Coal gas explosion-proof rapid purging device

A fast, gas-fired technology, applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve problems such as the inability to realize fast automatic purging, difficulty in ensuring safe production, etc., to achieve safe and fast automatic purging, prevent gas Back channeling, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

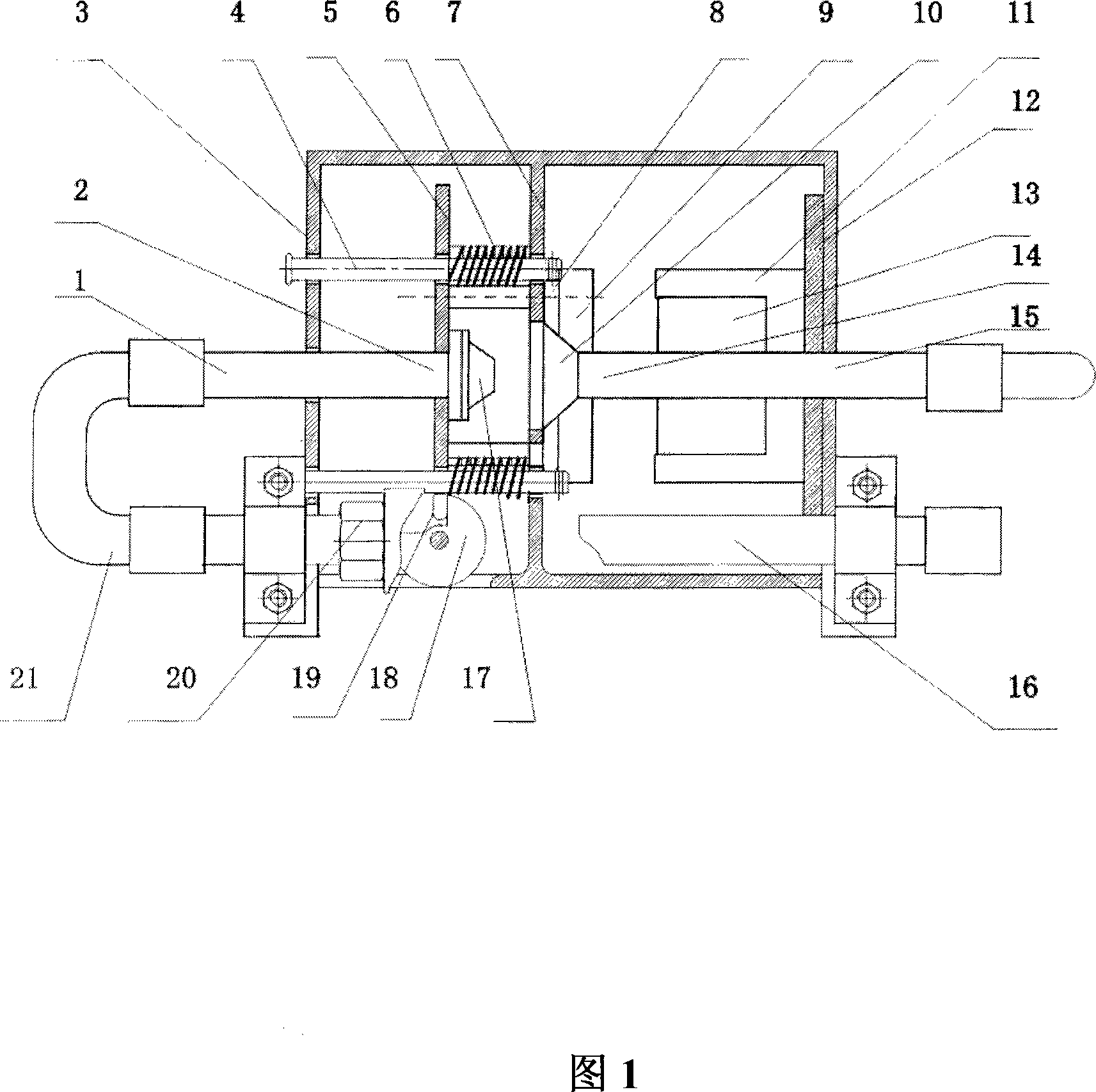

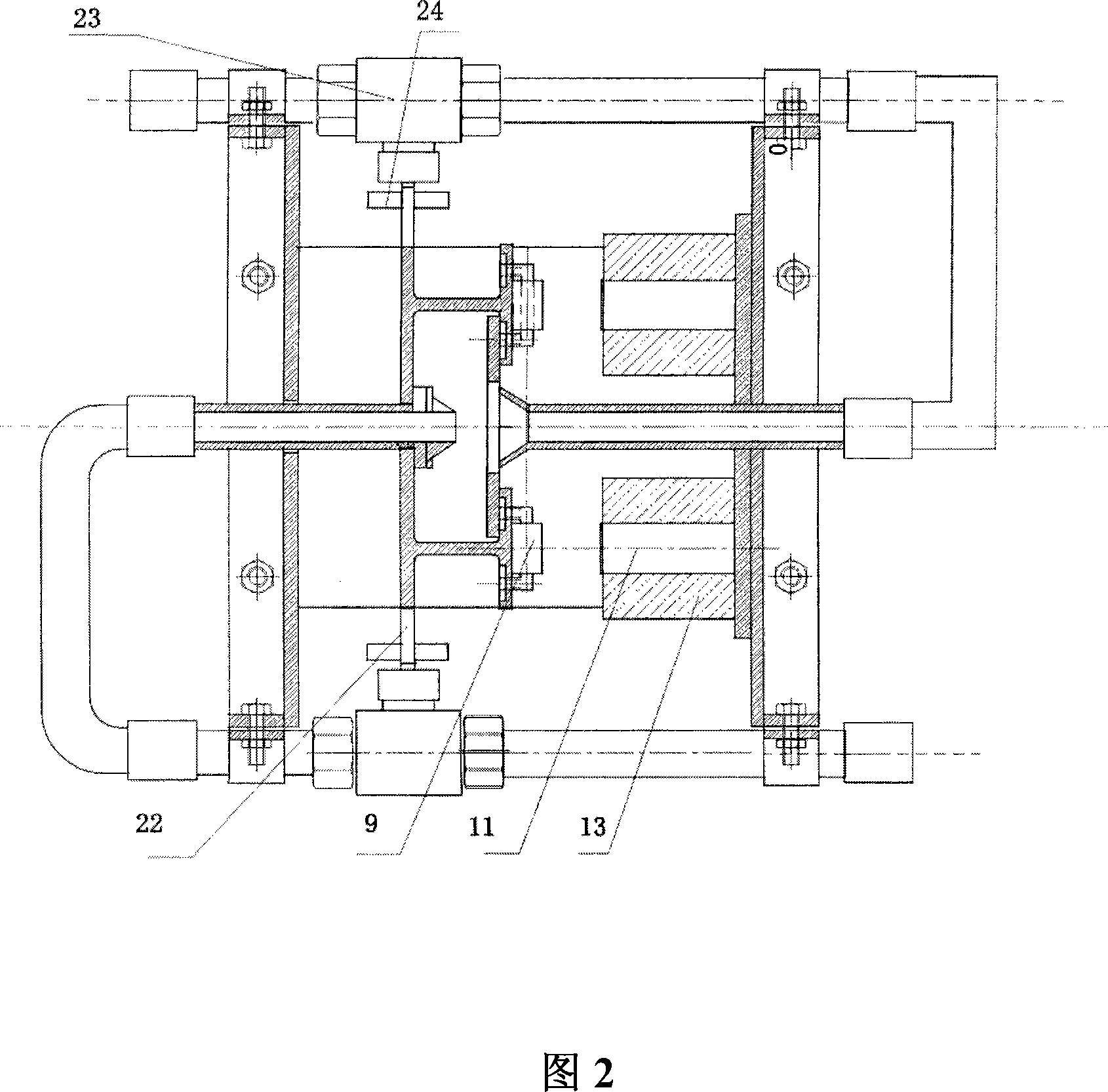

[0010] Such as figure 1 , 2 As shown, this gas explosion-proof quick purging device includes a housing 3 and a movable gas pipe 1 and a fixed air guide pipe 15 arranged outside the housing 3. The gas pipe 1 and the air guide pipe 15 are respectively provided with a gas ball valve 20 and a gas guide pipe 15. The gas ball valve 23, the other end of the gas ball valve 20 is connected to the fire extinguishing gas pipe 16, nitrogen gas is inserted into the fire extinguishing gas pipe 16, and the other end of the gas ball valve 23 is connected to the gas pipeline, and a partition plate 7 is mainly fixed in the housing 3 And the air-guiding dynamic interface mechanism 2 and the air-guiding static interface mechanism 14 and the ball valve control mechanism 19 linked with it are arranged on both sides of the partition plate 7; , moving magnet 9, the moving magnet 9 is connected to the partition plate 7 through the fixed plate 8, the sliding guide rod 4 with the return spring 6 is set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com