Method for desorption of silicon slice

A silicon wafer and desorption technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of low desorption safety of silicon wafers, unfavorable process integration and improve productivity, etc., to achieve high production efficiency, The effect of eliminating residual charge and high process integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

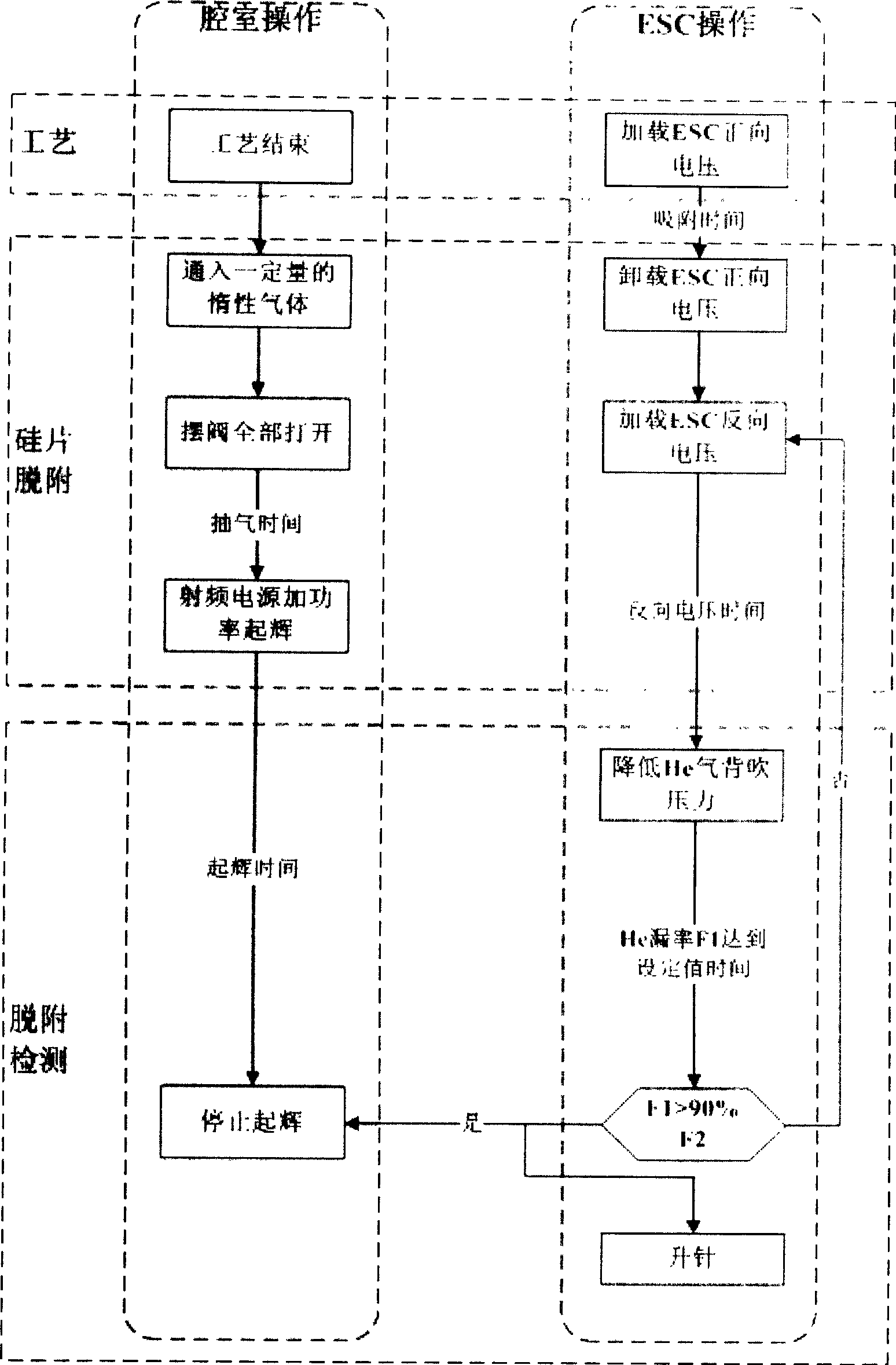

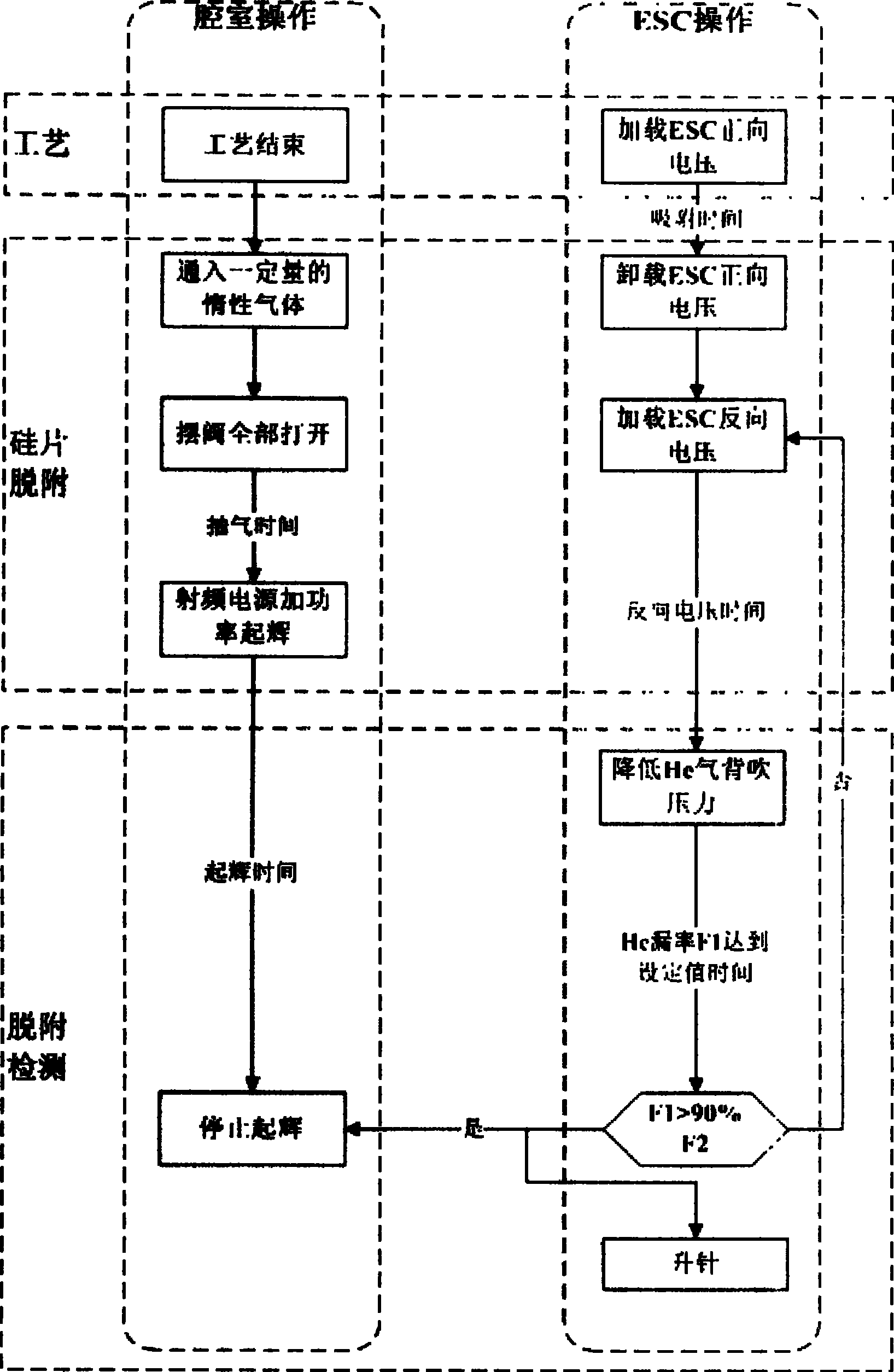

[0024] The preferred embodiment of the method for silicon wafer desorption of the present invention is as follows: figure 1 shown, including

[0025] Step 11. Remove the forward voltage of the electrostatic chuck and increase the reverse voltage to the ESC (electrostatic chuck). The main function of this step is to eliminate the static charge inside the electrostatic chuck by increasing the reverse voltage.

[0026] Step 12: Introduce an inert gas into the reaction chamber, and turn on the radio frequency source to ionize the inert gas into plasma. The main function of this step is to use the conductivity of ions to eliminate the residual charge on the surface of the silicon wafer. At the same time, the residual charge on the surface of the electrostatic chuck is also eliminated.

[0027] Step 13. Judging whether the silicon wafer is desorbed according to the leakage flow rate of the back-blown He gas on the back of the silicon wafer from between the silicon wafer and the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com