Piston for a working cylinder

A technology of working cylinders and pistons, which is applied in the direction of pistons, cylindrical pistons, plungers, etc., can solve the problems of time-consuming, high manufacturing and assembly costs, and achieve the effect of simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

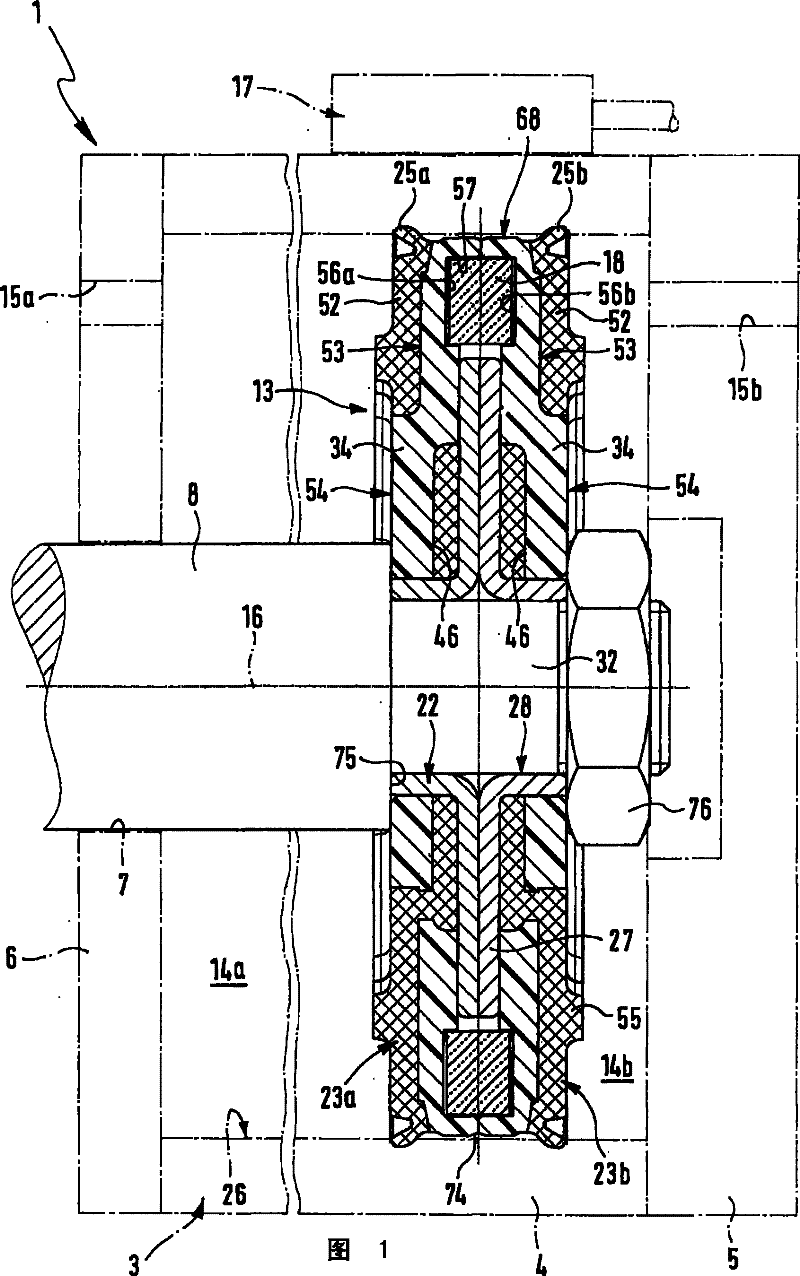

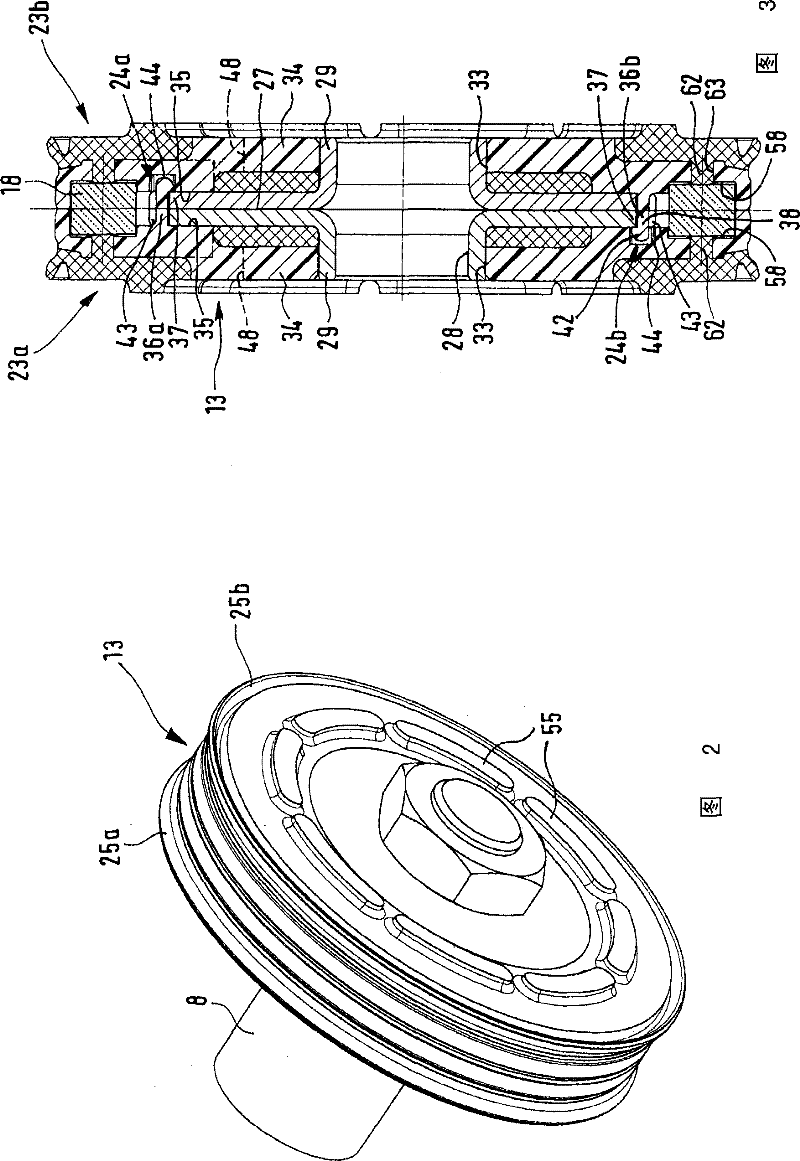

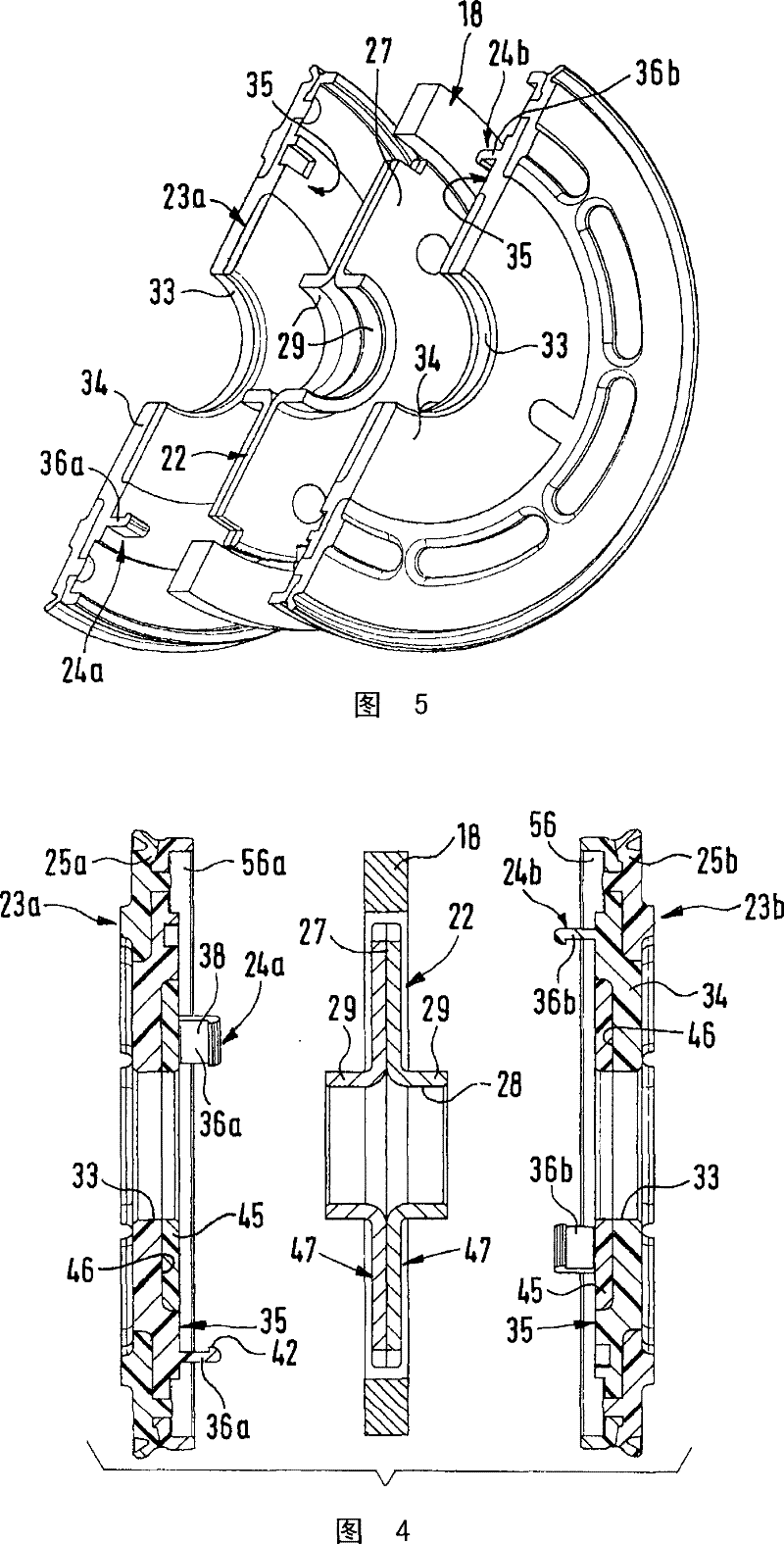

[0035] figure 1A fluid-actuated working cylinder, which is designated in its entirety with the reference numeral 1 , is shown in part only schematically and with dot-dash lines. It is especially suitable for working with compressed air, but of course it can also be propelled by another gas medium or hydraulic medium.

[0036] The cylinder 1 has a cylinder housing 3 with a cylinder liner 4 which is closed at the rear by an end cover 5 and at the front by a support cover 6 . The support cover is penetrated by a central through-hole 7, in which guide and sealing devices, not shown in detail, are arranged, which together with a piston rod 8 passing through the through-hole 7 play a guiding and sealing role. A piston 13 according to a preferred embodiment of the invention is attached to the end of the piston rod 8 arranged inside the cylinder housing 3, the piston dividing the interior of the cylinder housing 3 into two axially arranged The cylinder chamber 14a, 14b.

[0037] A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com