Valve with diameter-reduced joint part, joint for diameter reduction, and pipe system using these valve and joint

A technology for joints and diameter reduction, which is applied in the direction of pipes/pipe joints/fittings, connections with fluid cut-off devices, valve lifts, etc., which can solve problems such as space constraints for piping installation, complex piping structures, and lack of flexibility. , achieve the effect of reducing the burden on the operator, improving the workability and reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

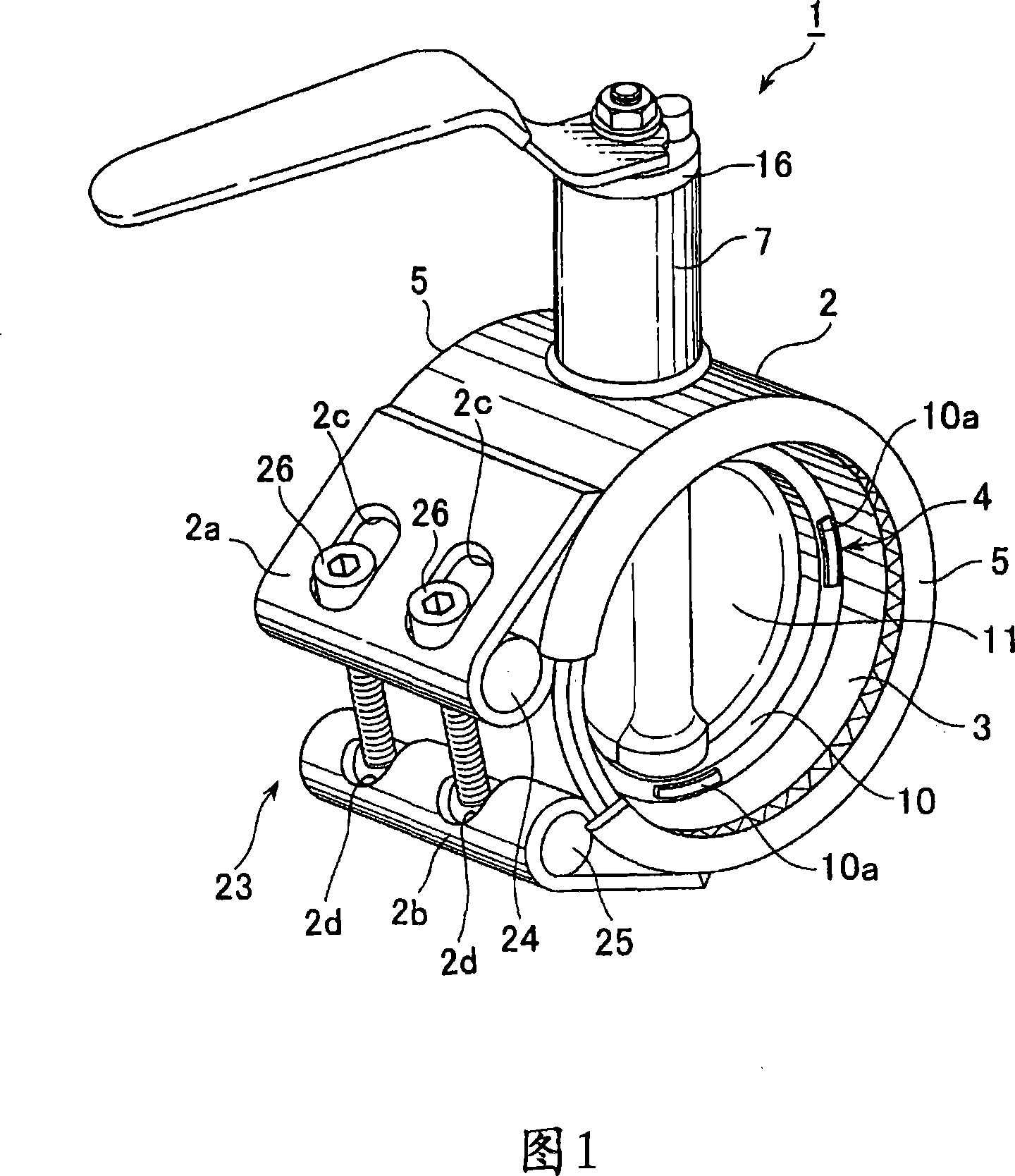

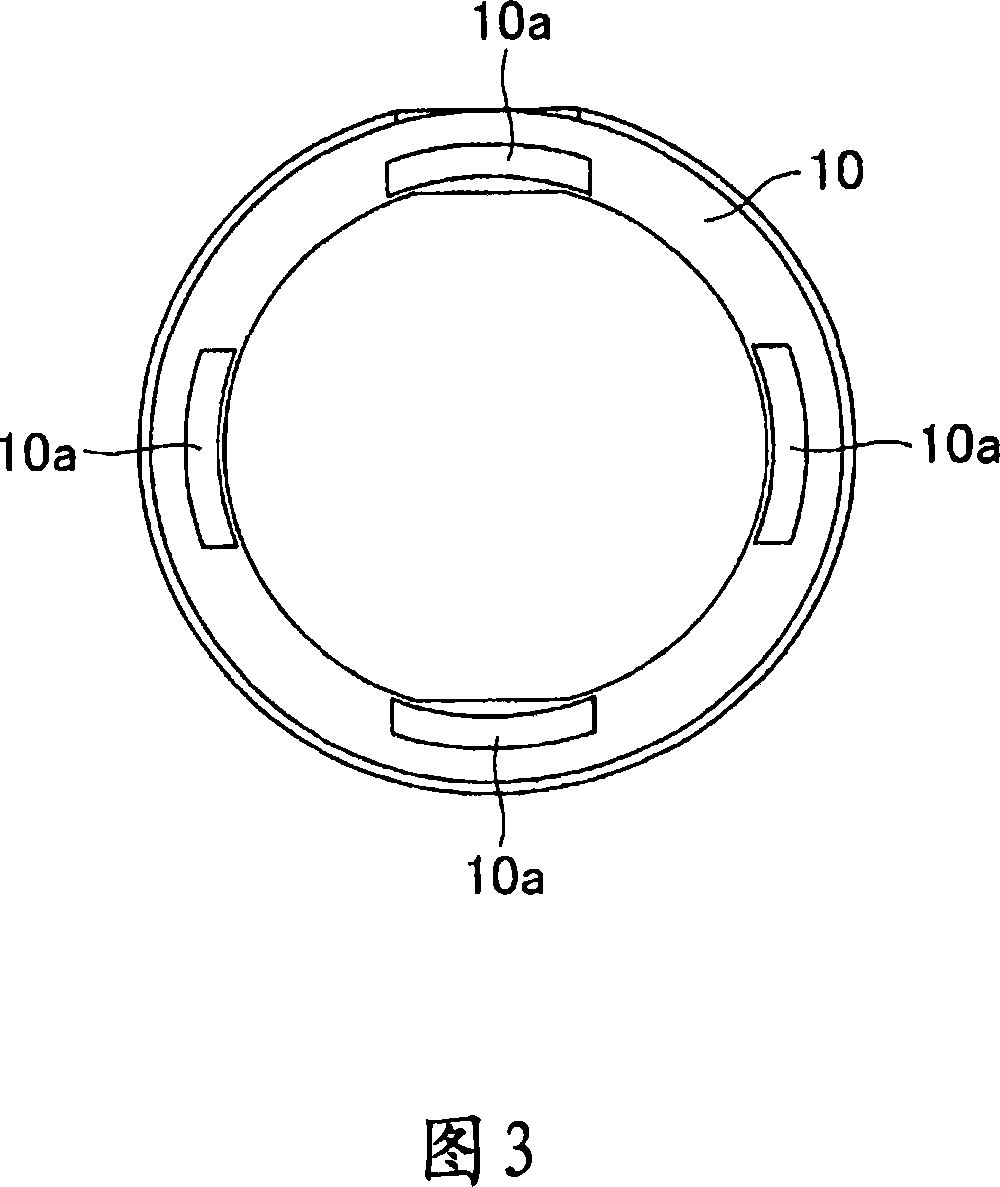

[0116] Hereinafter, embodiments of a valve having a reduced-diameter joint portion in the present invention will be described in detail with reference to the drawings. First, a first embodiment in which the valve of the present invention is used as a butterfly valve will be described. FIG. 1 is a perspective view showing a first embodiment. Fig. 2 is a cross-sectional view showing the first embodiment. Fig. 3 is a side view of a cylinder in the first embodiment. The valve body 1 of the present invention accommodates a sealing sleeve 3 formed by rubber or the like in a housing 2 that can be reduced in diameter, and the housing 2 houses a valve mechanism 4 with a valve core (disc of a butterfly valve), and the housing 2 In addition, the housing 2 is reduced in diameter, and the joint end portion of the joint pipe P (hereinafter referred to as pipe P) is hermetically joined by the sealing sleeve 3 .

[0117] As shown in Fig. 1 and Fig. 2, the housing 2 is made of metal materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com