Antibiotic cleaning agent composition using cereal fermentation liquor as main component

A technology of composition and fermentation broth, applied in detergent compositions, non-surface-active detergent compositions, non-ionic surface-active compounds, etc., can solve the problems of uneven utilization rate of production capacity, and achieve low toxicity and high biodegradability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] Preparation of hop meal extract

[0020] Take the dried hop dregs, which are the by-products of brewing beer, grind them into powder, extract them with solvent: hop dregs = 2:1 (W / W) by shaking and extracting for 1 hour, and filter to obtain the hop dregs extract; wherein, the The above-mentioned solvents are hot water at 70° C., 50% alcohol at 70° C. and monopropolene glycol.

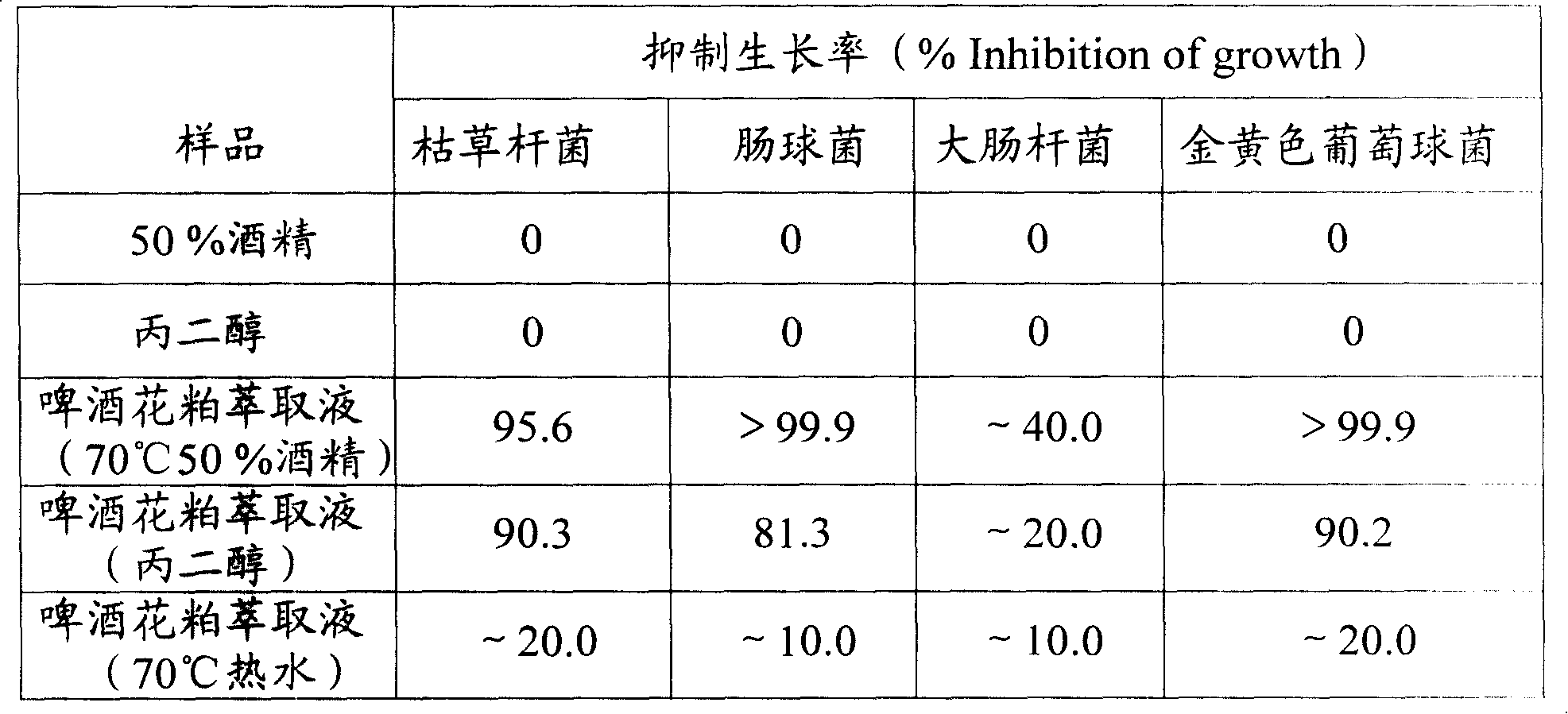

[0021] Antibacterial activity of hop meal extract

[0022]The strains used for the test were B. subtilis, E. faecalis, E. coli, P. aeruginosa and S. aureus. The test method is as follows:

[0023] 1. Preparation of the test bacteria solution: prepare 1.0×10 with 0.5% sterile saline (pH=7.2) 6 cfu / mL of the suspension of each of the above test bacterial strains.

[0024] 2. Antibacterial effect test: Take 0.3 mL of the above-mentioned hop dregs extract, add water to dilute to 10 mL, and add 0.1 mL of test bacteria liquid. After mixing well, let it stand for 10 minutes. Take 0.1 mL of th...

Embodiment 1

[0029] The cleanser composition of embodiment one comprises:

[0030] 3wt% hop dregs 70°C 50% alcohol extract; 22wt% coconut oleic acid ester; 75wt% grain fermentation liquor.

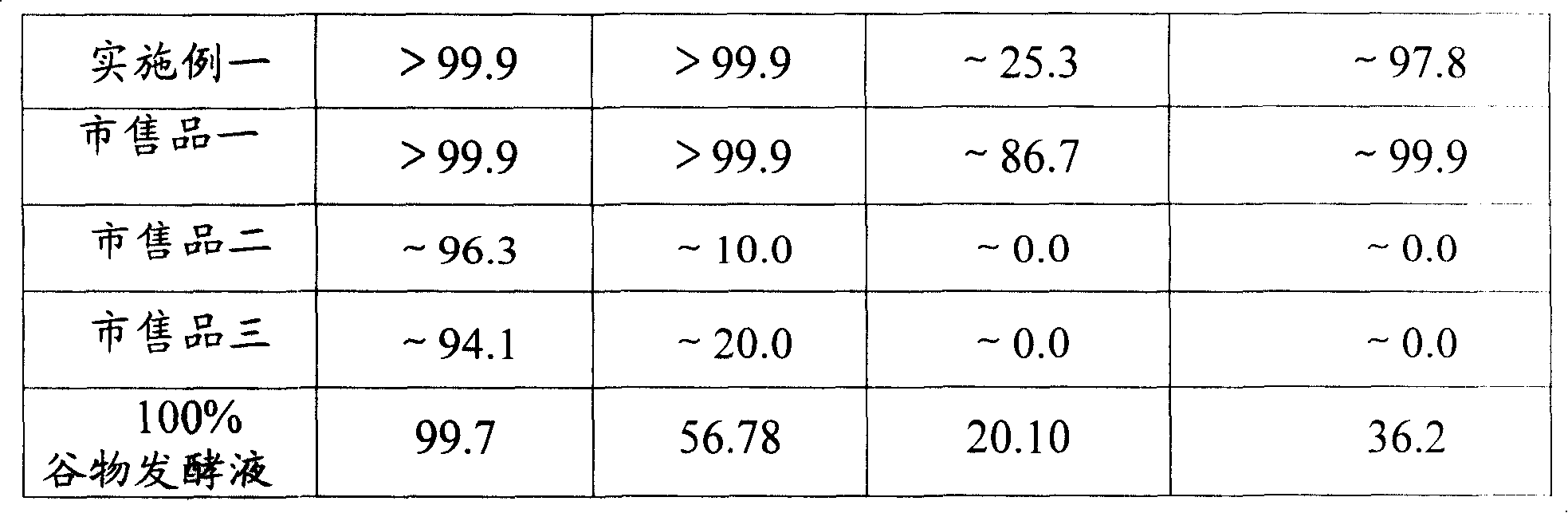

[0031] Bacteriostasis test:

[0032] Carry out the test of the ability to inhibit microbial proliferation as the above-mentioned hop dregs extract, the test strain is the same as above, and the test method is as follows: take 0.1mL of bacterial liquid, add it to 0.3mL of water and dilute it into 10mL of detergent and mix it, and let it stand for 10 minutes; Take 0.1 mL of the above mixture and spread it on tryptic soy agar, repeat each treatment five times, place it in a 37°C incubator, and count the number of colonies after 24 hours. The results are shown in Table 2 below.

[0033] Table 2. Bacteriostasis evaluation of detergents.

[0034]

[0035]

[0036] From the results in Table 2, it can be seen that the cleaning agent of Example 1, which contains hop dregs extract in its composition, ca...

Embodiment 2

[0038] The cleanser composition of embodiment two comprises:

[0039] Any one of the hop dregs extract in Table 1: 3wt%; coconut oleic acid ester: 22wt%; grain fermentation liquid: 75wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com