Coil body for an electric coil and method for producing an electronic element provided with said coil body

A technology of electronic components and bobbins, applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor parts, coils, etc., can solve problems such as troublesome and extra costs, and achieve trouble-free manufacturing process and cheap manufacturing , reliable and safe insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

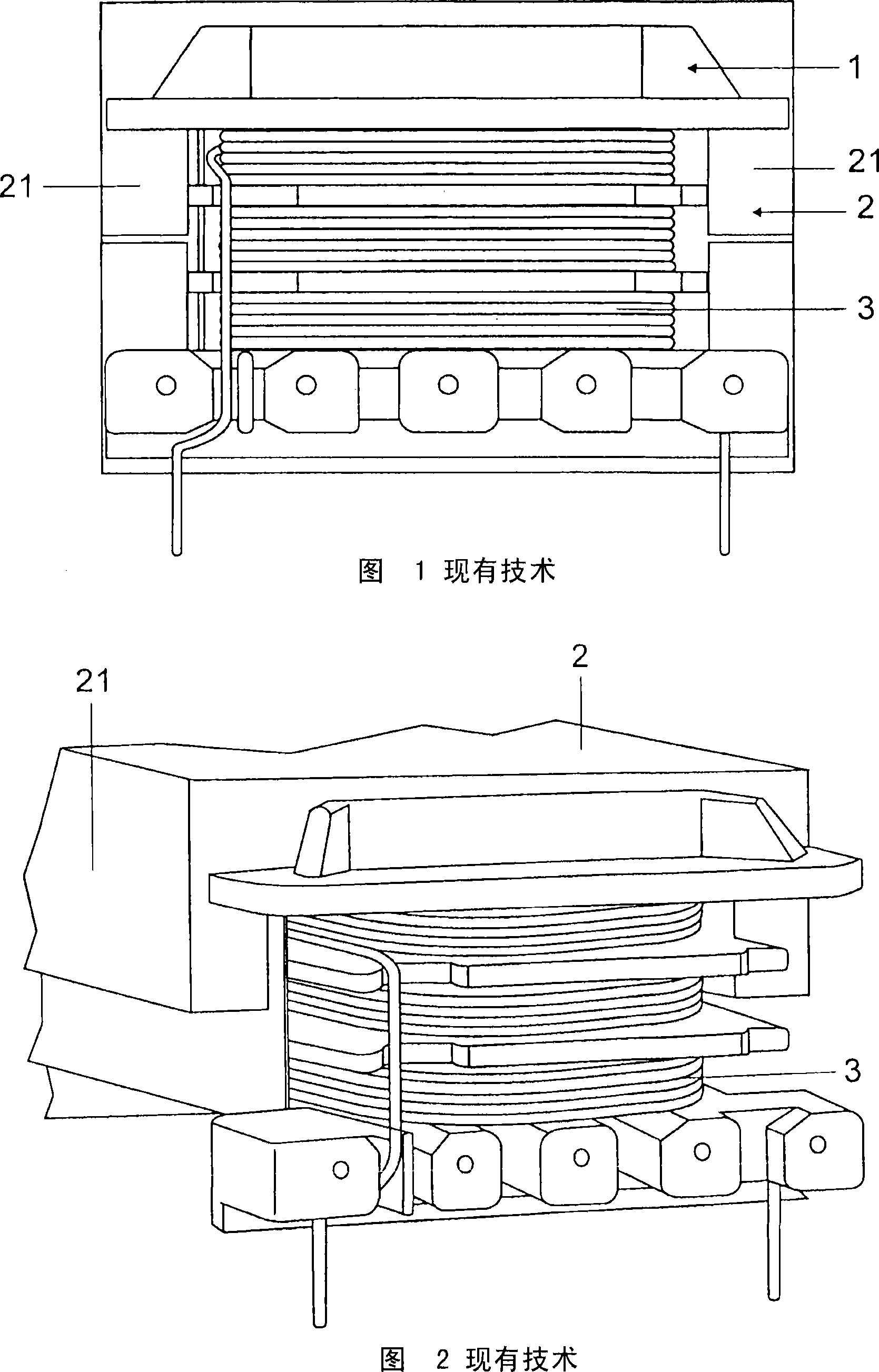

[0025] In the figures, identical or functionally identical elements are provided with the same reference signs.

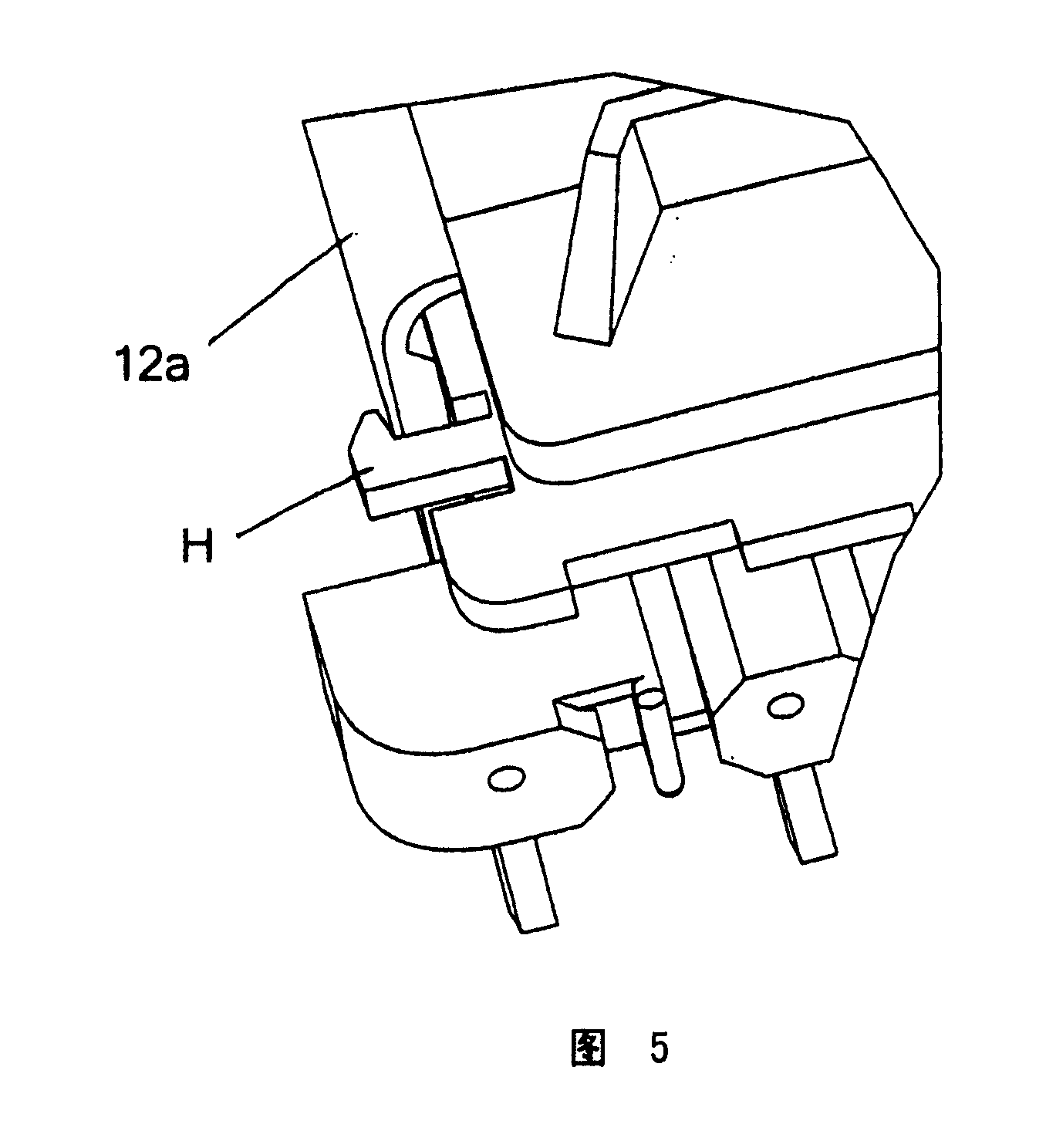

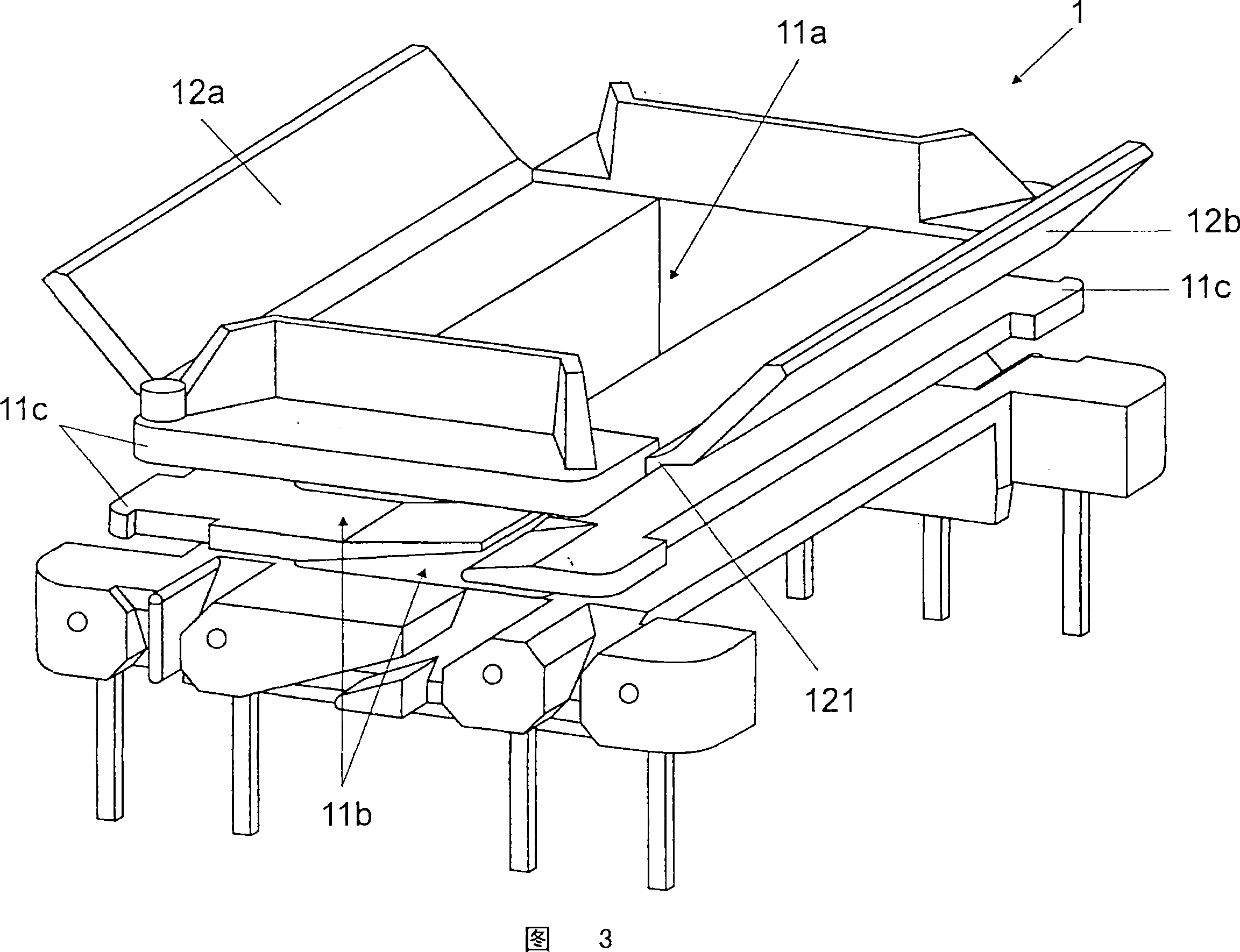

[0026] The coil former 1 according to the invention is shown in the schematic diagram of FIG. 3 . Said coil former 1, in its essential element for the invention, comprises an intermediate region with a hollow interior 11a. A partial area of the coil core 2 (not shown) can be positioned in this hollow lumen 11a. The middle region has an outer side 11b on which the winding 3 (not shown) can be wound completely around the middle region of the coil former 1 . As can be seen, the stationary positioning element 11c rests on this outer side surface 11b. As a result, the position of the winding 3 arranged on the outer side 11b can be kept stable. The movable flaps 12a and 12b are mounted on the coil former 1 as the main elements of the coil former 1 according to the invention. As can be seen, in the embodiment according to FIG. 3 the two flaps 12a and 12b are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com