Mounting structure for resin mudguard

A technology for installing a structure and a fender, which is applied in the directions of the superstructure, the sub-assembly of the superstructure, transportation and packaging, etc., can solve the problems of difficulty in adopting the fender installation structure, reduced workability, and difficulty in installing the fender.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

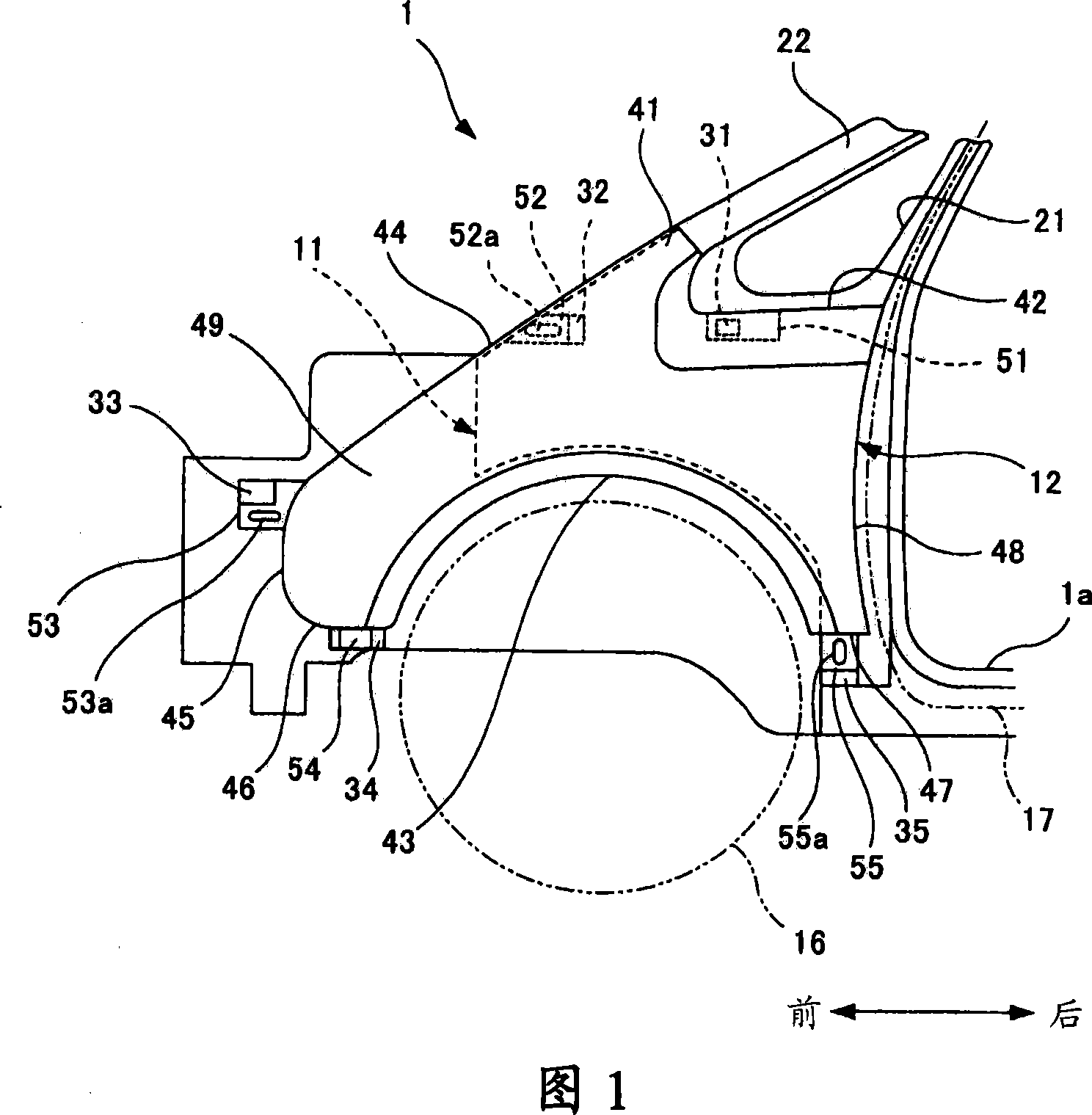

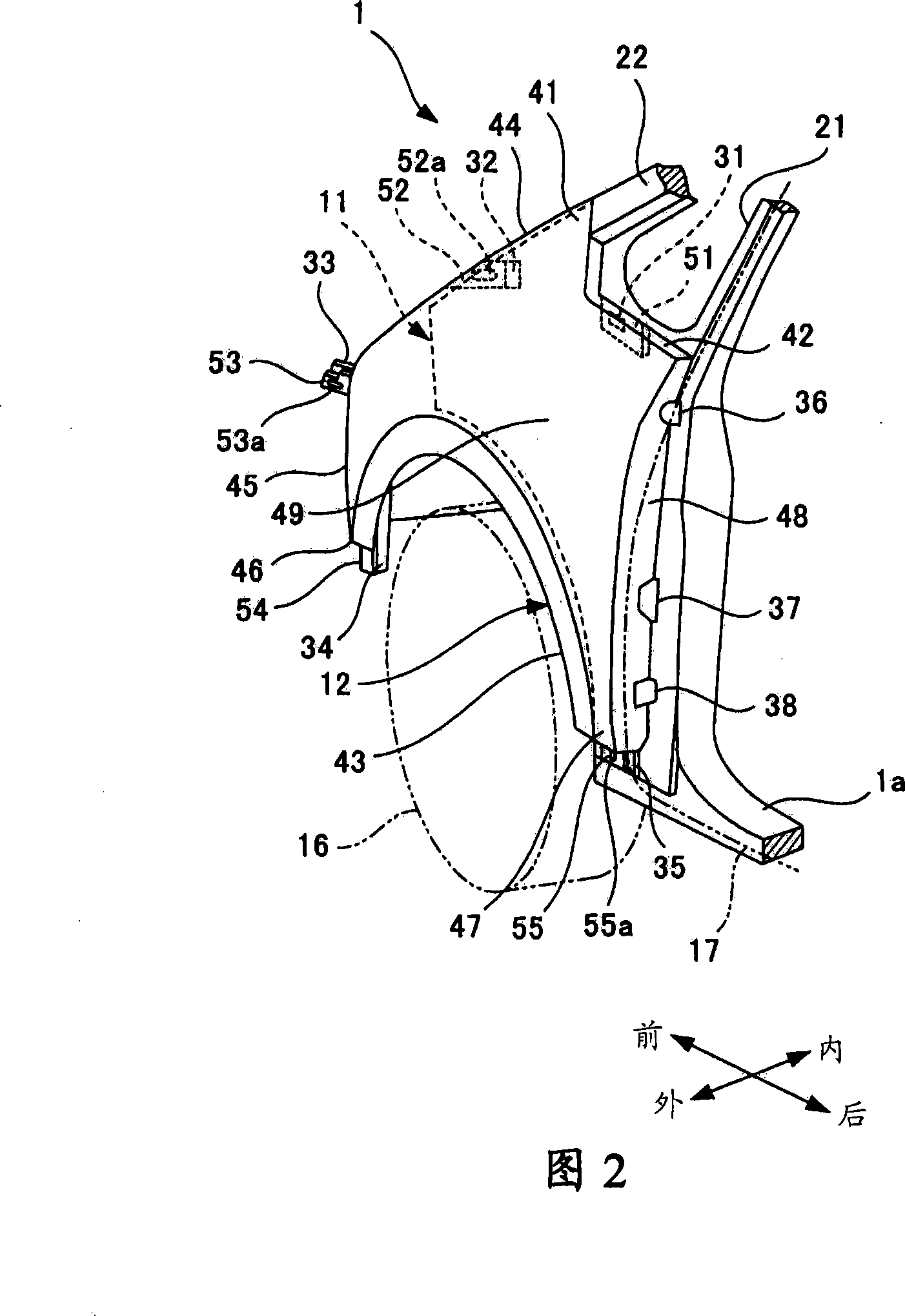

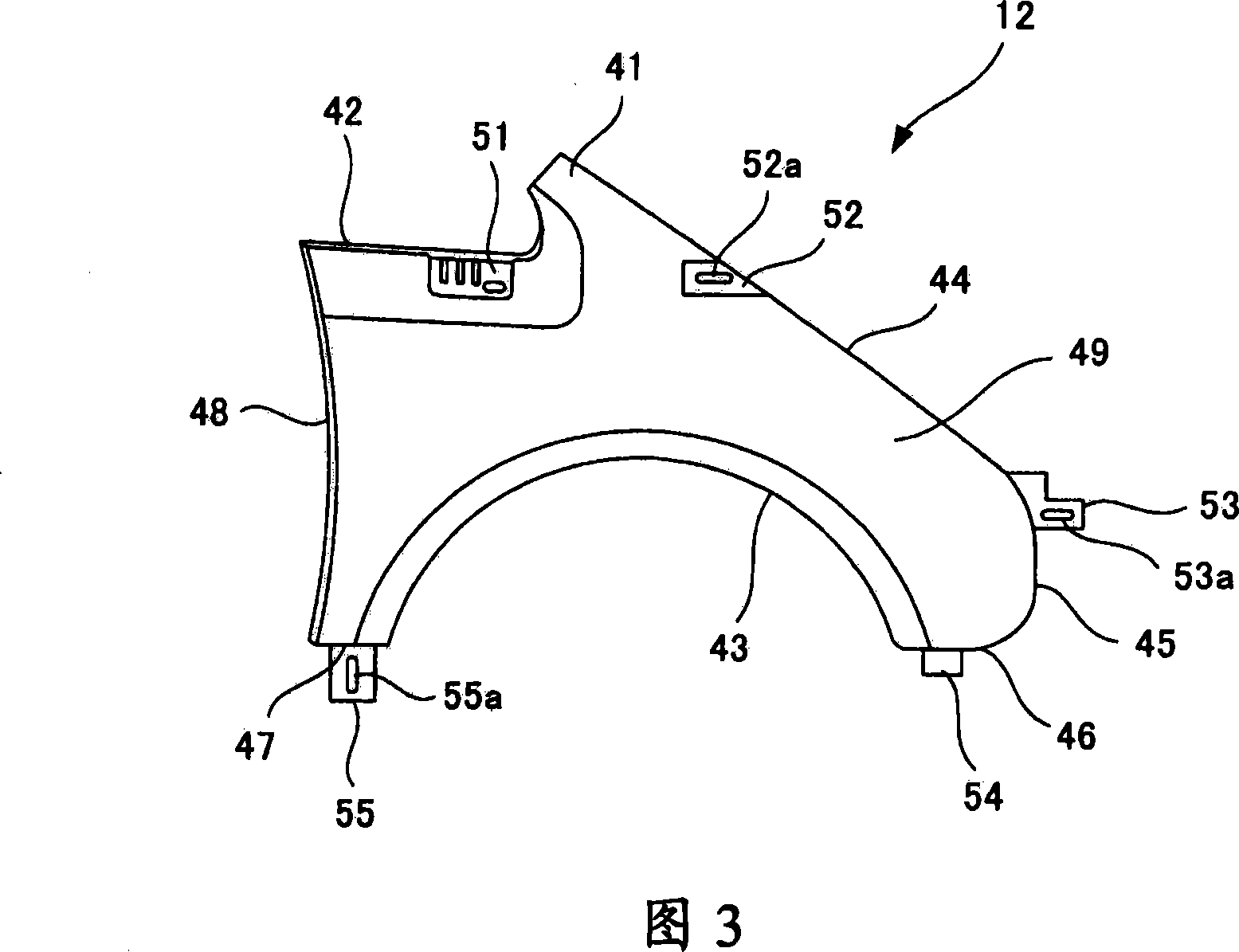

[0032] Hereinafter, a resin fender attachment structure according to an embodiment of the present invention will be described in detail with reference to the drawings.

[0033] As shown in FIGS. 1 to 3 , wheels 16 are rotatably supported in the vehicle body body 1 . Above the wheels 16 , an outer panel 11 is attached to a side surface of the vehicle body 1 , and a fender 12 made of resin is provided on the outer surface of the outer panel 11 . A door opening 1 a is formed behind a fender 12 of the vehicle body 1 , and a door 17 is attached to the vehicle body 1 so as to be able to open and close the door opening 1 a.

[0034] Formed on the upper portion of the outer panel 11 are: a triangular opening 21 opening in a triangular shape; and a front pillar 22 forming a front frame of the triangular opening 21 and extending obliquely rearward and upward. A triangular glass 13 having a triangular shape is provided outside the triangular opening 21 , and the edge of the triangular g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com