Method and device for controlling wafer DC auto-bias and compensating electrostatic gravitational force between direct current electrode and water

A technology of DC electrodes and electrostatic attraction, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve problems such as inaccuracy, signal loss changes, and cannot be determined or estimated in advance, so as to improve process results and reduce Effect of Small Helium Leak Rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

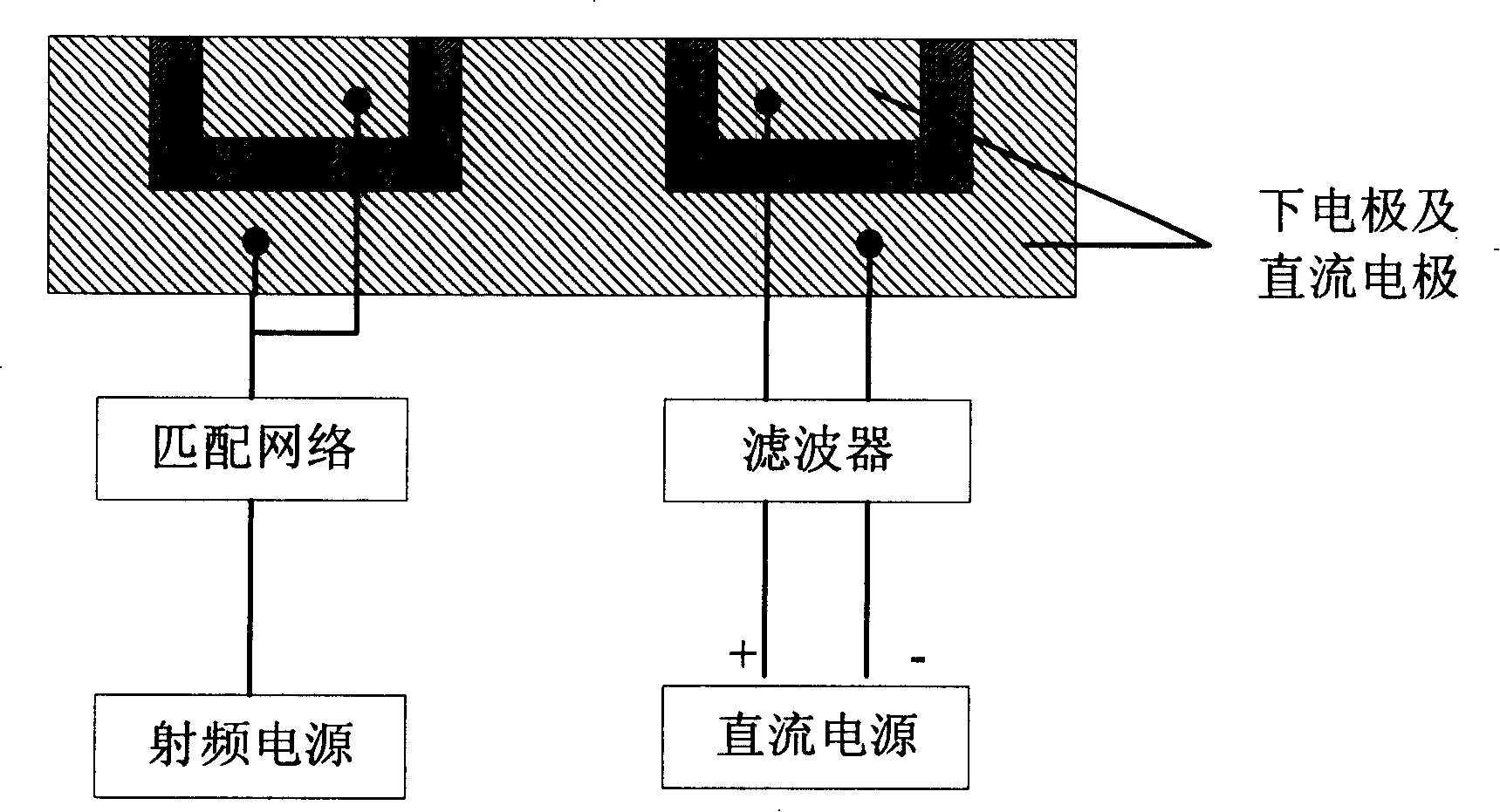

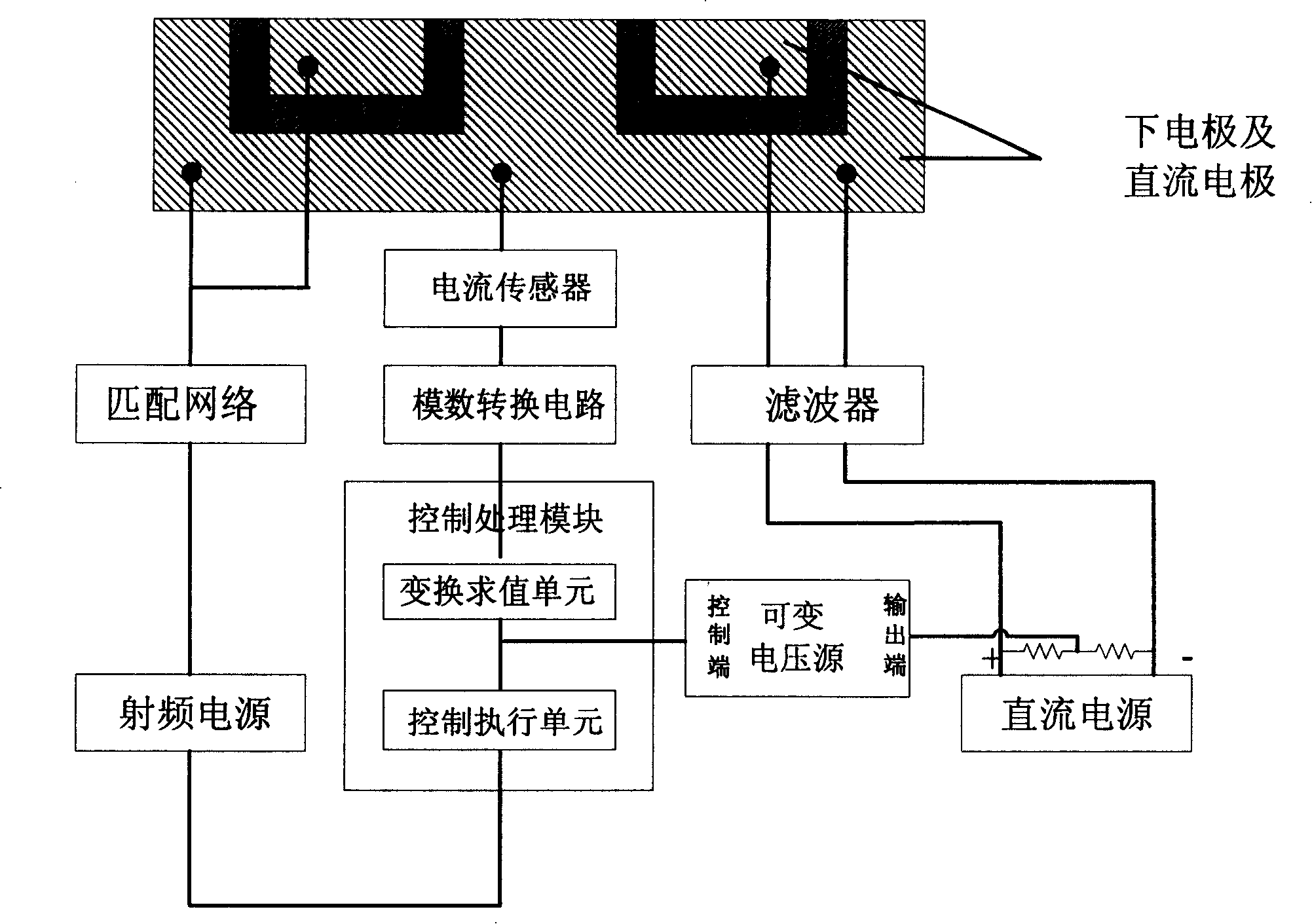

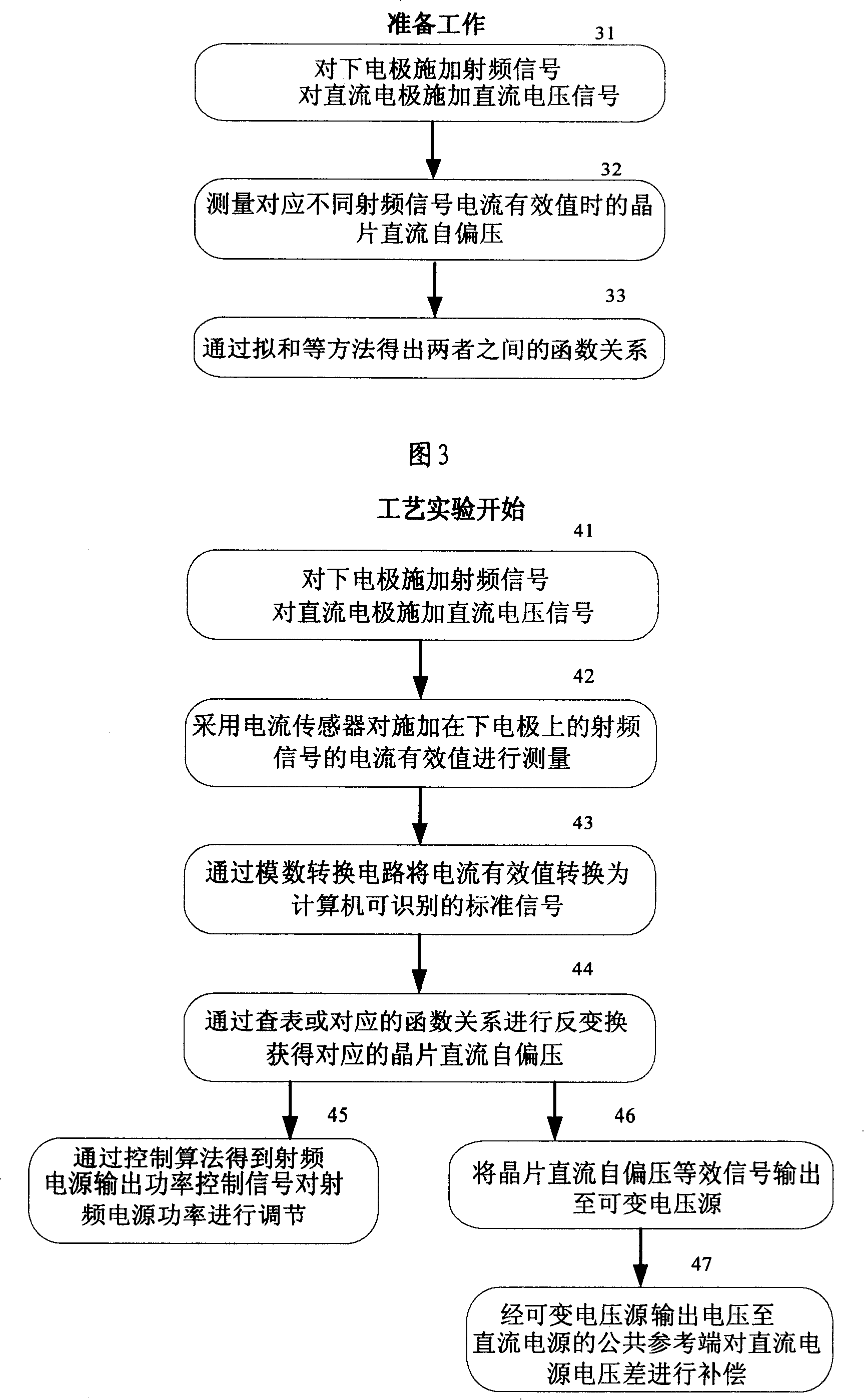

[0056] The present invention controls and compensates the DC self-bias voltage of the wafer by constructing a closed-loop feedback system, that is, indirectly obtains the value of the DC self-bias voltage by measuring a parameter that can characterize the magnitude of the DC self-bias voltage of the wafer, and then controls or compensates the value of the DC self-bias voltage The conversion links are respectively used to control the common reference terminals of the radio frequency power supply and the DC power supply. These include:

[0057] 1. The implementation method of controlling the DC self-bias voltage of the chip, including:

[0058] Measure a parameter that can characterize the DC self-bias voltage of the chip to indirectly obtain the value of the DC self-bias voltage, and then output the control signal after the value is compared and controlled to control the output power of the RF power supply, and then realize the control of the chip. DC self-bias control. in: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com