Novel technique for producing large-particle high-grade soft leonite from potassium mixed salt by hot crystallization

A technology of strontite and potassium mixed salt, applied in the preparation of bisulfate and other directions, can solve problems such as many impurities, and achieve the effects of simple process, large particle size and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

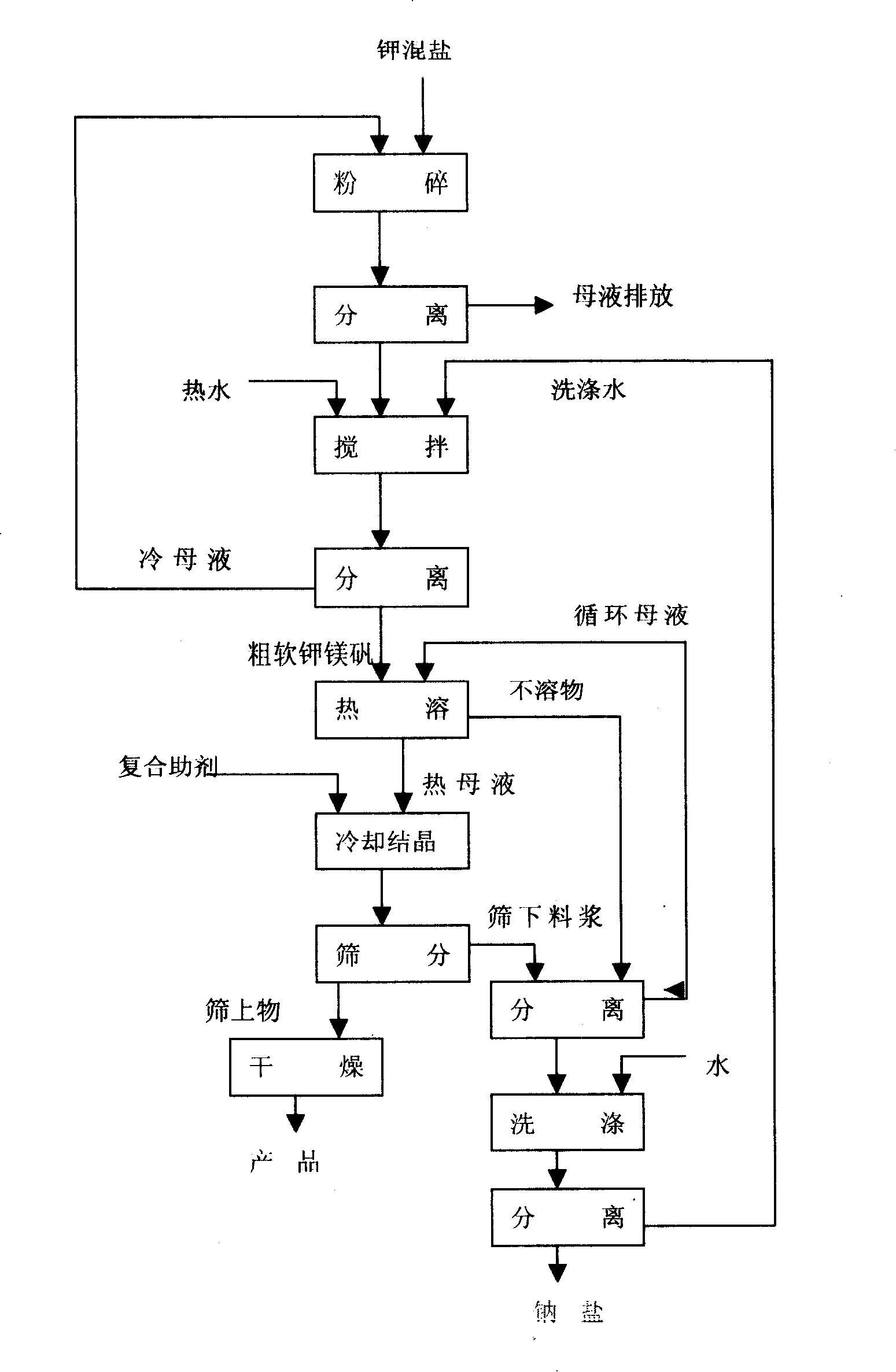

Image

Examples

Embodiment Construction

[0013] 1000g of potassium mixed salt prepared by drying brine in a salt lake contains 16% sodium chloride, 12% magnesium chloride, 8% magnesium sulfate, 32% langbeinite, 30% water, and the total mass component is 98%. After adding the washing mother liquor obtained in the previous reaction process for pulping, pulverize to below 80 mesh, separate the solid and liquid, discard the excess mother liquor, and wash the potassium mixed salt with the solid to contain 7% of magnesium chloride; add sodium salt washing water to the solid, And add a certain amount of hot water, stir for a certain period of time, separate the solid and liquid, and use the mother liquor as the next pulverized raw material to adjust the slurry. The solid material is coarse langbeinite with a sodium content of 20%. Mix the mother liquor, heat to 75-90°C, the insoluble matter is sodium salt, separate the solid from the liquid by pouring, add 30g of compound growth agent to the hot mother liquor, cool down to 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com