Rib type bionic abrasion-proof structure surface

A structural surface and ribbed technology, which is applied in the direction of large containers, pipelines to prevent damage/wear, containers, etc., can solve the problems of increasing the manufacturing cost and use cost of equipment or components, high price, high quality, etc., to improve wear resistance, The effect of reducing contact opportunities and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

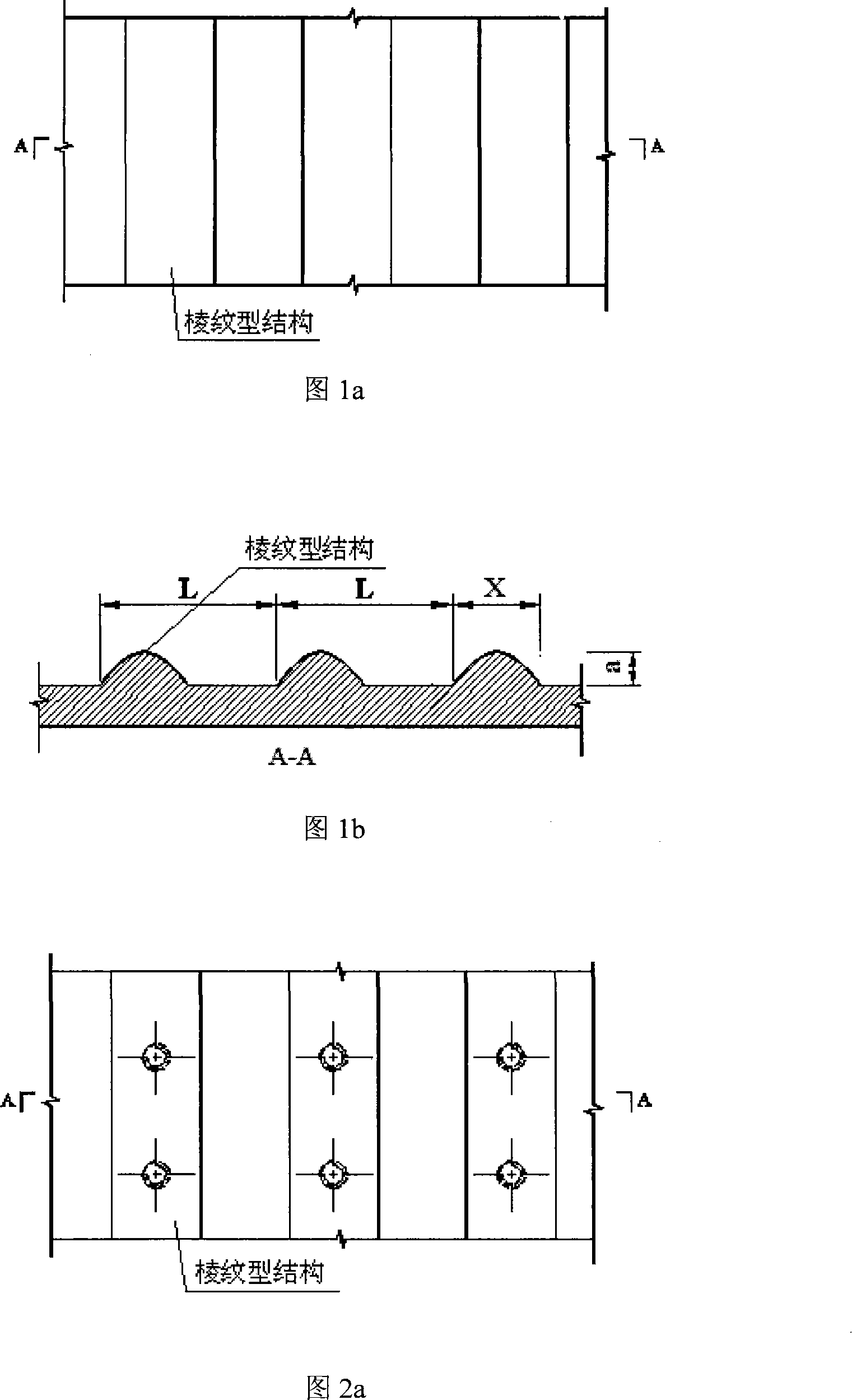

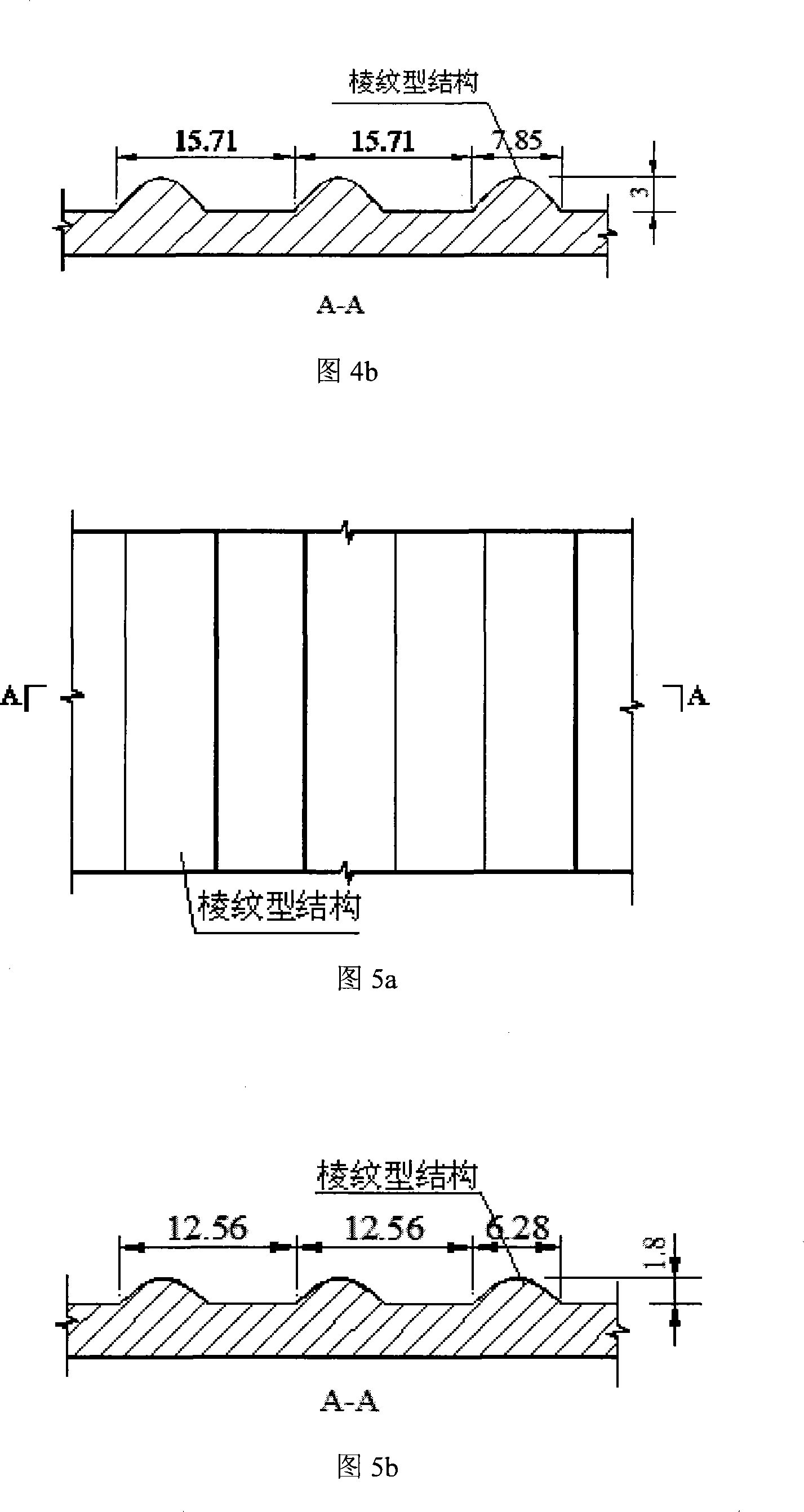

[0021] Refer to Figure 4 (a, b) for Example 1:

[0022] Accompanying drawing 4 is the dimension diagram of the surface of the ribbed bionic structure of a certain part. The part has been subjected to the abrasive wear of bulk materials (particle size is 0.214-0.420mm, and the sliding speed of the bulk materials on the surface is 2.35m / s) for a long time. In the figure, according to the size of the material, the sliding speed of the material on the surface, and the size of the mechanism or parts, the height of the rib is 3 mm, and the aspect ratio of the rib is 3:7.85, so that the definition domain of the half cycle of the sine function is ( 0, 7.85), assign specific values to a, b, and c, respectively, a=3, b=0.4, c=0. That is, the contour equation of the ribbed structure on the wear-resistant surface is: y=3sin(0.4x). The spacing L of the rib structure is: 15.71mm. Practice shows that the structure is significantly better than the wear performance of ordinary smooth plan...

example 2

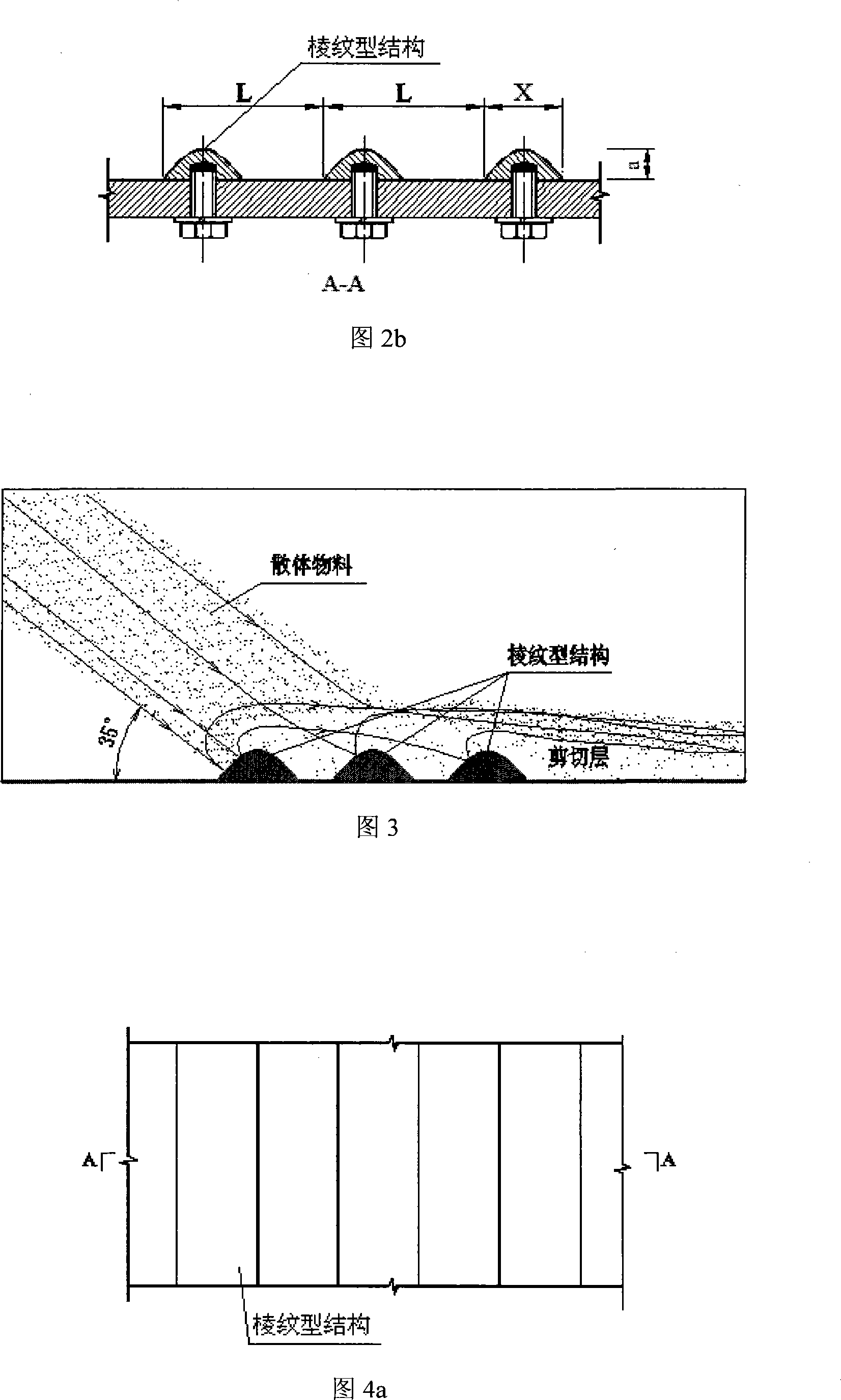

[0023] Example 2 referring to Fig. 5 (a, b):

[0024] Accompanying drawing 5 is the dimension diagram of the surface of the ribbed bionic structure of a certain part. In actual work, the particle size of the bulk material is 0.104-0.214mm, and the sliding speed of the bulk material on the surface is 3.02m / s. In the figure, according to the size of the material, the sliding speed of the material on the surface and the size of the mechanism or parts, the height of the rib is 1.8mm, and the aspect ratio of the rib is 1.8:6.28, so that the definition domain of the half cycle of the sine function is (0, 6.28), assign specific values to a, b, and c, respectively, a=1.8, b=0.5, and c=0. That is, the contour equation of the ribbed structure on the wear-resistant surface is: y=1.8sin(0.5x). The spacing L of the rib structure is: 12.56mm. Practice shows that the structure is significantly better than the wear performance of ordinary smooth plane parts. Under the same working condit...

example 3

[0025] Example 3 is referring to Fig. 6 (a, b):

[0026] Accompanying drawing 6 is the dimension diagram of the surface of the ribbed bionic structure of a certain part. In actual work, the particle size of the bulk material is 0.420-0.840mm, and the sliding speed of the bulk material on the surface is 1.68m / s. In the figure, according to the size of the material, the sliding speed of the material on the surface and the size of the mechanism or parts, the height of the rib is 1.2 mm, and the aspect ratio of the rib is 1.2:5.23, so that the definition domain of the half cycle of the sine function is (0, 5.23), assign specific values to a, b, and c, respectively, a=1.2, b=0.6, and c=0. That is, the contour equation of the ribbed structure on the wear-resistant surface is: y=1.2sin(0.6x). The spacing L of the rib structure is: 9.42mm. Practice shows that the structure is significantly better than the wear performance of ordinary smooth plane parts. Under the same working con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com