Spun-laced compound nonwoven material containing line elastomer, preparation method and equipment thereof

A technology of non-woven materials and elastomer materials, which is applied in the field of non-woven materials, can solve the problems that the materials cannot meet the elastic requirements and the manufacturing process is complicated, and achieve good contact comfort and wearing safety, soft hand feel, and reduce energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

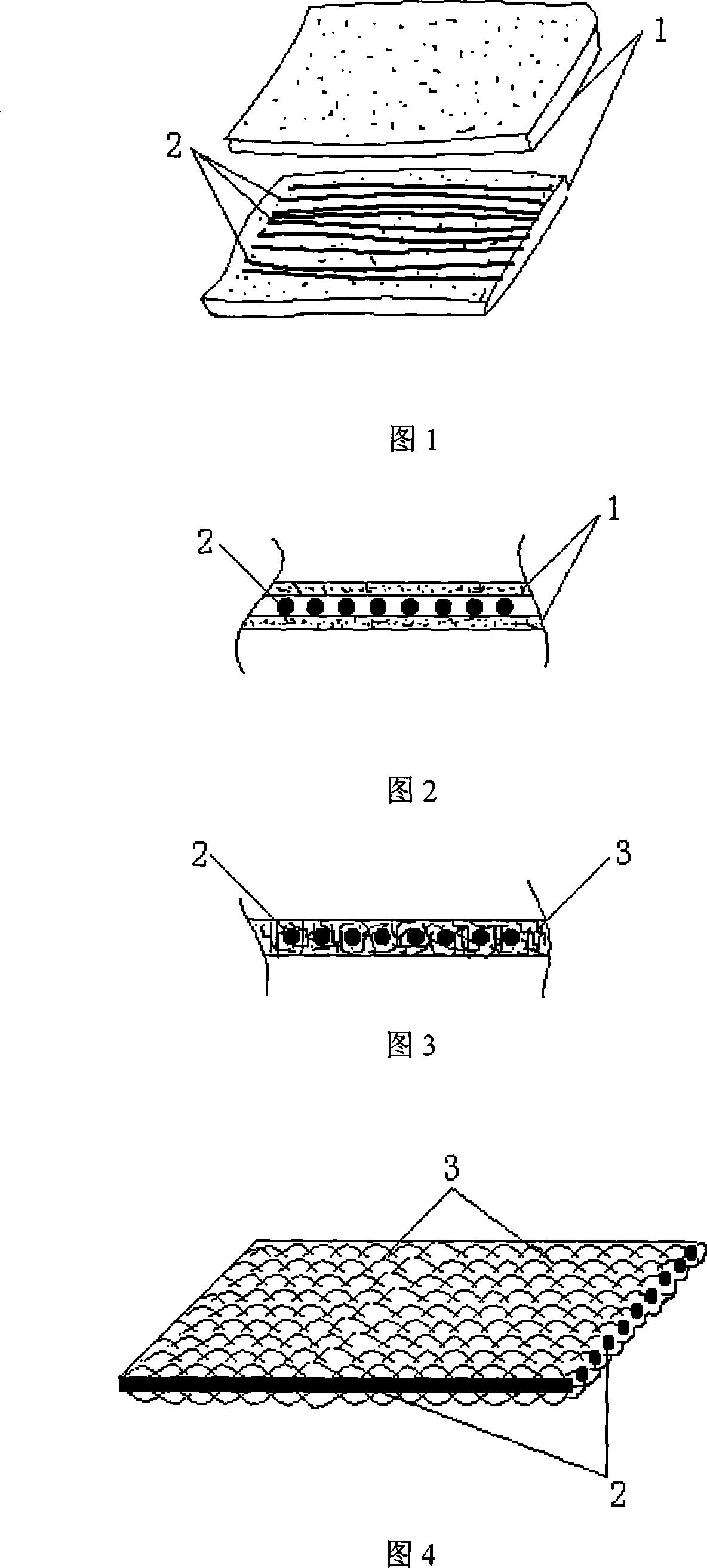

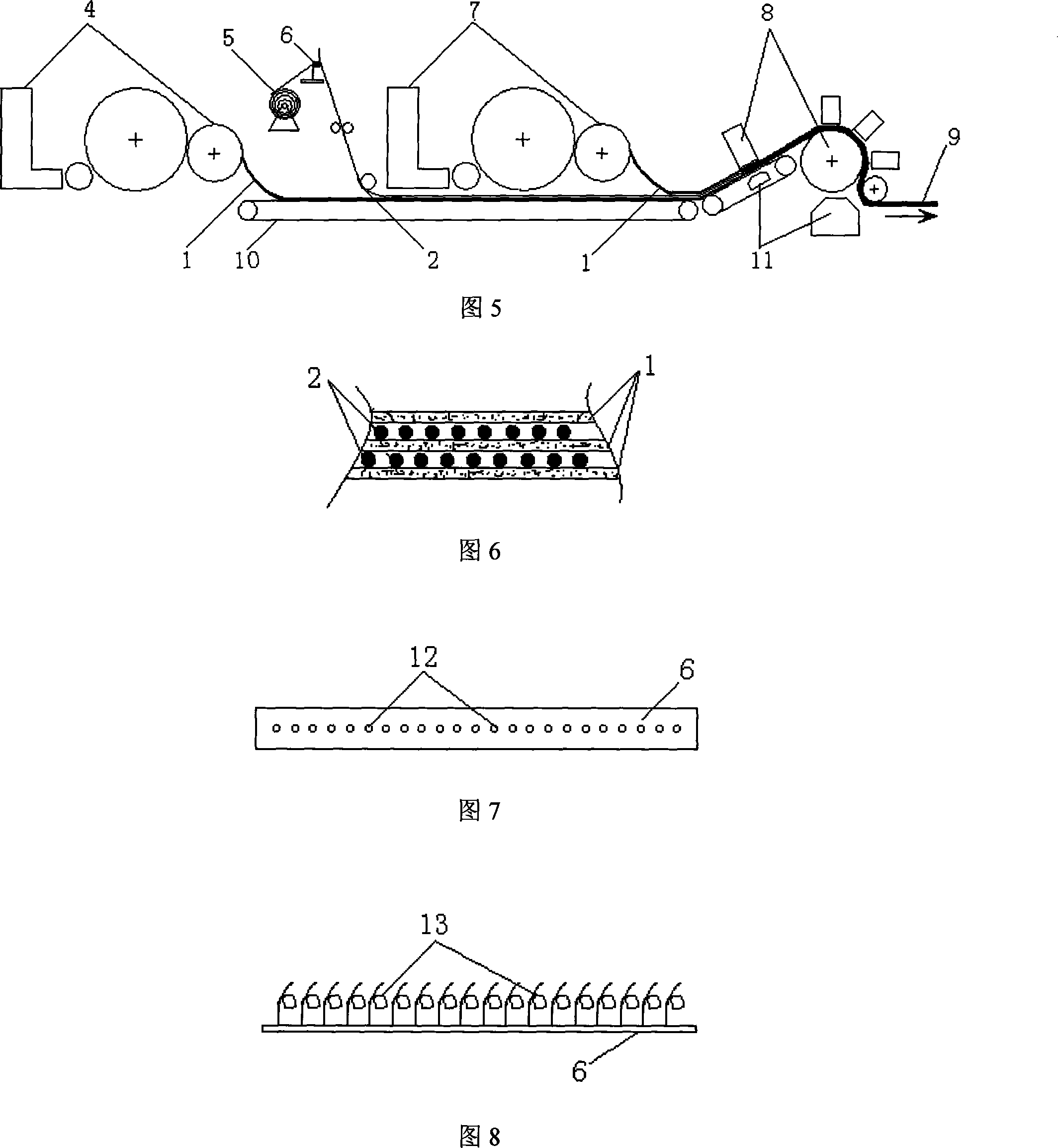

Embodiment 1

[0042] The linear elastic body material 2 is made of spandex filament, its tensile breaking strength is 1.5 cN / dtex, and its tensile breaking elongation is 500%. When the fixed elongation is 100%, the elastic recovery rate is equal to 100%; when the fixed elongation is 300%, the elastic recovery rate is equal to 96%. The fiber 3 used in the two-layer web is 100% PET fiber, the fiber length is 38.0mm, the tensile strength of the single fiber is 4.5cN / dtex, and the tensile elongation at break is 18.5%. The equipment shown in Figure 4, the carding machine 1, the carding machine 2, and the spunlace equipment are all 2.5m wide. The PET fiber is opened and mixed in two ways, and then input into the carding machine 1 and the carding machine 2 respectively. After carding, two layers of fiber webs 1 with single fibrillation and uniform thickness are formed. The weight per unit area of each layer of fiber webs is 25g / m 2 . Wherein the fiber web 1 output by the carding machine 1 is p...

Embodiment 2

[0044] The linear elastic body material 2 is a rubber band with a tensile breaking strength of 3.0 cN / dtex and a tensile breaking elongation of 700%. When the fixed elongation is 100%, the elastic recovery rate is equal to 99%; when the fixed elongation is 300%, the elastic recovery rate is equal to 97%. The fibers 3 used in the two layers of fiber webs are all 50% nylon+50% viscose fibers, and the average length of the fibers is 38.0 mm. The tensile strength of nylon single fiber is 4.0cN / dtex, and the tensile elongation at break is 15%; the tensile strength of viscose is 2.8cN / dtex, and the tensile elongation at break is 20%. As shown in Figure 4, the carding machine 1, carding machine 2, and spunlace equipment are all 1.8m wide. The fiber 3 is opened and mixed in two ways, and then input into the carding machine 1 and the carding machine 2 respectively. After carding, two layers of fiber webs 1 with single fibrillation and uniform surface density are formed. The weight per...

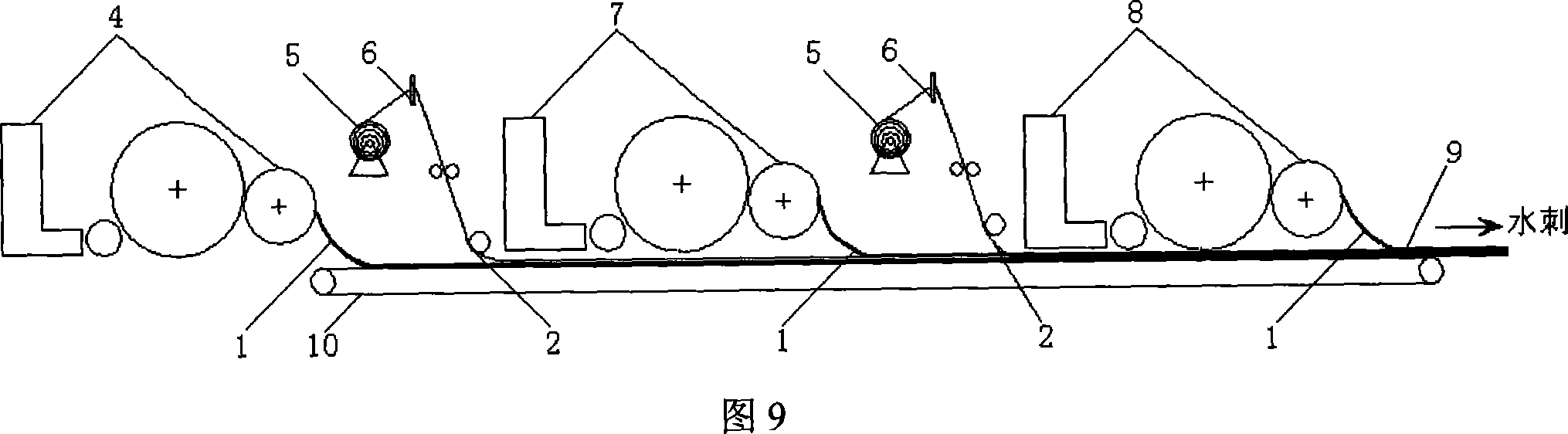

Embodiment 3

[0046] Two rolls of elastic body material spandex core-spun yarn 2 are selected, the tensile breaking strength is 4.5cN / dtex, and the tensile breaking elongation is 450%. When the fixed elongation is 100%, the elastic recovery rate is equal to 99.5%; when the fixed elongation is 300%, the elastic recovery rate is equal to 98%. The fibers 3 used in the three-layer web are all 50% PET+50% viscose fibers, and the average fiber length is 38.0 mm. The tensile strength of PET single fiber is 3.5cN / dtex, and the tensile elongation at break is 20.5%; the tensile strength of viscose single fiber is 3.0cN / dtex, and the tensile elongation at break is 23%. As shown in Figure 4, the width of carding machine 1, carding machine 2, carding machine 3 and spunlace equipment is 2.5m. The fiber 3 is opened and mixed in three ways, and then input into the carding machine 1, carding machine 2 and carding machine 3 respectively. After carding, two layers of fiber webs 1 with single fibrillation and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com