Detachable pipe joint

A technology for connectors and pipes, applied in the direction of pipes/pipe joints/fittings, flange connections, sleeve/socket connections, etc., can solve problems such as reduced production efficiency, difficult operation, and reduced work efficiency, so as to save production costs, Improved durability and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

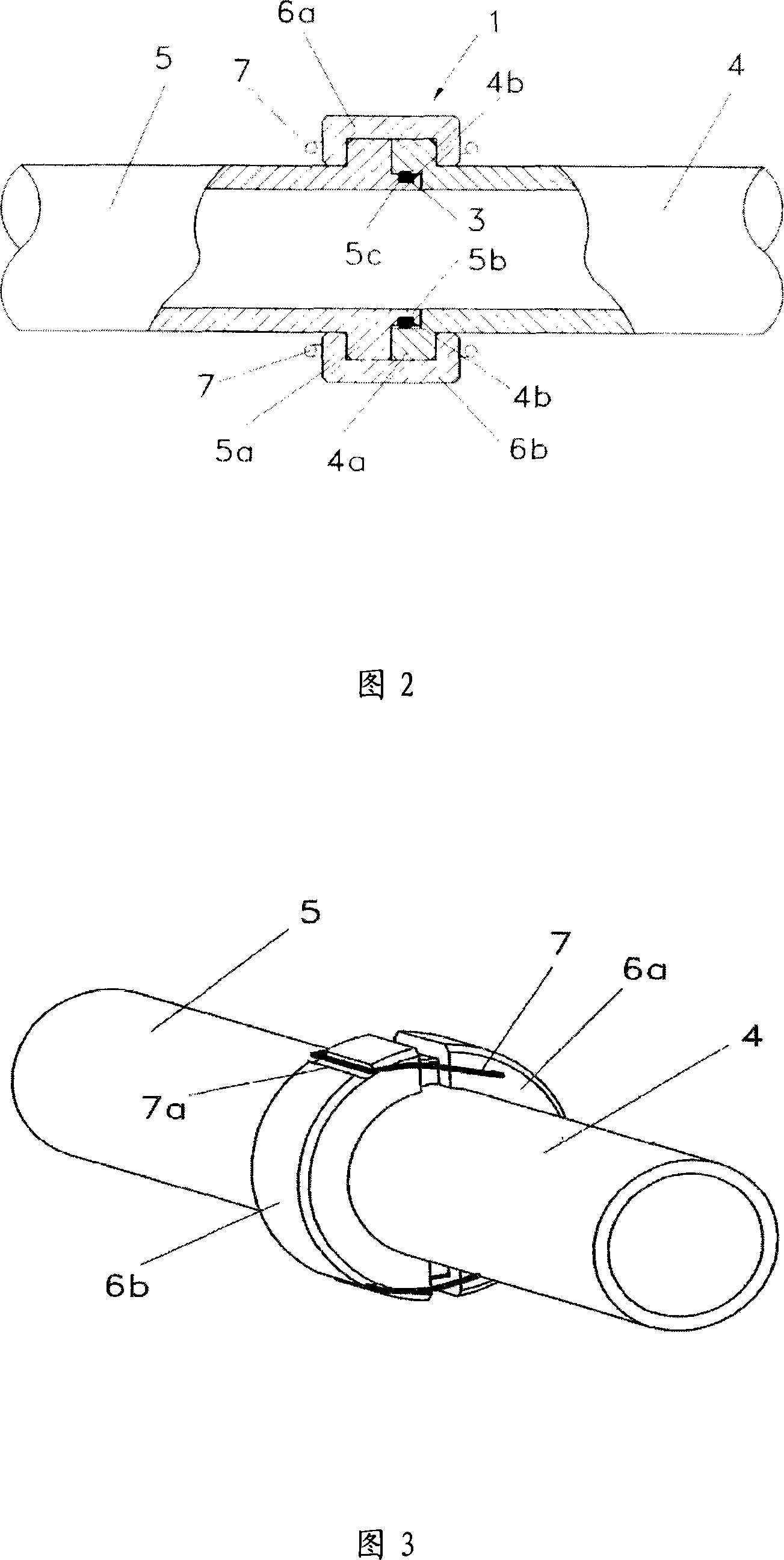

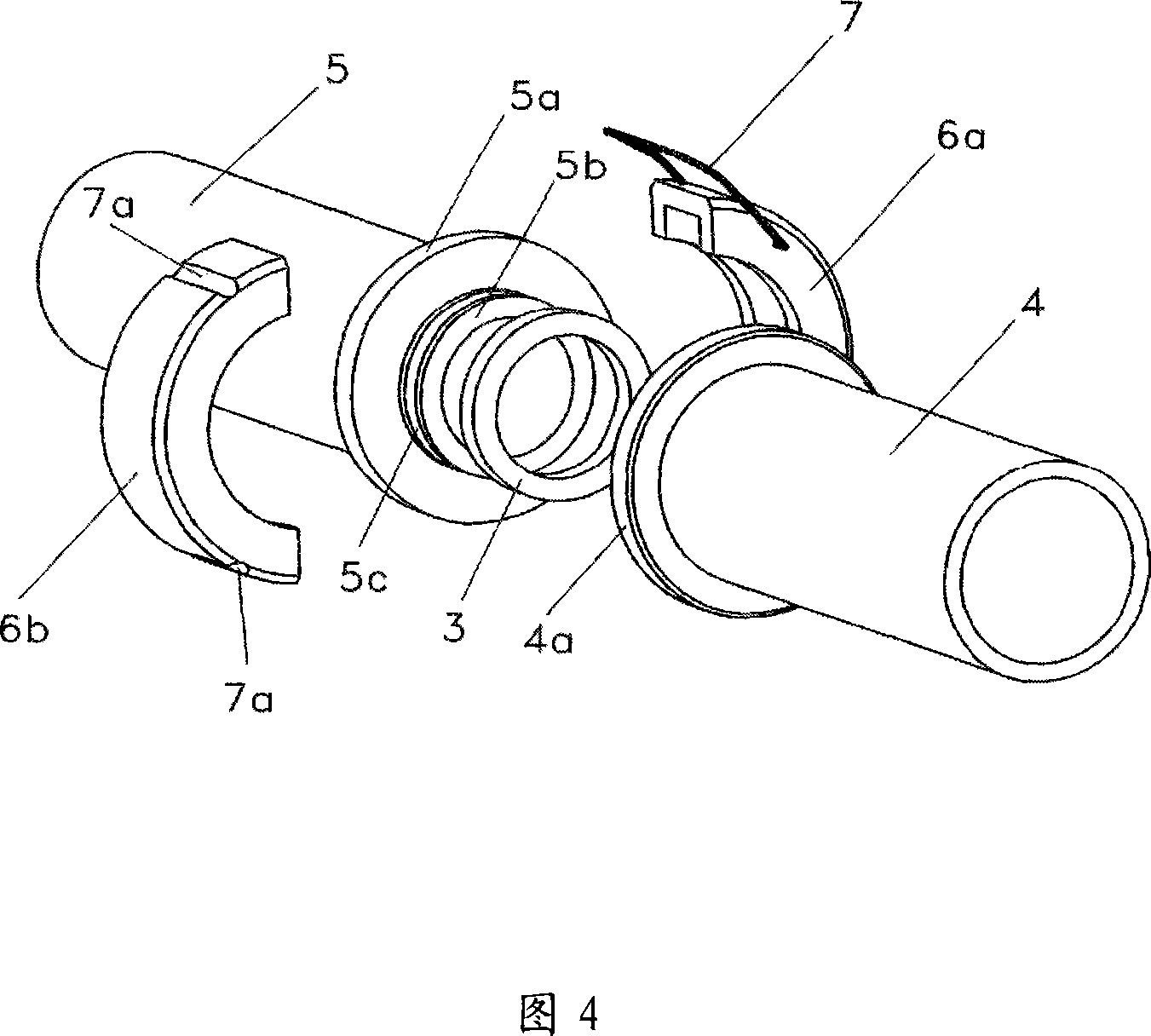

[0015] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

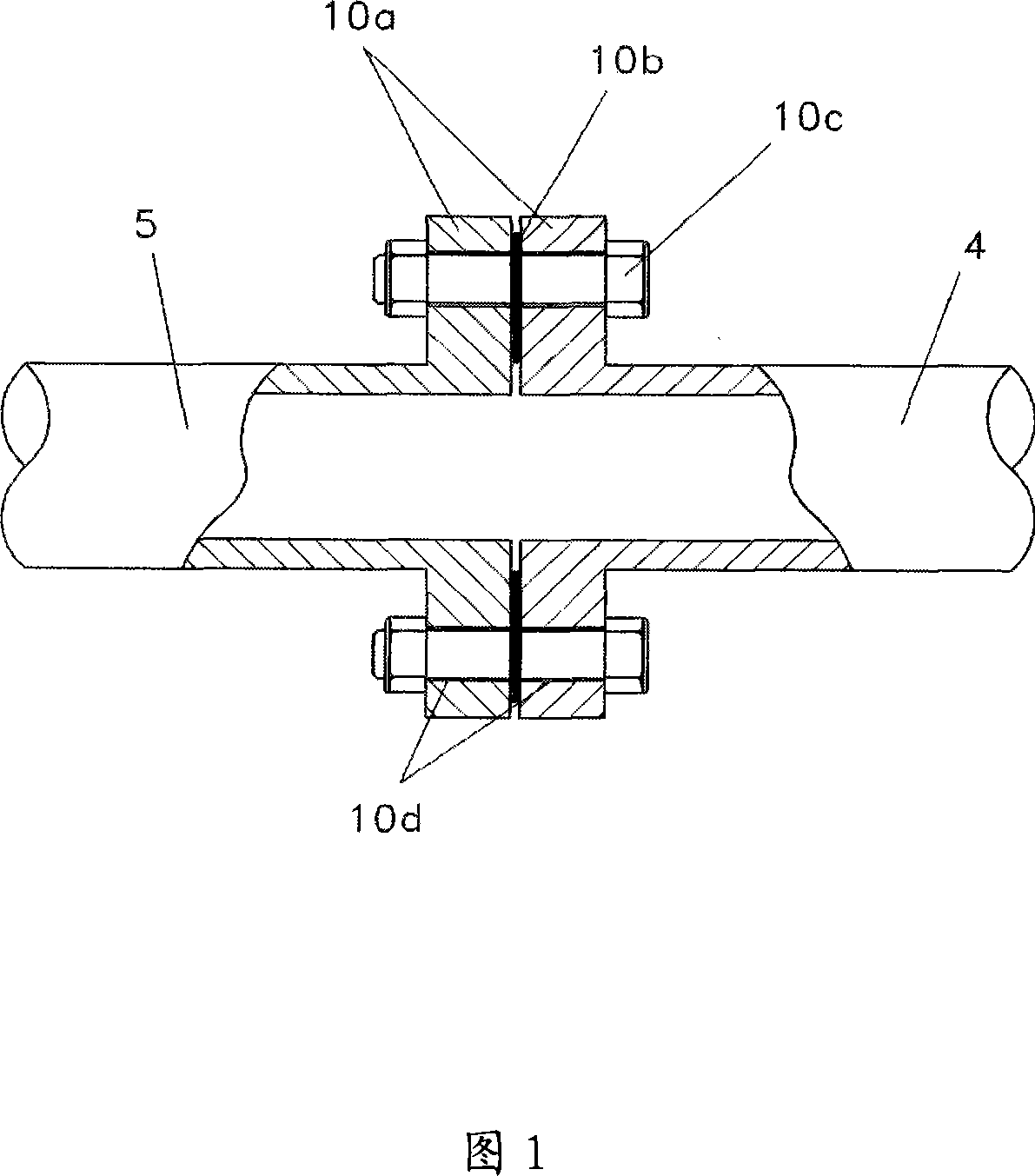

[0016] Figure 1 illustrates the existing flange connection method. For the connection of medium and large connecting pipes 4 and 5, it is difficult to use tapered bolts for processing. flanges 10a, and machine a plurality of bolt holes 10b on the flanges, and insert gaskets 10b between the flanges 10a for the sealing connection, and then use a plurality of bolts 10c to bond and fix.

[0017] The above-mentioned connection method needs to tighten a plurality of bolts 10c, thus requiring a long working time, and the bolts 10c are likely to be worn or broken during the process. And a wider flange 10a is required to use the bolt 10c, which increases the material weight, and also requires machining a plurality of bolt holes, thereby increasing the production unit price.

[0018] The connection method of the present invention does not need to tighten the bolt 10c. As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com