Method for suitable for batch quantity hot dipping zinc of rolled steel

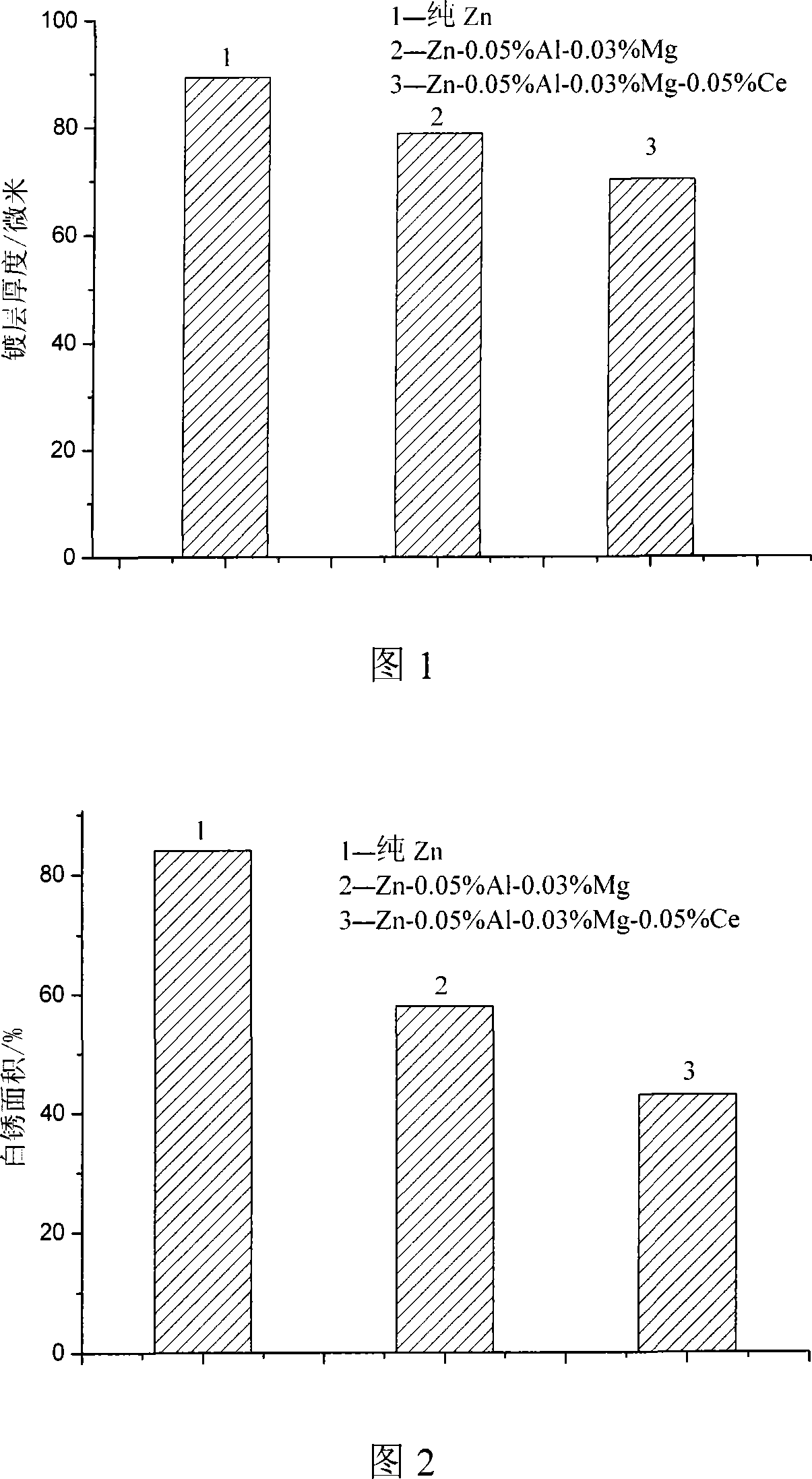

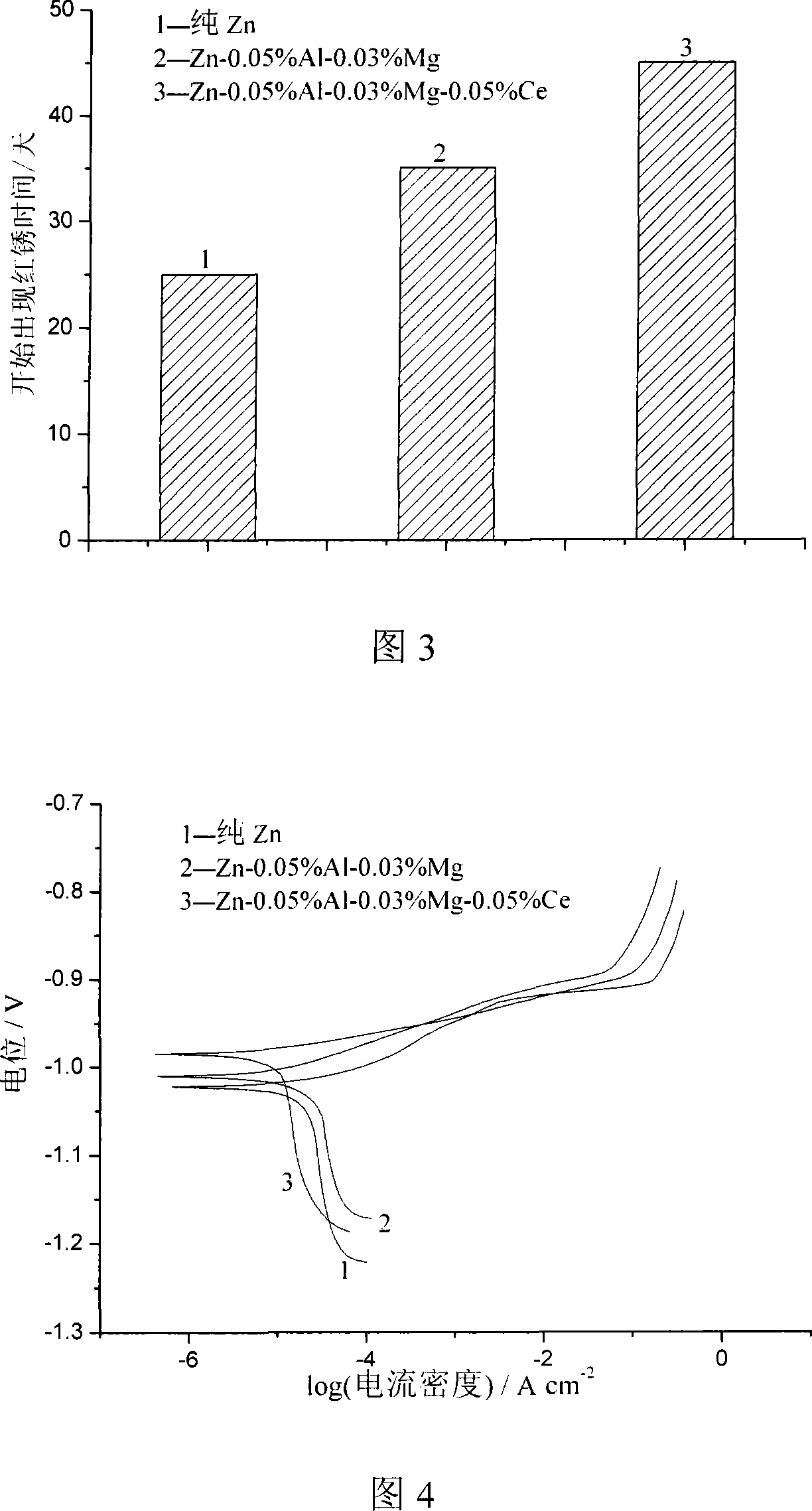

A technology of hot-dip galvanizing and steel, applied in hot-dip galvanizing process, chemical variable control, non-electric variable control and other directions, can solve the problem of difficult to control the exact content, change, consumption speed of zinc bath, etc. The effect of large-scale production of hot-dip galvanizing, reducing the thickness of the coating and delaying the formation of white rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The steel used for galvanizing is a steel plate containing 0.18% Si, and the chemical composition is shown in Table 1 below. The batch hot-dip galvanizing method adopted includes the following steps and process conditions:

[0023] (1) Binary master alloy refining: Weigh aluminum and zinc, magnesium and zinc, cerium and zinc in proportion by weight, place them in graphite crucibles, and refine them respectively. Among them: the aluminum content in the zinc-aluminum binary master alloy is 5%, the melting temperature of the zinc-aluminum master alloy is 680°C, and the holding time is 2 hours; the magnesium content in the zinc-magnesium binary master alloy is 4%, and the zinc-magnesium master alloy The smelting temperature of the zinc-cerium master alloy is 650°C, and the holding time is 4 hours; the cerium content in the zinc-cerium binary master alloy is 3.3%, and the melting temperature of the zinc-cerium master alloy is 760°C, and the holding time is 4 hours. After ea...

Embodiment 2

[0037] The steel used for galvanizing is a Q235 (0.22% Si) steel plate, which is hot-dip galvanized for 5 minutes in a pure zinc bath with a bath temperature of 450 ° C and an alloy zinc bath containing aluminum, magnesium and cerium. Wherein the hot-dip galvanizing in the alloy zinc bath comprises the following steps and process conditions:

[0038](1) Binary master alloy refining: by weight ratio) aluminum and zinc, magnesium and zinc, cerium and zinc are respectively placed in graphite crucibles and refined separately. Among them: the aluminum content in the zinc-aluminum binary master alloy is 4%, the melting temperature of the zinc-aluminum master alloy is 700°C, and the holding time is 1 hour; the magnesium content in the zinc-magnesium binary master alloy is 3.6%, and the zinc-magnesium master alloy The smelting temperature of the zinc-cerium master alloy is 680°C, and the holding time is 3 hours; the cerium content in the zinc-cerium binary master alloy is 3%, and the ...

Embodiment 3

[0043] The steel used for galvanizing is a Q235 (containing 0.22% Si) steel plate, which is hot-dip galvanized for 5 minutes in a pure zinc bath with a bath temperature of 450 ° C and an alloy zinc bath containing aluminum, magnesium and cerium. Wherein the hot-dip galvanizing in the alloy zinc bath comprises the following steps and process conditions:

[0044] (1) Binary master alloy refining: Weigh aluminum and zinc, magnesium and zinc, cerium and zinc in proportion by weight, place them in graphite crucibles, and refine them separately. Among them: the aluminum content in the zinc-aluminum binary master alloy is 4.8%, the melting temperature of the zinc-aluminum master alloy is 680°C, and the holding time is 2 hours; the magnesium content in the zinc-magnesium binary master alloy is 3%, and the zinc-magnesium master alloy The smelting temperature of the zinc-cerium master alloy is 680°C, and the holding time is 3 hours; the cerium content in the zinc-cerium binary master al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com