Aerobic particle sludge method for treating town sewage and aerobic particle sludge thereof

A technology for aerobic granular sludge and urban sewage, applied in sustainable biological treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. The problem of high operating costs and the effect of solving sludge bulking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

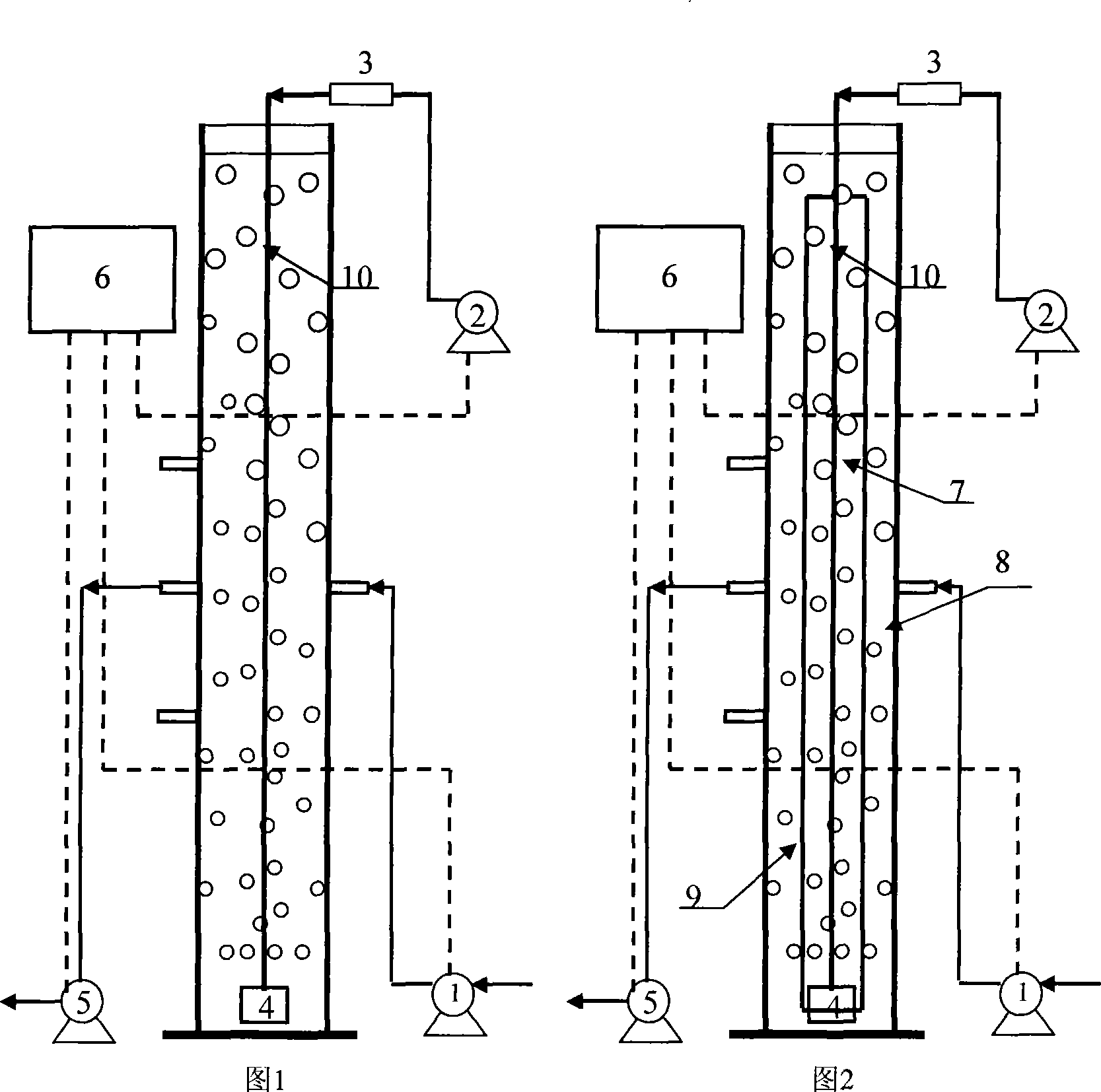

[0013] In this embodiment, the aerobic granular sludge method for treating urban sewage adopts a sequencing batch reactor (SBR) with an aspect ratio of 12. The so-called sequencing batch type is a sewage biological treatment system that operates intermittently; as shown in Figure 1 Shown: The main part of the reactor is a combination of cylindrical plexiglass cylinder and carbon steel. The height of the cylinder is 5.5m. m, the effective volume is 1m 3 The bottom of the reactor is equipped with a microporous aeration head 4, which is connected with an external air compressor 2 by an air pipe 10, and the aeration rate is regulated by a rotameter 3, and the reactor drains water through a solenoid valve 5, and enters water through an inlet pump 1 , the entire process runs automatically under the control of the time program controller 6.

[0014] In this embodiment, the operation process of using the above-mentioned sequencing batch reactor to treat urban sewage to cultivate aero...

Embodiment 2

[0018] In this example, the aerobic granular sludge method for treating urban sewage adopts a sequencing batch airlift reactor (SBAR) with an aspect ratio of 12. The sewage biological treatment system of the flow tube; as shown in Figure 2: the main part of the reactor is a combination of cylindrical plexiglass tube and carbon steel, the height of the lower half of the carbon steel is 3m, and the height of the upper half of the plexiglass is 2.5m , the cylinder is 5.5m high, the inner diameter is 0.5m, and there is a polyvinyl chloride (PVC) guide tube inside, the height is 4.5m, the inner diameter is 0.3m, and the effective volume is 1m 3 ; The vertical area inside the guide tube is the riser tube 7, and the vertical area formed between the guide tube and the outer tube is the settling tube 8; the bottom of the reactor is equipped with a microporous aeration head 4, and the air tube 10 is used. It is connected with the external air compressor 2, the aeration rate is adjusted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com