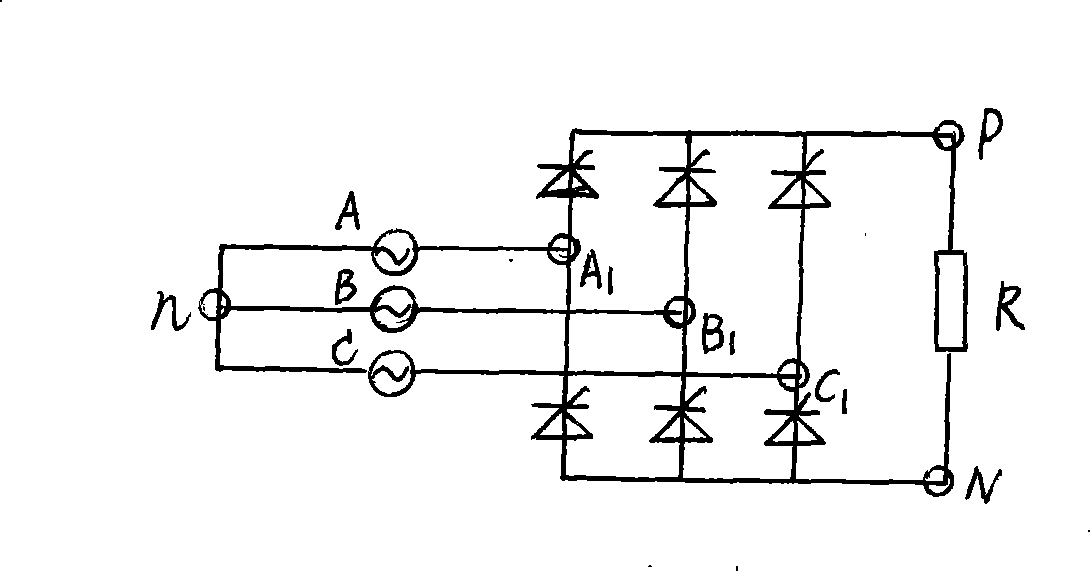

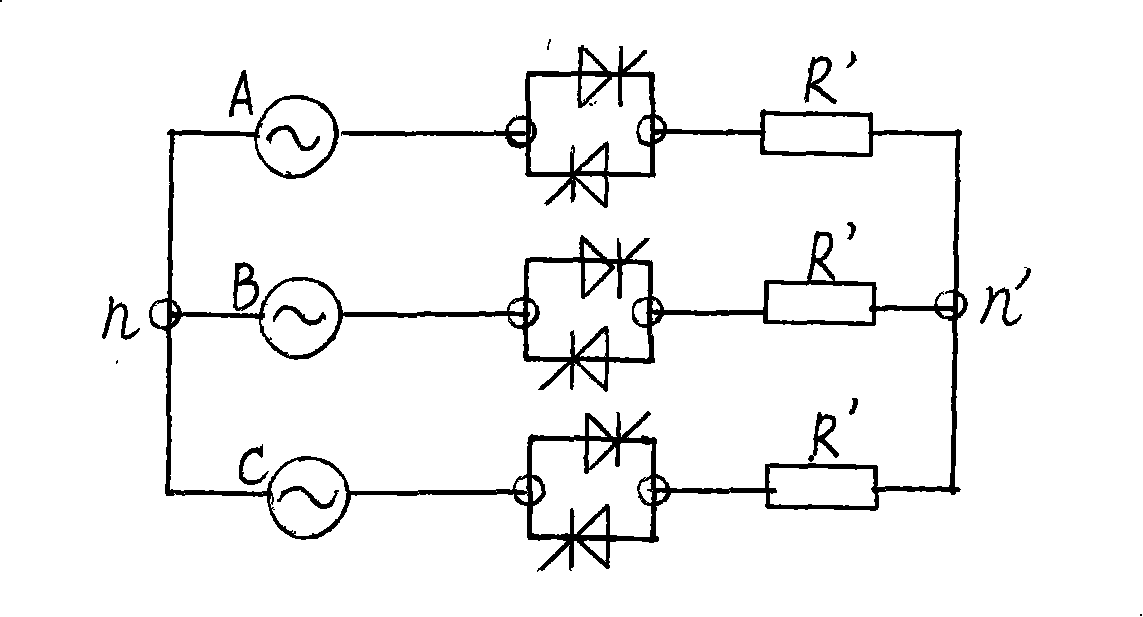

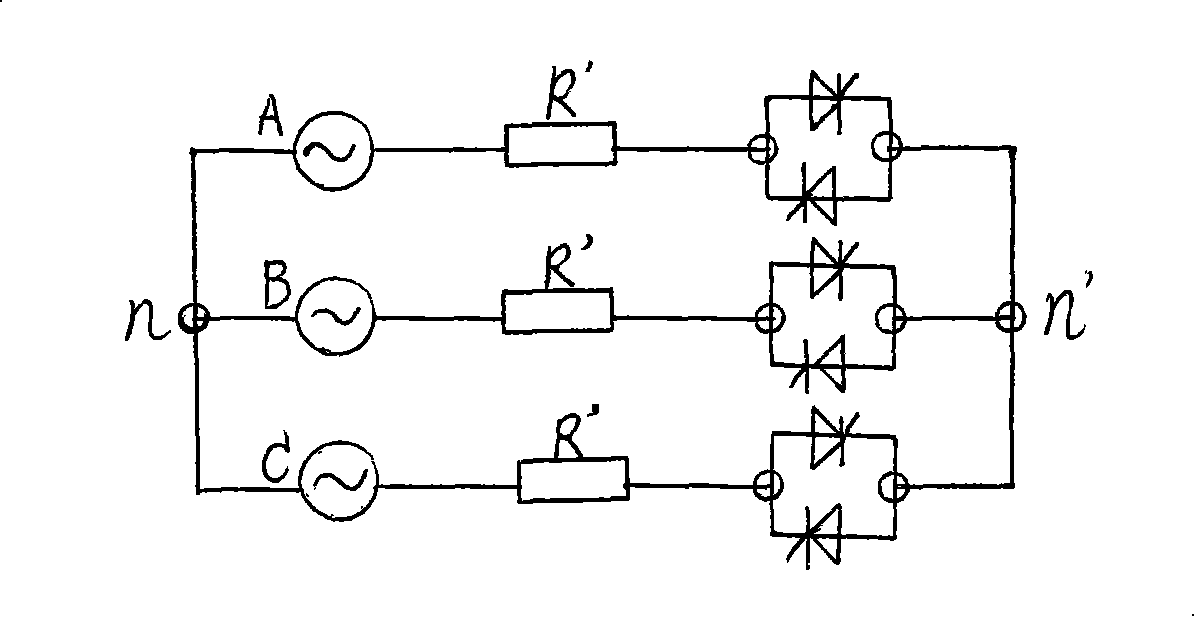

Low-voltage and high-voltage motor soft starter composed of three-phase commutation bridge

A soft starter, three-phase AC technology, applied in the direction of motor generator/starter, single multi-phase induction motor starter, etc., can solve the problems of high cost, waste of electric energy, technical complexity, etc., and achieve convenient electrical isolation, The effect of improving circuit connection and simplifying the composition structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]The common trend in the development of power semiconductor switching devices in the past 10 years is modularization, that is, connecting and installing together semiconductor switching devices of the same type and one or more switching devices of different types according to a certain circuit topology. This combination is called power semiconductor modules. If the information electronic circuits such as driving or triggering, control and protection in the power switching device are also fabricated on an integral chip, it is called an intelligent power integrated circuit or an intelligent power module. Among them, the "six-unit" (that is, composed of six identical thyristors) three-phase fully-controlled rectifier modules are most widely used. The modularization and intelligentization of power switching devices simplifies the structure of power units, reduces circuit connections, reduces the volume of power converters, reduces power supply or device costs, improves operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com