Electrostatic cut-off device

A current interceptor and electrostatic technology, which is applied in the electrolysis process and electrolysis components, etc., can solve the problems of reduced service life of heat exchange equipment and electrostatic corrosion of heat exchange equipment, and achieve the effects of avoiding corrosion, saving equipment investment, and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

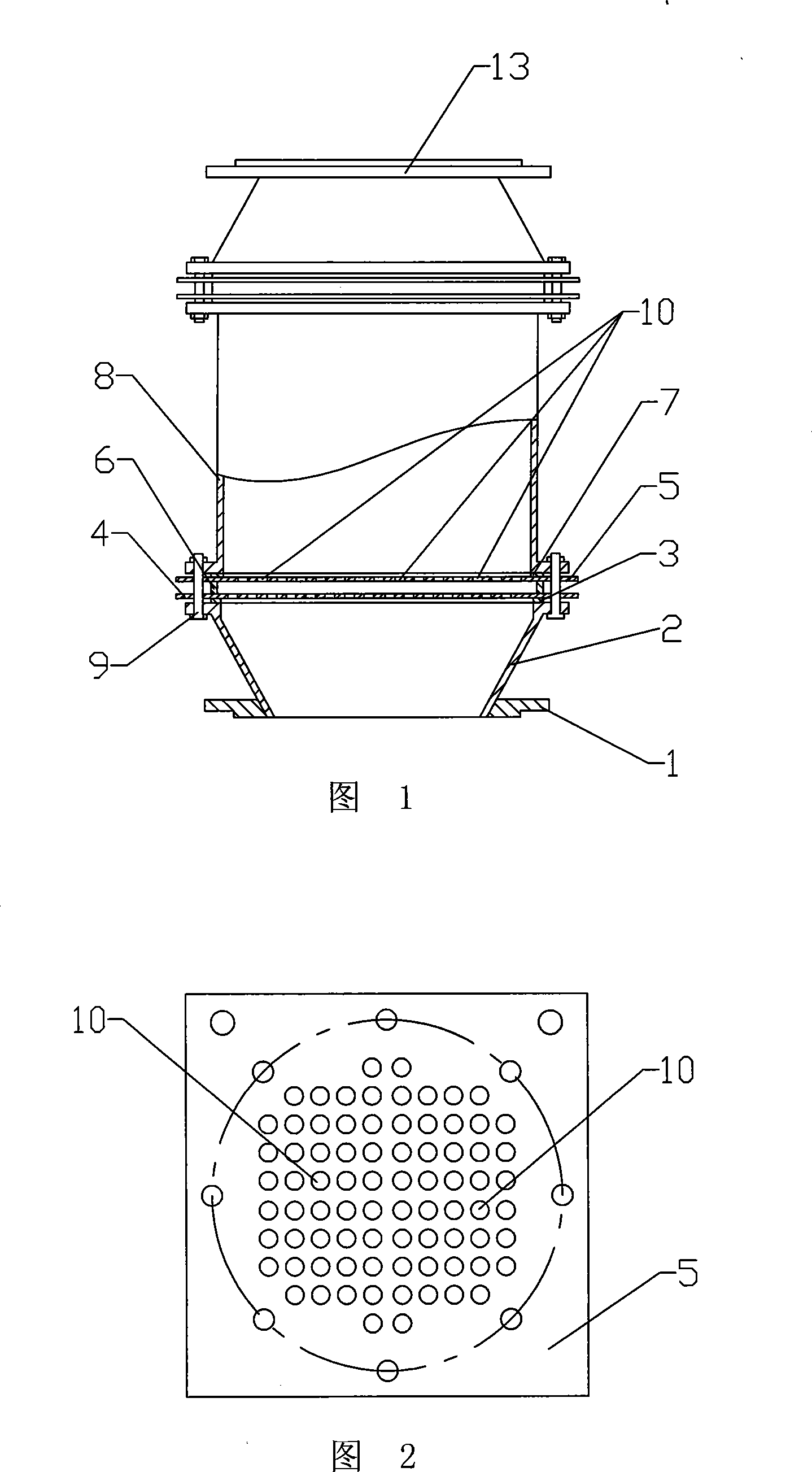

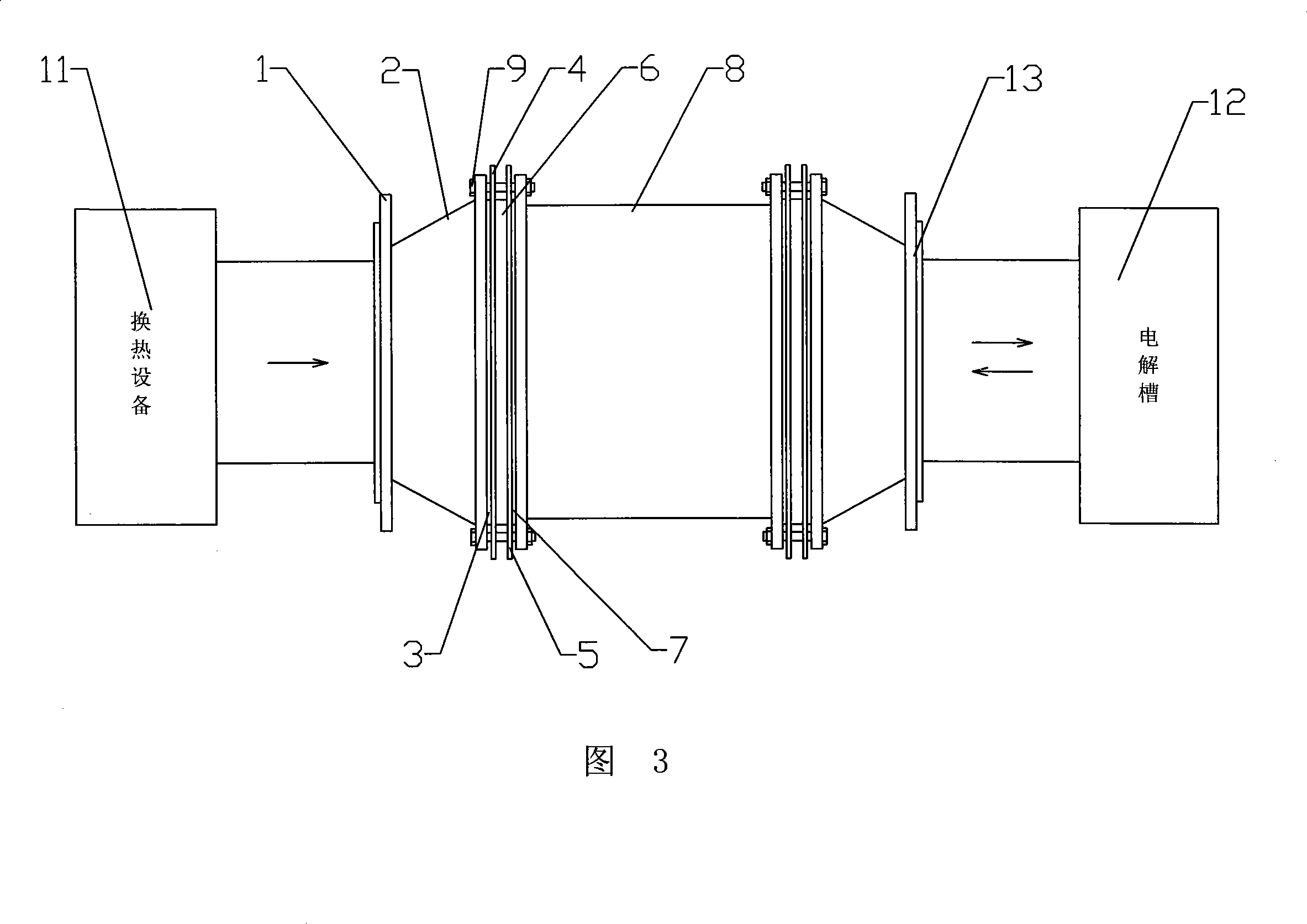

[0021] 1-flange, 2-conical cylinder, 3, 7-asbestos insulating gasket, 4,5-cut-off plate, 6-isolation ring plate, 8-cylinder, 9-bolt, 10-screen hole, 11-change Thermal equipment, 12-electrolyzer, 13-flange

[0022] Embodiment, as shown in Figure 1, an electrostatic interceptor, the interceptor includes a cylinder with two ends open, the two ends of the cylinder are conical cylinders 2, and the ends of the conical cylinder 2 are fixedly welded with flanges 1 , flange 13, the middle is a cylinder 8, the inner diameter of the middle cylinder 8 is greater than the inner diameter of flange 1 and flange 13 at the opening of the tapered cylinder 2 at both ends, and the cylinder seal is provided with two groups of red copper plates perpendicular to the axis of the cylinder. Cut-off plates, each set of red copper cut-off plates includes two cut-off plates 4 and 5 cut-off plates, the cut-off plates 4 and 5 are grounded, and the grounding wire is embedded in the soil with a depth of 1.5 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com