An electric spindle design adopting air static pressure anti-thrusting and electromagnetism radical bearing support

A radial bearing and motorized spindle technology, applied in the mechanical field, can solve the problems that the motorized spindle cannot be lubricated by oil mist or oil and gas, the structural strength and conductivity of the aluminum alloy strip are low, and the PCB motorized spindle structure cannot be applied. The effect of compact structure, simple structure, and easy concentration of air supply pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

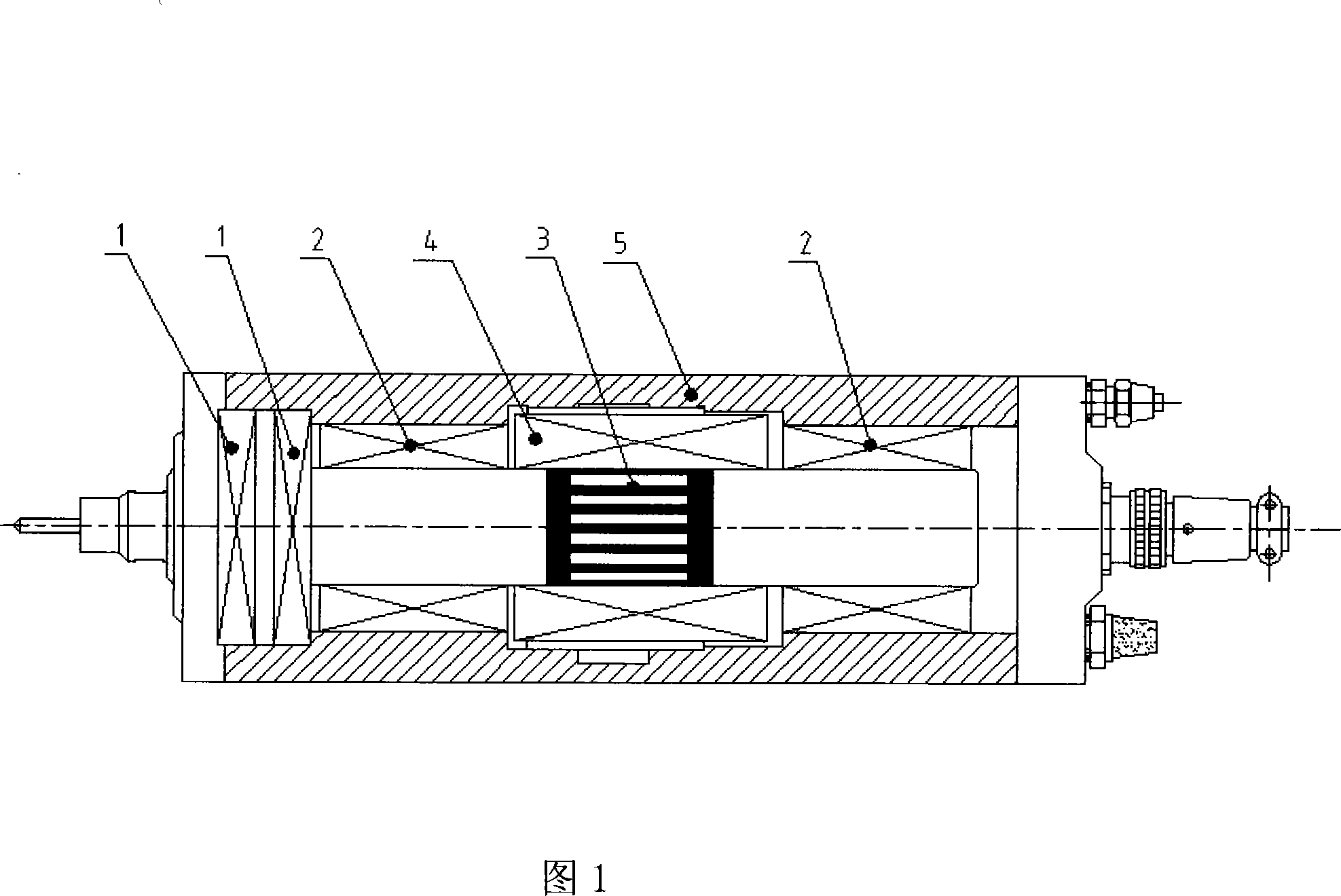

[0015] As shown in Figure 1, the design of the electric spindle adopting aerostatic pressure thrust and electromagnetic radial bearing support of the present invention, according to the external dimension limitation and rigidity requirements of the electric spindle, two A gas static pressure thrust bearing (1), centralized configuration can optimize the space utilization inside the electric spindle housing (5), make the overall structure of the electric spindle compact, and at the same time the air supply pipeline of the gas static pressure bearing (1) It is convenient for centralization and installation of the electric spindle, and provides the required axial stiffness for the rotor-shaft integrated shaft system (3); the stator (4) installed in the electric spindle housing (5) is symmetrically arranged with electromagnetic diameters on both sides The radial bearing (2) is used to support the rotor-rotating shaft integrated shafting (3). The symmetrically arranged electromagnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com