Automatic winding equipment and winding method for motor coil

An automatic winding and coil technology, applied in the direction of electric components, manufacturing motor generators, electrical components, etc., can solve the problems of error-prone, low work efficiency, boring and repetitive work, etc., to avoid demoulding, improve production efficiency, and wind Wire process for quick and easy results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0036] Example.

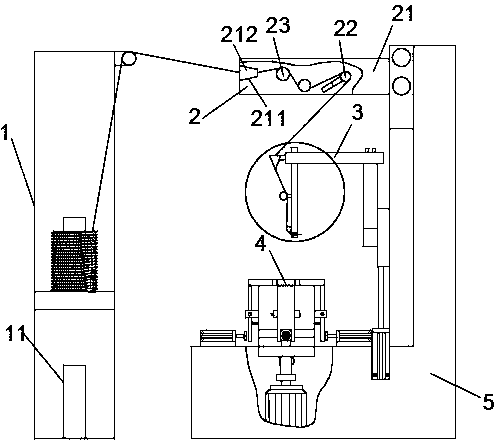

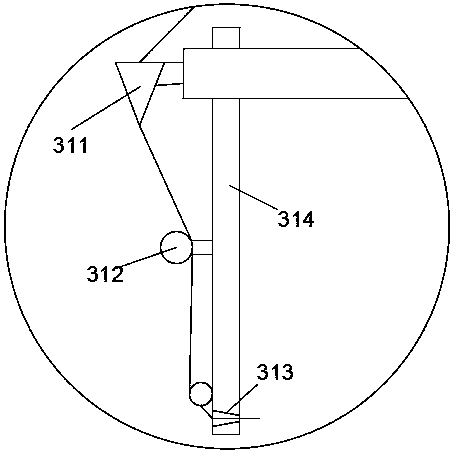

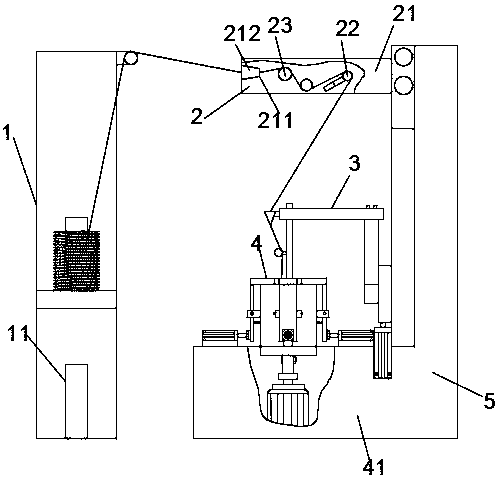

[0037] see Figure 1 to Figure 8 , the motor coil automatic winding equipment in the present embodiment comprises a coil frame 1, a wire inlet mechanism 2, a frame 5, a pinch-off mechanism 6 and a winding mechanism; the coil frame 1 is provided with several fixing piles 11; the pinch-off mechanism 6 is provided with the wire cutter of cutting copper wire. The winding mechanism includes a winding device 3 for clamping and winding copper wires and a winding die fixing device 4 for clamping and rotating the winding die; the action of the winding device 3 cooperates with the action of the winding die fixing device 4 .

[0038] The line feed mechanism 2 in the present embodiment comprises pulley fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com