Protective coating for window glass

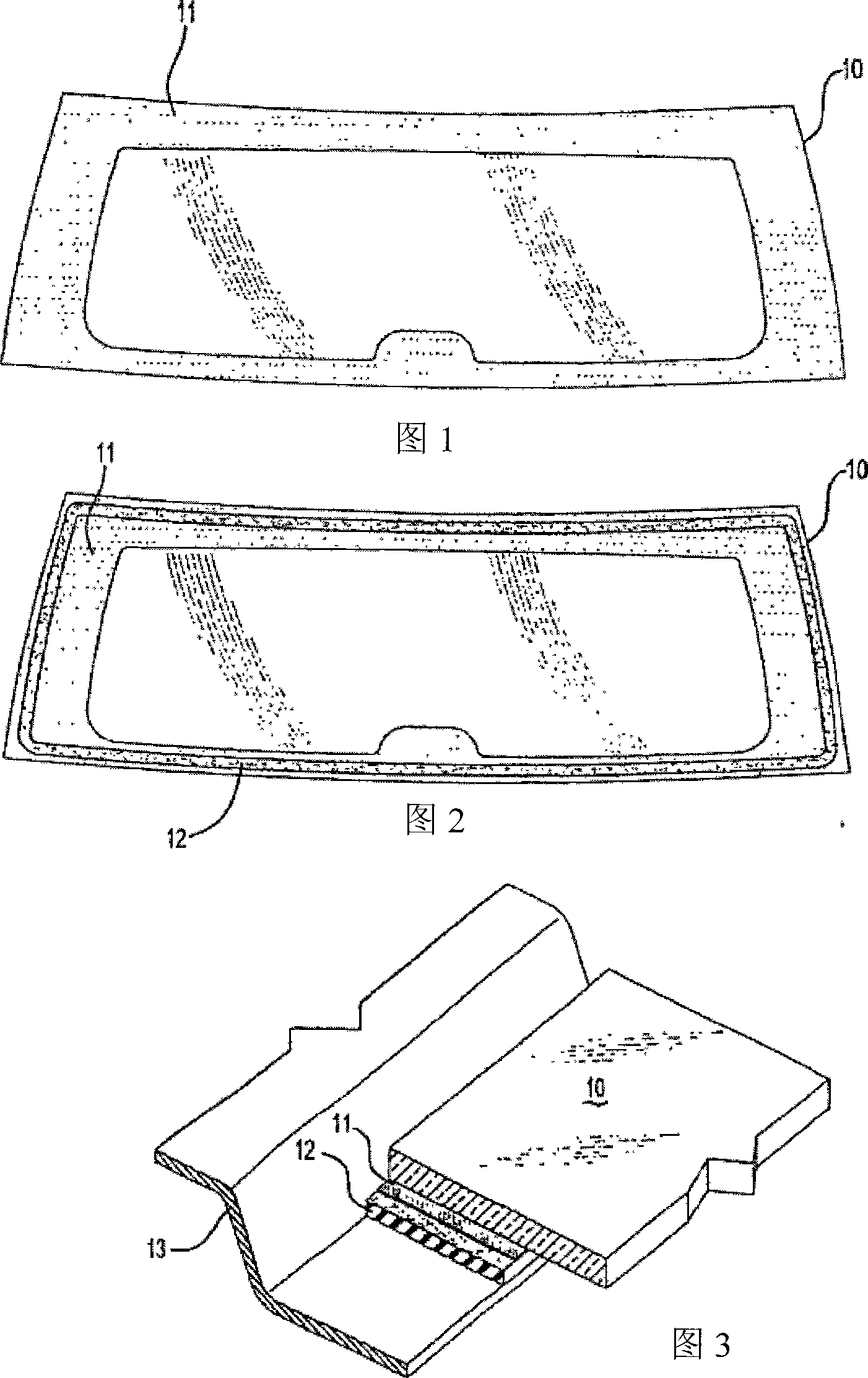

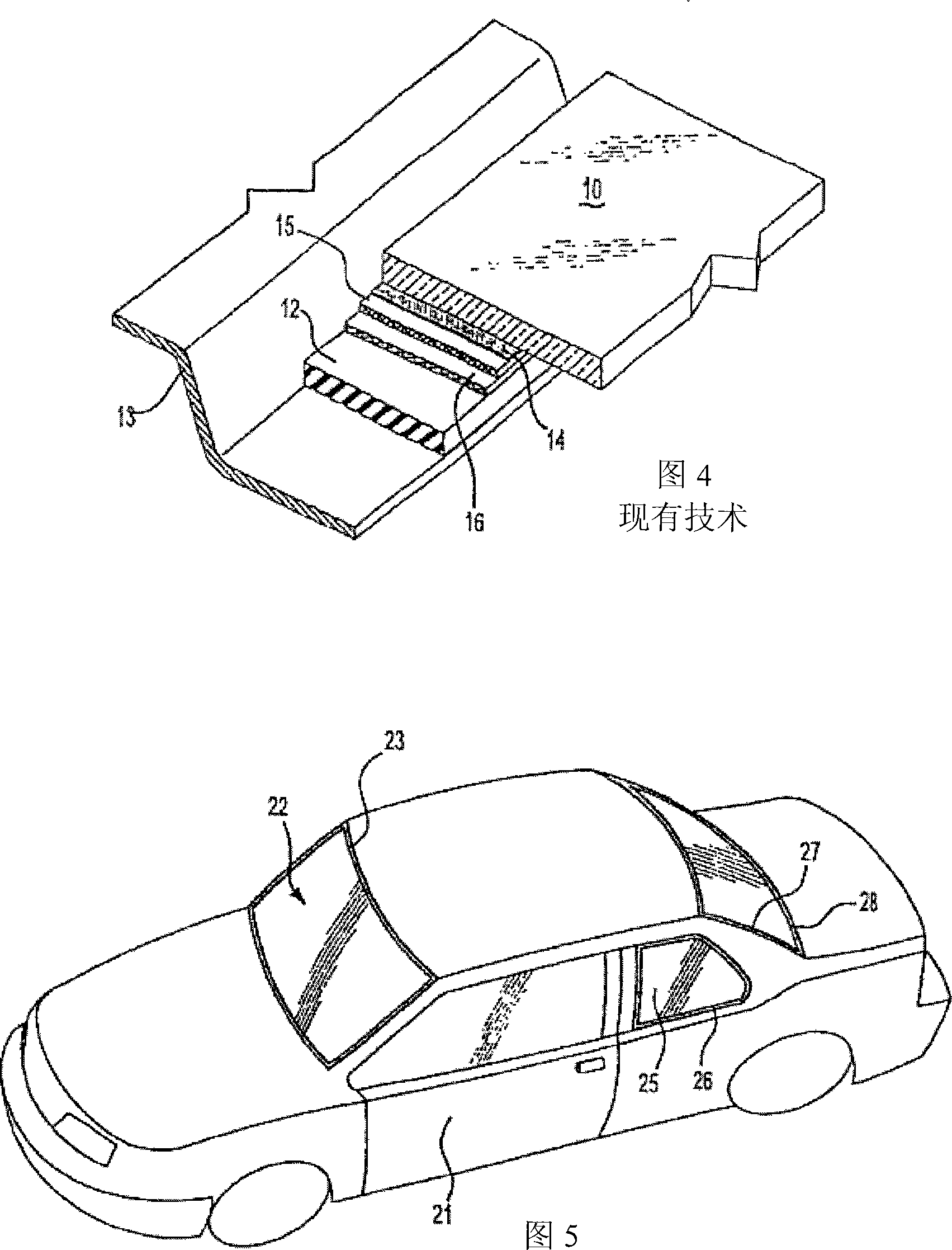

A coating and glass technology, applied to coatings, windshields, windows, etc., can solve problems such as difficult-to-recycle glass, and achieve low ultraviolet light transmittance and good opacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

[0106] Several formulated coating formulations of the present invention are described below.

[0107] The following ingredients were added to a Max 60 cup and mixed at speed for 30 minutes to ensure complete dissolution of the inhibitor and dispersant, and to wet out the pigment and filler with resin.

[0108] Table 1

[0109] Example

1 to 7

1 to 7

8

8

9

9

component

weight%

weight%

weight%

Acrylic Iso-ice

Tablet ester

24.600

16.400

11.480

16.4

11.165

15.950

Diacrylic acid three

Propylene Glycol Esters

12.225

8.150

5.705

8.150

5.705

8.150

Acrylic

8.940

5.960

4.172

5.960

4.172

5.960

Acrylation

Polysiloxane 1

0.600

0.400

0.280

0.400...

Embodiment 10

[0132] Use the following sequence of component additions: isobornyl acrylate (GENOMERTM 1121, Rahn); 12.70 g, Tripropylene glycol diacrylate (TRPGDA TM , UCB), 6.00 g, acrylic acid (from Acros Organics), 5.34 g, tetraethyl orthosilicate (SILBOND TM pure, SILBOND), 5.00 g, polyether-modified polydimethylsiloxane (BYK TM UV3510, BYK-Chemie), 0.36 g, polymerization inhibitor (ADDITIVE TM 01-468, Rahn), 0.50 g, polymeric dispersant (SOLSPERSE TM 32000, Avecia), 2.20 g, and aliphatic urethane acrylate oligomer (CN TM 985B88, Sartomer), 21.10 g. The components were added to a "Max 60 cup" from Flack Tek and mixed using a Hauschild Speed Mixer (DAC 150FVZ-K) at 1000 to 1500 revolutions per minute (RPM) for 4 minutes. This mixing process was repeated for an additional 4 minutes to ensure a homogeneous formulation. The homogeneous formula was then poured into an 8 oz (237 ml) plastic NALGENE TM bottle, then add 11.00 g of carbon black pigment (MOGUL TM E, Cabot) and 32.02 gra...

Embodiment 11-15

[0152] Add the listed ingredients to the Max 100 cup, speed mix for about 5 minutes to ensure complete dissolution of the inhibitor and dispersant, then add the carbon black to the Max 100 cup.

[0153] Table 6

[0154] component

gram

weight%

22.960

16.400

Tripropylene glycol diacrylate

11.410

8.150

Acrylic

8.344

5.960

Acrylated Polysiloxane 1

0.560

0.400

inhibitor 2

0.700

0.500

Dispersant 3

0.630

0.450

40.096

28.640

6.300

4.500

Alumina 6

49.000

35.000

sum

140.000

100.000

[0155] 1. TEGO RAD TM 2100

[0156] 2. ADDITIVE from Rahn TM 01-468 Inhibitor

[0157] 3. SOLSPERSE from Avecia TM 32000 dispersant

[0158] 4. CN from Sartomer TM 985B88

[0159] 5. MOGUL from Cabot ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com