Thermo-acoustic heat engine acoustic field monitoring method monitoring system

A thermoacoustic system and monitoring system technology, applied in the testing of machines/structural components, measuring ultrasonic/sonic/infrasonic waves, measuring devices, etc., can solve the problem of adding measuring points, the influence of the sound field of the measured system, and limiting the pressure and sealing of the system Performance and other issues, to achieve the effect of reducing influence, simple measurement procedure and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

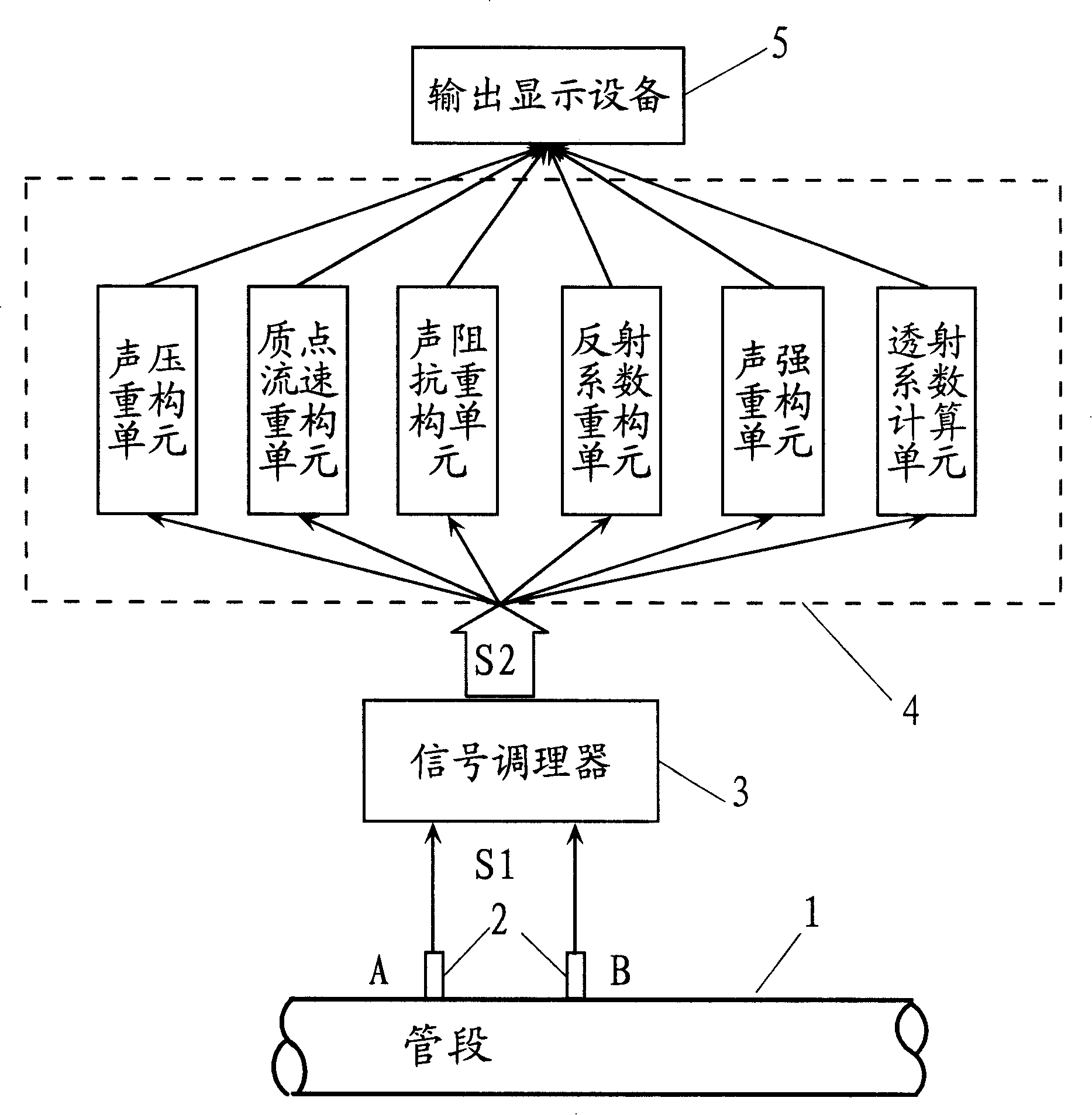

[0049] According to the present invention, refer to figure 1 , two sound pressure sensors 2, respectively denoted by A and B here, are arranged at the sound pressure measuring holes on the pipe wall of the pipe section 1 of the thermoacoustic device. Keep it flat and ensure the sealing of the system from the outside world, so as to minimize the disturbance caused by the measurement system to the sound field.

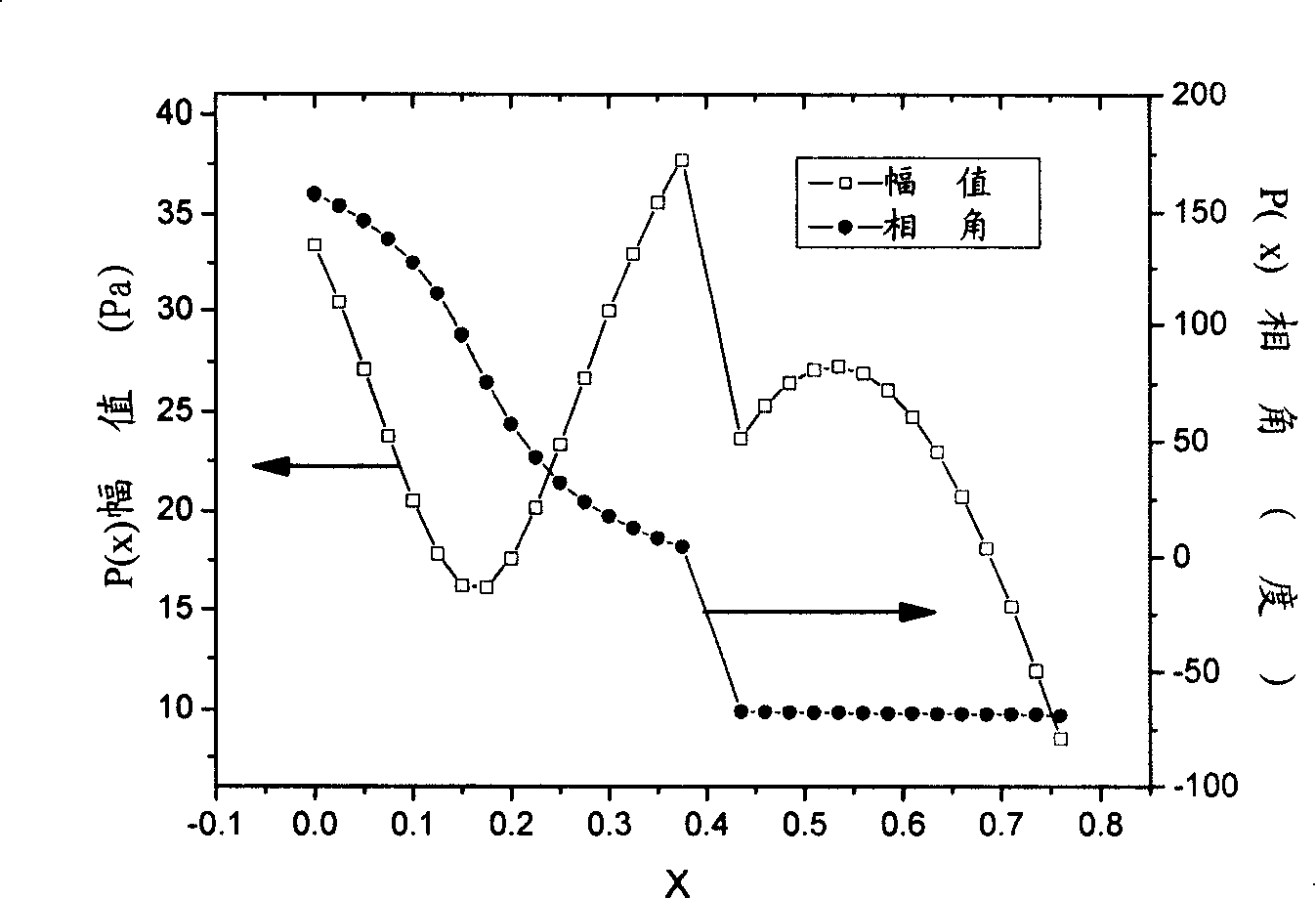

[0050] The acoustic pressure sensor 2 converts the oscillating pressure of the fluid working medium at its location into a corresponding electrical signal S1. The electrical signal S1 representing the sound pressure from the sound pressure sensor 2 enters the signal conditioner 3 to amplify or reduce the intensity. The conditioned electrical signal S2 representing the sound pressure enters the signal processing device 4 . It should be pointed out that the signal processing device can be composed of a computer with AD conversion function, but various other types of sign...

Embodiment 2

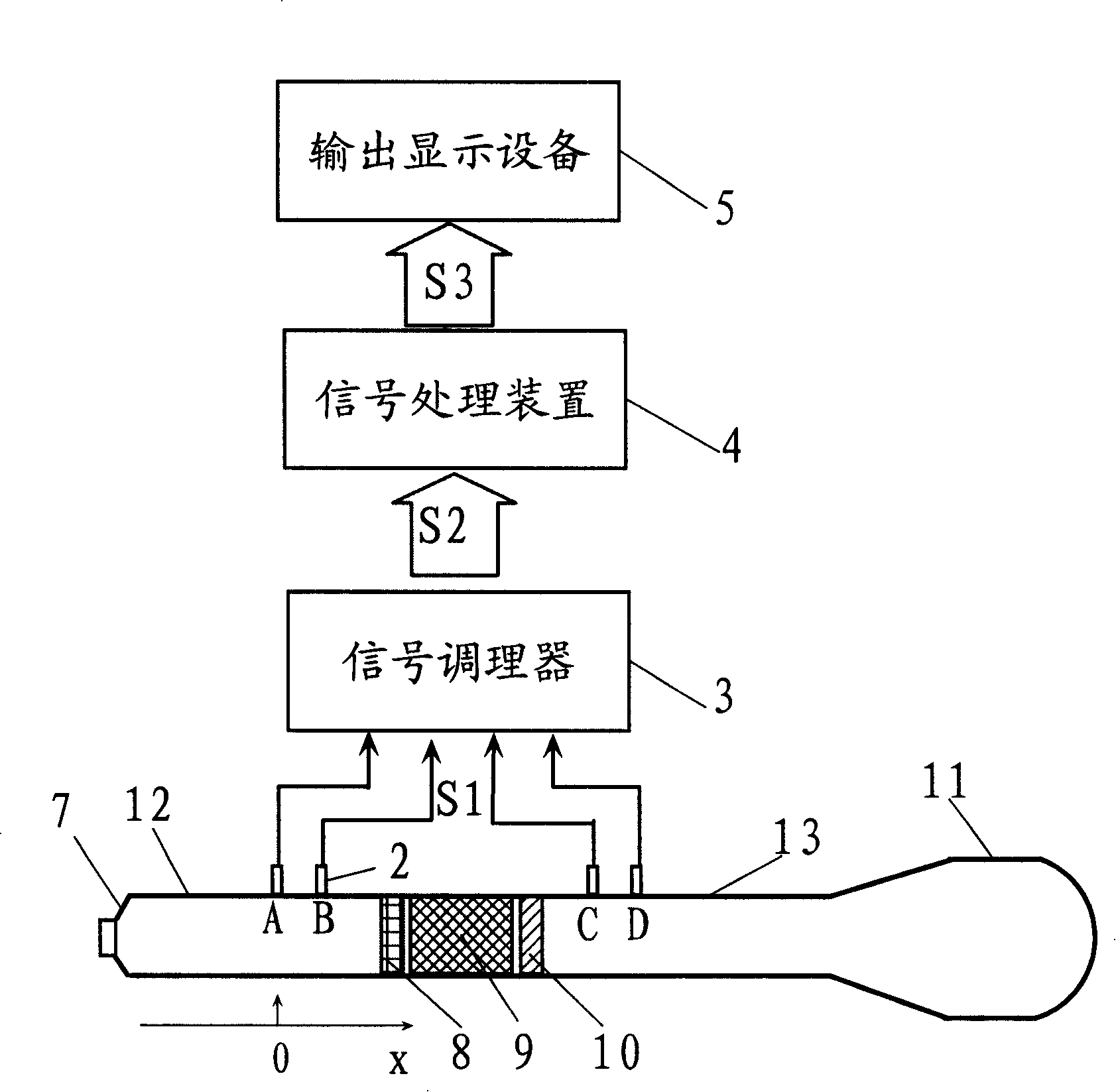

[0080] Figure 8 Another embodiment of the invention is shown, namely its implementation in a standing wave thermoacoustic engine. The standing wave thermoacoustic engine is composed of pipe sections 14 and 15, a hot-end heat exchanger 8 (also called a heater), a regenerator 9, and a cold-end heat exchanger 10 (also called a cooler) and the like. The difference between it and the refrigerating machine in Embodiment 1 is that the refrigerating machine generates cooling effect through the sound work input from the outside (speaker), while the thermoacoustic engine is responsible for generating self-excited oscillation by applying a temperature gradient at both ends of the regenerator , output sound power.

[0081] Although the structure and working principle of the thermoacoustic engine and the refrigerator described in Embodiment 1 are different, the rules followed by the sound field in the resonant cavity of the two are exactly the same, so the sound field reconstruction meth...

Embodiment 3

[0083] Figure 9 Still another embodiment of the invention is shown, namely its implementation in a Stirling-type traveling wave thermoacoustic engine. The Stirling-type traveling-wave thermoacoustic engine has a more complex structure than the standing-wave thermoacoustic engine. Its resonant cavity is composed of two parts: an annular ring and a side branch. A hot-end heat exchanger 8 , a regenerator 9 and a cold-end heat exchanger 10 are arranged in the annular ring, and the resonant tube 18 and the cavity 19 are connected with the annular ring through a joint 20 . The hot end heat exchanger 8, the regenerator 9, the cold end heat exchanger 10 and the joint 20 divide the annular ring into two parts, and the part from the cold end heat exchanger 10 to the joint 20 becomes a feedback pipe, and from the joint 20 to the The part of the heat exchanger on the hot side is called the thermal buffer tube.

[0084] Such as Figure 9 As shown, a pair of pressure measuring holes are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com