Preparation of carbon nano-tube array

A carbon nanotube array and carbon source gas technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve problems such as complex equipment, poor laser beam focus, and inability to accurately control laser beam movement. The method is simple and reliable control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

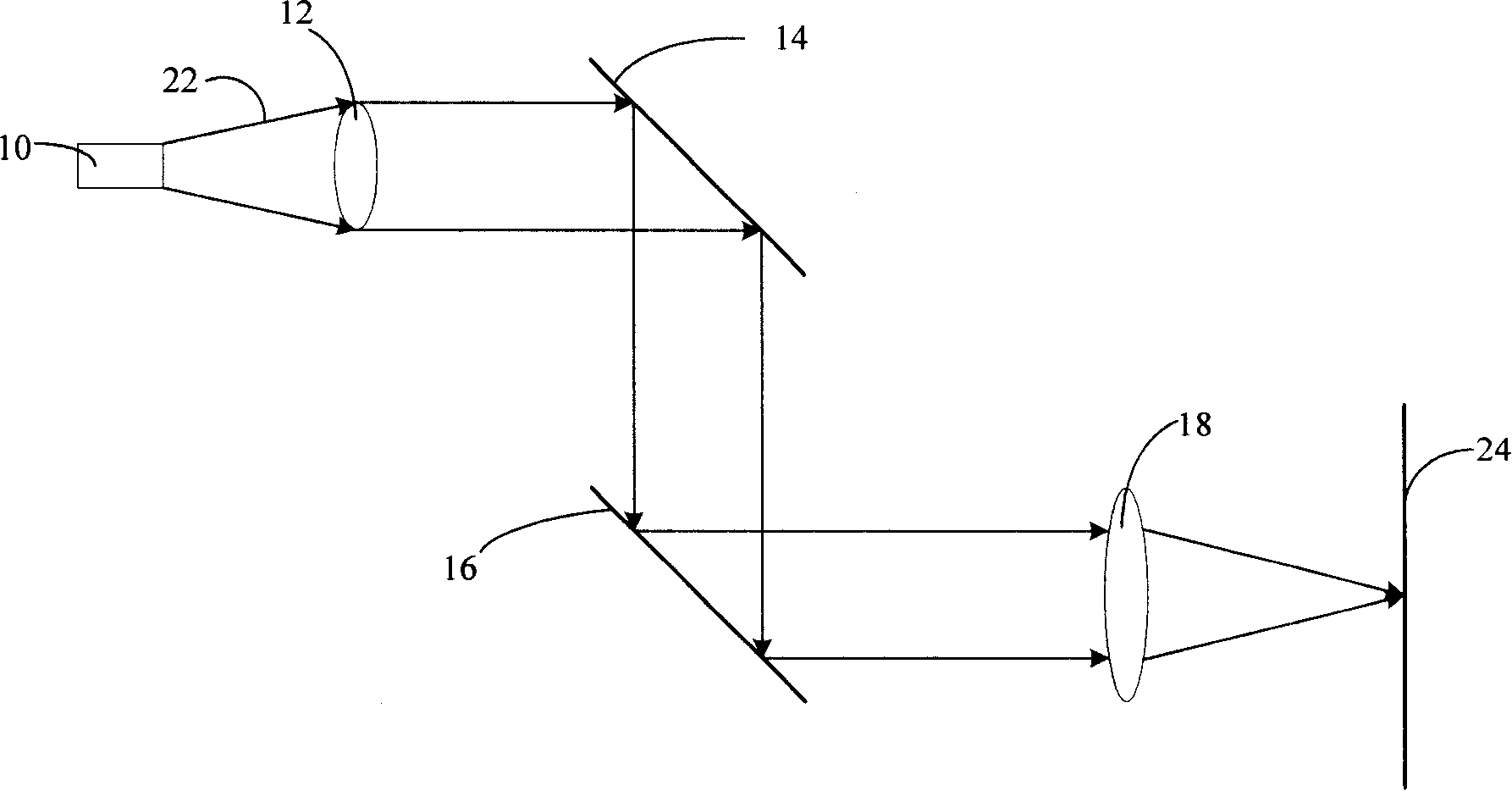

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings.

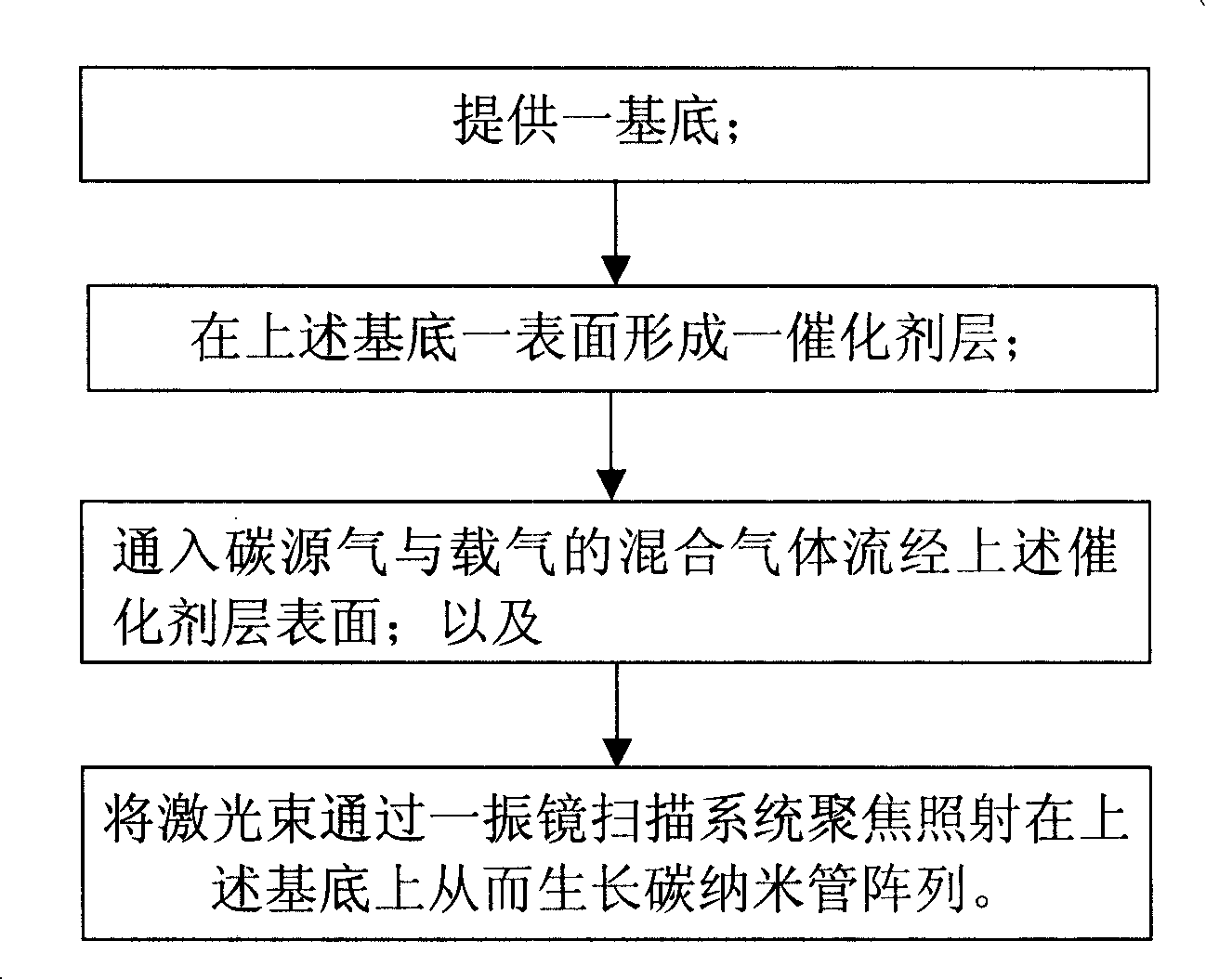

[0015] see figure 1 , the preparation method of the carbon nanotube array in the embodiment of the present invention mainly includes the following steps:

[0016] Step 1: Provide a base.

[0017] In this embodiment, the base material is made of high temperature resistant material. Preferably, the substrate material in this embodiment can also be opaque materials such as silicon, silicon dioxide or metal materials, or transparent materials such as glass and plastic organic materials.

[0018] Step 2: uniformly forming a catalyst layer on a surface of the substrate.

[0019] Formation of the catalyst layer can be accomplished by thermal deposition, electron beam deposition or sputtering. The catalyst layer is made of iron, or other materials, such as gallium nitride, cobalt, nickel and alloy materials thereof. Further, the catalyst layer can be oxidized by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| rotating speed | aaaaa | aaaaa |

| rotating speed | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com