Heat pump drier

A technology of heat pump drying and drying chamber, which is used in heat pump, drying gas arrangement, drying and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

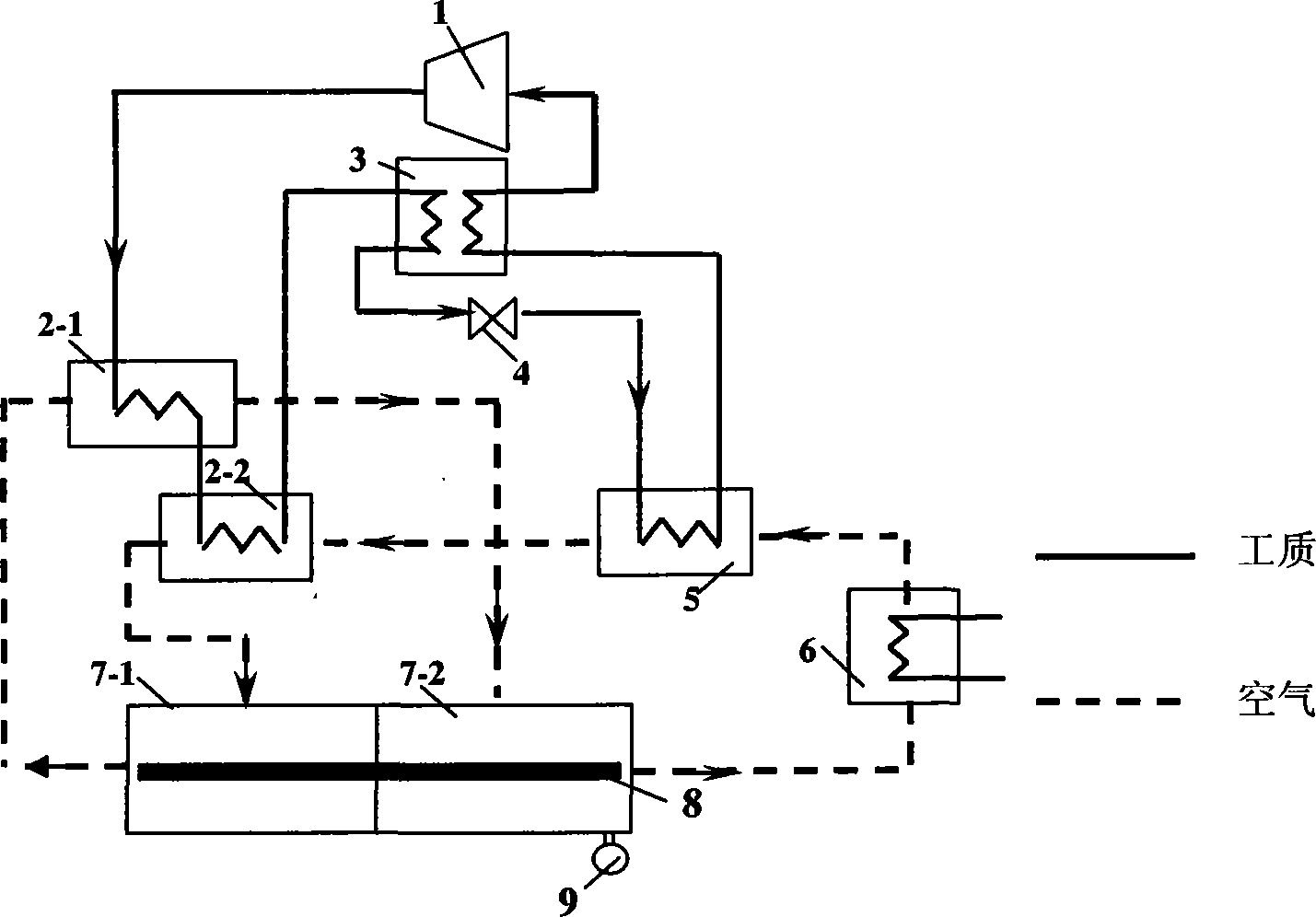

Image

Examples

Embodiment Construction

[0009] Below with Chinese cabbage seed drying as specific embodiment, content of the present invention is further described:

[0010] The dried material cabbage seeds are placed on the conveyor belt in the drying chamber. The initial moisture content of the cabbage seeds is 30%, and they are dried and dehydrated to a moisture content of 5%.

[0011] After compressor 1 is turned on, the CO 2 The working medium is compressed by the compressor 1 into a high-temperature and high-pressure working medium with a pressure of 9 MPa. After the temperature is 75°C, it enters the air source gas cooler 2-1 for the first cooling down to 45°C; at the same time, the temperature is 30°C and the humidity is 80%. The air is heated to a temperature of 45°C, the humidity drops to 35%, and the CO 2 After exchanging heat with the air, the working fluid enters the second air source gas cooler 2-2 for the second cooling down to 25°C. At the same time, the air with a temperature of 20°C and a humidity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com