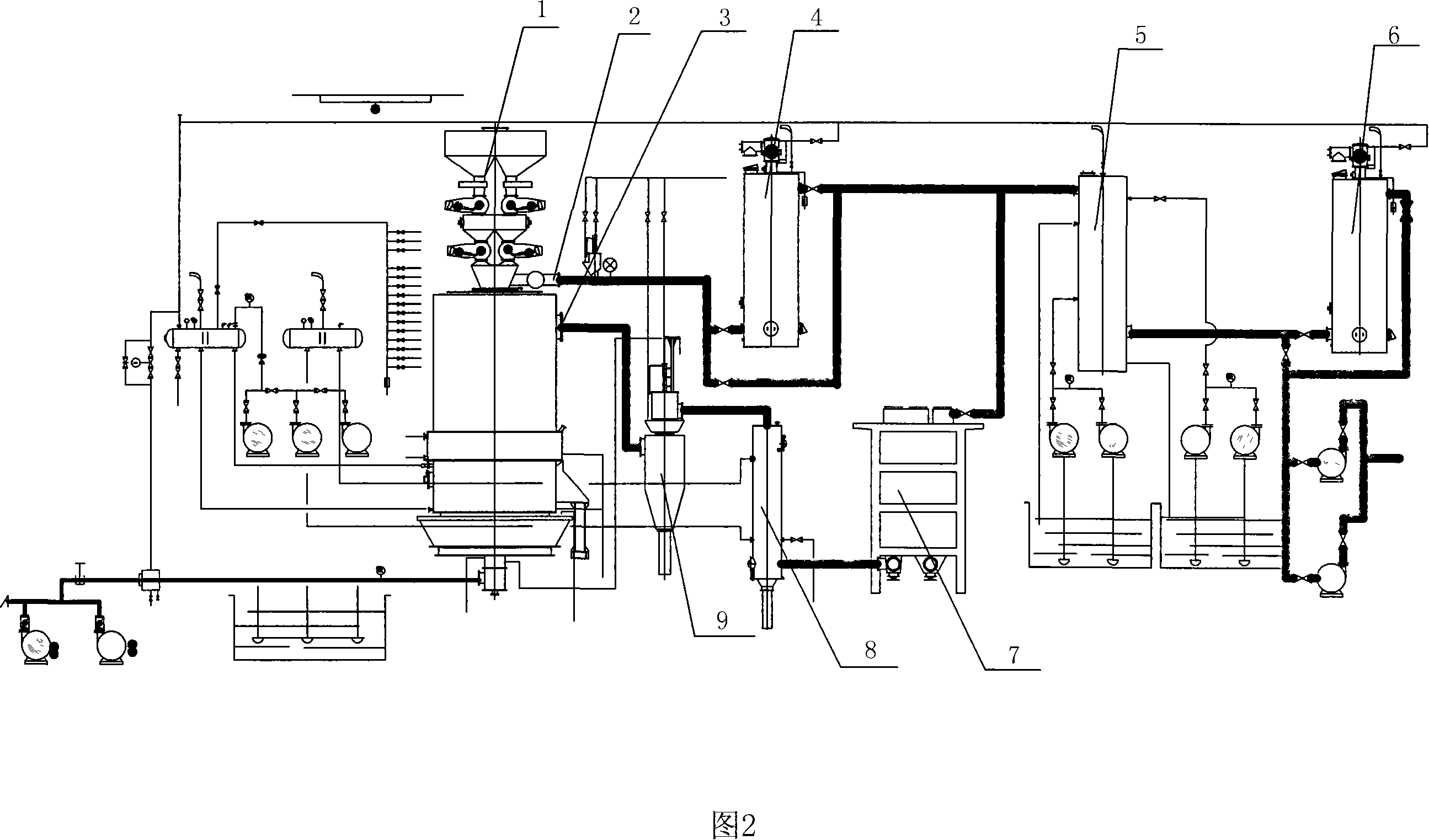

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] The two-stage coal gasifier gas production belongs to the air blast continuous gas production method. The water jacket of the furnace body and the waste heat exchanger self-produced low-pressure steam and the saturated gas mixed with the blast air are used as the gasification agent, and the saturation temperature is generally controlled. Between 55°C and 65°C. Through the dry check valve, the air duct at the bottom of the gas furnace passes through the grate and enters the gasifier. In the gasification section, it reacts with the hot semi-coke formed by the reversely added raw coal to generate hot gas, of which nearly 75 % of the hot gas is exported through the central steel pipe and the channel in the annular furnace wall to form the bottom gas, and the remaining 25% of the hot gas directly heats, dries, and drys the bituminous coal in the retort section, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com