Improved decorating machine

A technology for printing machines and inkjet print heads, applied in printing machines, rotary printing machines, screen printing machines, etc., can solve the problems of single processing method, high production cost, timeliness, poor networking, etc. Function, low processing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

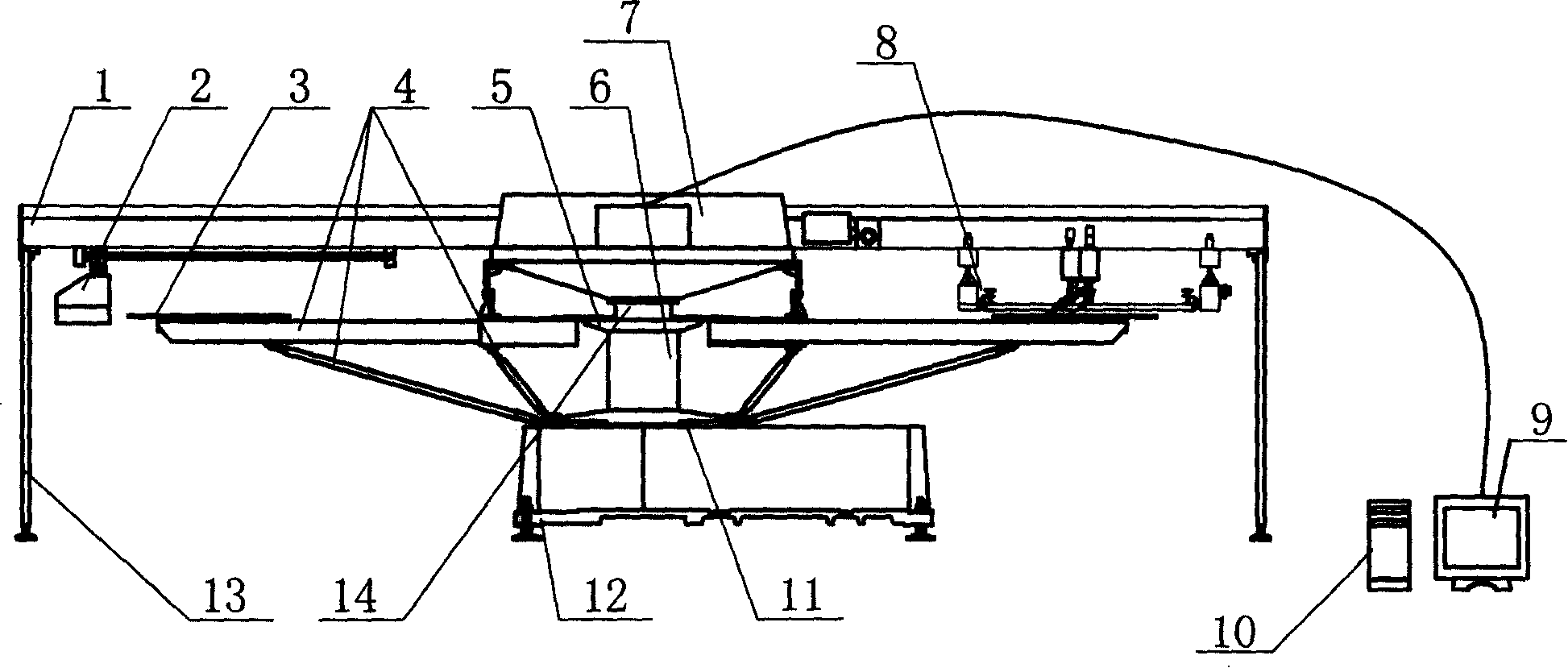

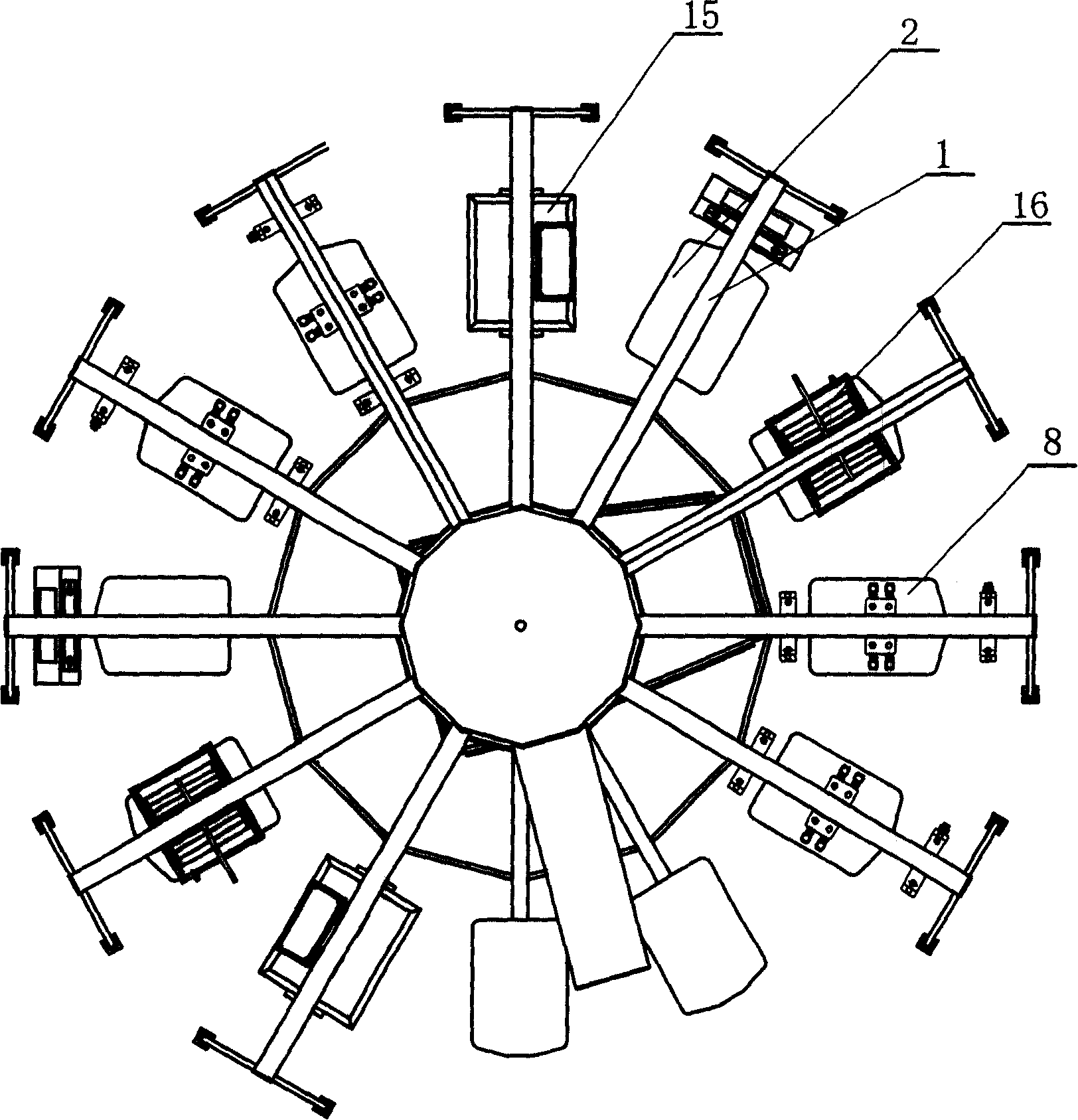

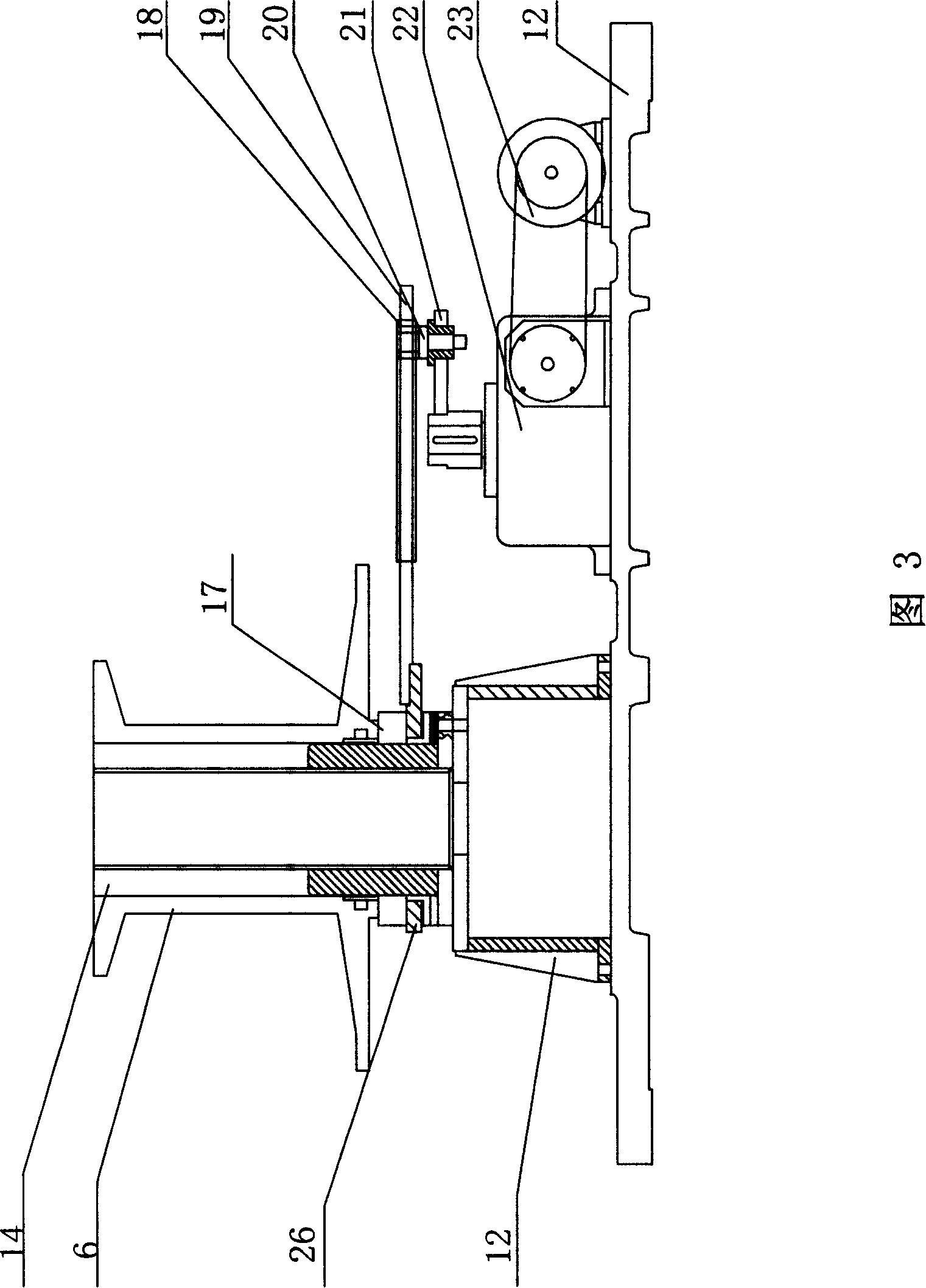

[0023] Example 2 see Figure 6 , Figure 7 , the support frame includes a girder 1, one end of the girder 1 is connected to the top plate 7 respectively, the top plate 7 is set on the upper end of the column 14, the middle part of the girder 1 is respectively connected to the piston rod of the cylinder 31, and the cylinder 31 is installed on the top plate 7; Inkjet printing head 2, screen frame 8, flocking box 16, and drying box 1 5 are respectively installed on the girder 1; the cylinder 31 is electrically connected to the programmable logic controller 10, and the multi-station workbench, rotating structure and implementation Example 1 is the same, except that the bottom of the rotating structure does not need to establish a cylinder 30. After each process is finished, the cylinder 31 drives the inkjet print head 2, the silk screen frame 8, the flocking box 16 and the drying box 15 to go up, and at the same time, The workbench rotates one station, and then the cylinder 31 dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com