Feed fabricating method for special animal such as fox, ermine and raccoon dog

A technology of animal feed and manufacturing method, which is applied in the direction of animal feed, animal feed, feed, etc., can solve the problems of feed safety due to incomplete sterilization, poor product water holding capacity and palatability, and reduce the nutritional content of feed products, so as to improve Effects of lactation volume and milk quality, increasing seed selection space, and reducing sperm deformity rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

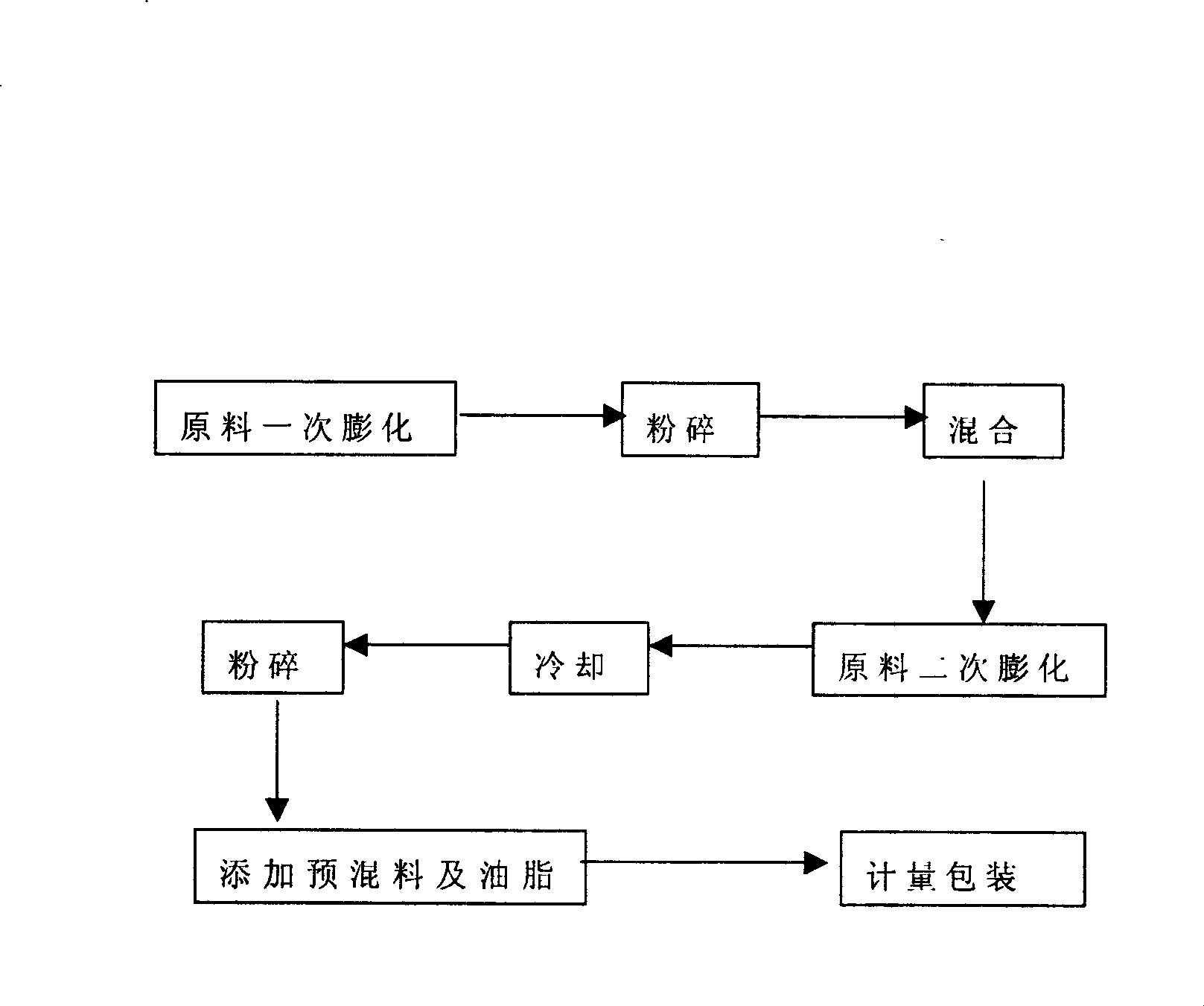

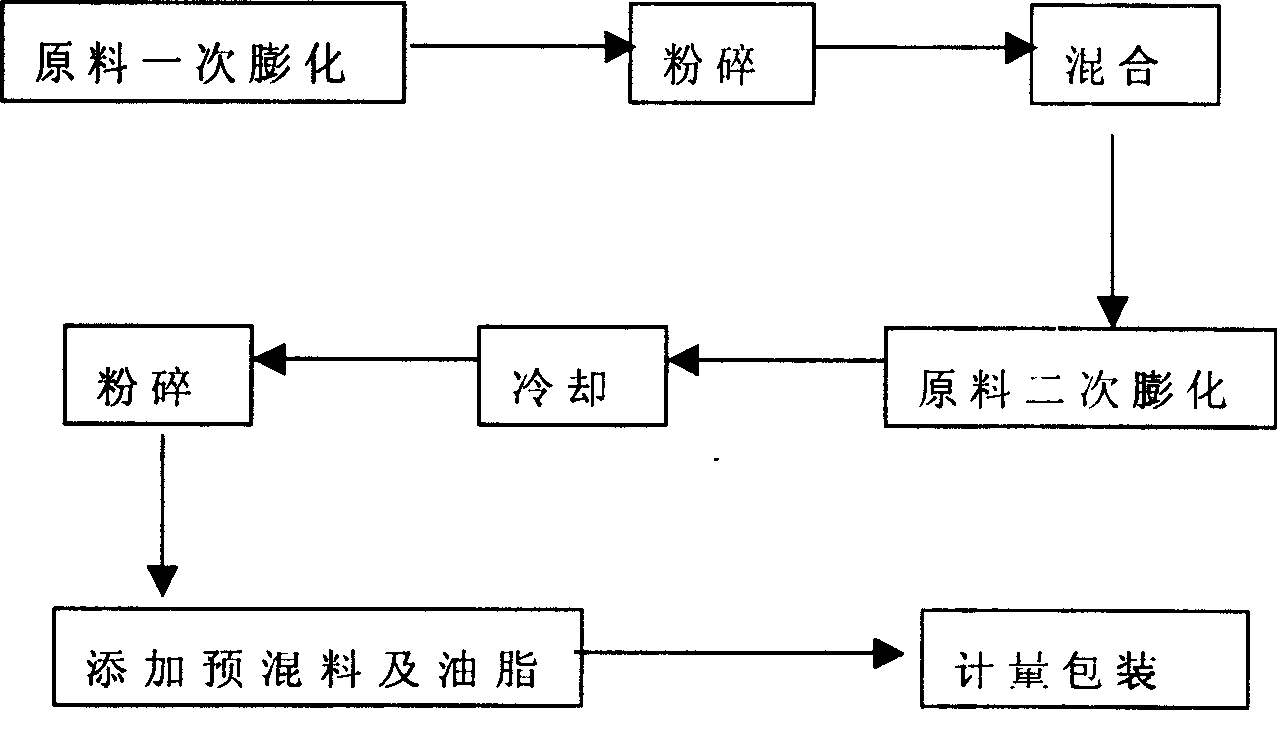

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: Take processing 1000 kilograms of mink material as example

[0034] 1. Select raw materials according to the formula: 365 kg of corn, 220 kg of soybean meal, 250 kg of meat and bone meal, 120 kg of imported fish meal, and 5 kg of salt. Corn and soybean meal are extruded by dry or wet method. After puffing, it is sent to a hammer mill for crushing. The aperture of the sieve plate of the crusher is 0.8-1.2 mm. After crushing, the material is sent to the batching raw material bin for use.

[0035] 2. Mix 365 kg of corn, 220 kg of soybean meal, 250 kg of meat and bone meal, 120 kg of imported fish meal, and 5 kg of salt (without adding premix and oil) to the above-mentioned puffed raw materials. Evenly, mix 960kg each time.

[0036] 3. The mixed material is sent to the raw material bin of the extruder for secondary expansion. The front end of the secondary expansion extruder adopts an annular gap discharge die, the expansion temperature is 100-130°C, and the ...

Embodiment 2

[0040] Embodiment 2: Taking the addition of 1000 kilograms of fox material as an example

[0041] 1. Select raw materials according to the formula: 575 kg of corn, 280 kg of soybean meal, 70 kg of meat and bone meal, 40 kg of imported fish meal, and 5 kg of salt. Corn and soybean meal are extruded by dry or wet method. After puffing, it is sent to a hammer mill for crushing. The aperture of the sieve plate of the crusher is 0.8-1.2 mm. After crushing, the material is sent to the batching raw material bin for use.

[0042] 2. Mix 575 kg of corn, 280 kg of soybean meal, 70 kg of meat and bone meal, 40 kg of imported fish meal, and 5 kg of salt (without adding premix and oil) to the above-mentioned puffed raw materials. Evenly, mix 970kg each time.

[0043] 3. The mixed material is sent to the raw material bin of the extruder for secondary expansion. The front end of the secondary expansion extruder adopts an annular gap discharge die, the expansion temperature is 100-130°C, and...

Embodiment 3

[0047] Embodiment 3: Take processing 1000 kilograms of raccoon dogs as an example

[0048]1. Select raw materials according to the formula: 595 kg of corn, 290 kg of soybean meal, 80 kg of meat and bone meal, 0 kg of imported fish meal, and 5 kg of salt. Corn and soybean meal are extruded by dry or wet method. After puffing, it is sent to a hammer mill for crushing. The aperture of the sieve plate of the crusher is 0.8-1.2 mm. After crushing, the material is sent to the batching raw material bin for use.

[0049] 2. Mix 595 kg of corn, 290 kg of soybean meal, 80 kg of meat and bone meal, 0 kg of imported fish meal, and 5 kg of salt (without adding premix and oil) to the above-mentioned puffed raw materials. Evenly, mix 970kg each time.

[0050] 3. The mixed material is sent to the raw material bin of the extruder for secondary expansion. The front end of the secondary expansion extruder adopts an annular gap discharge die, the expansion temperature is 100-130°C, and the outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com