Used sand reclamation method and used sand reclamation thereof

A technology for regenerating old sand and regenerating sand, applied in the field of old sand recycling equipment, can solve the problems of secondary pollution of the environment, difficult to reuse, etc., and achieve the effect of strong inert membrane capability, high quality and water saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

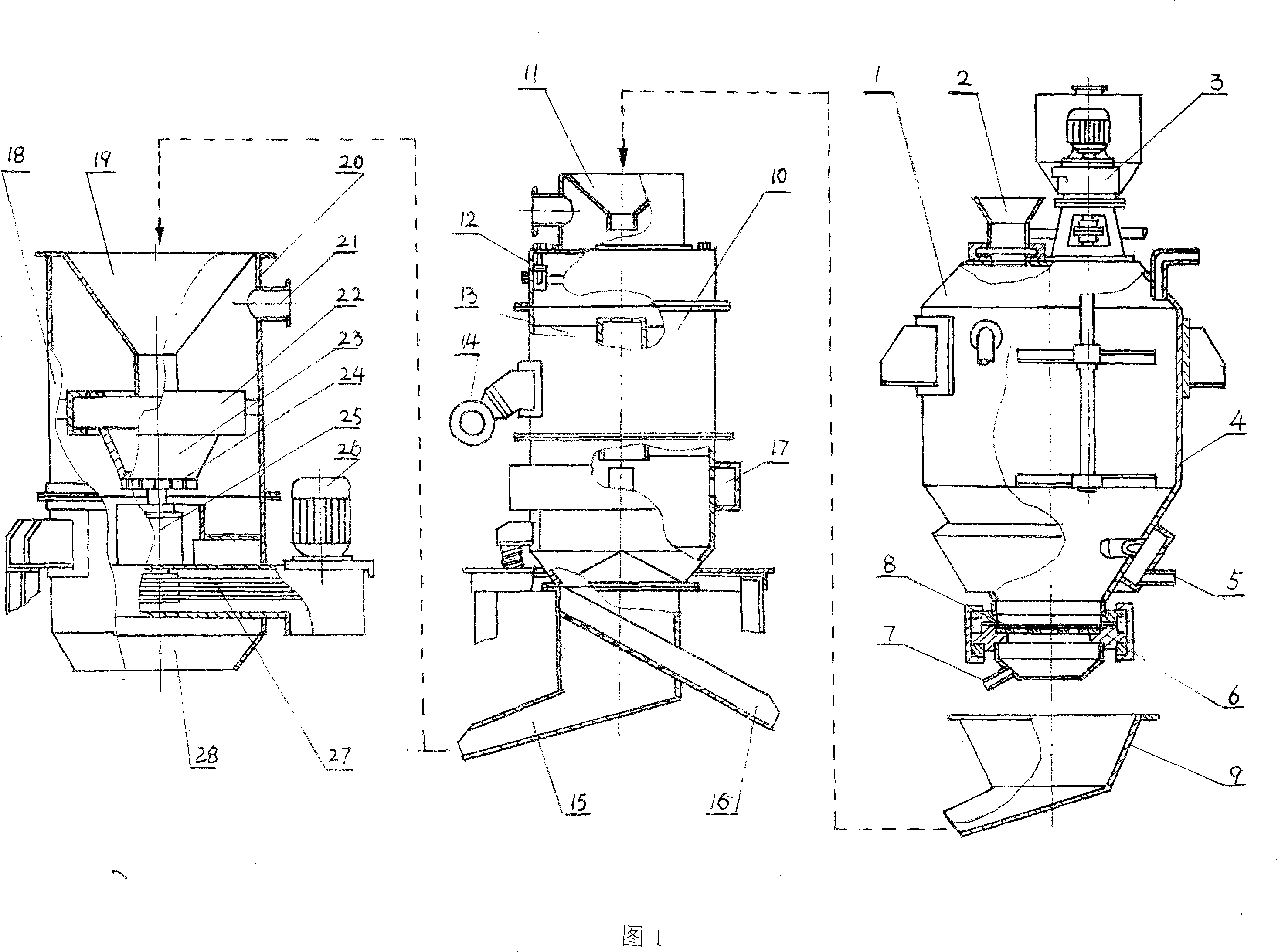

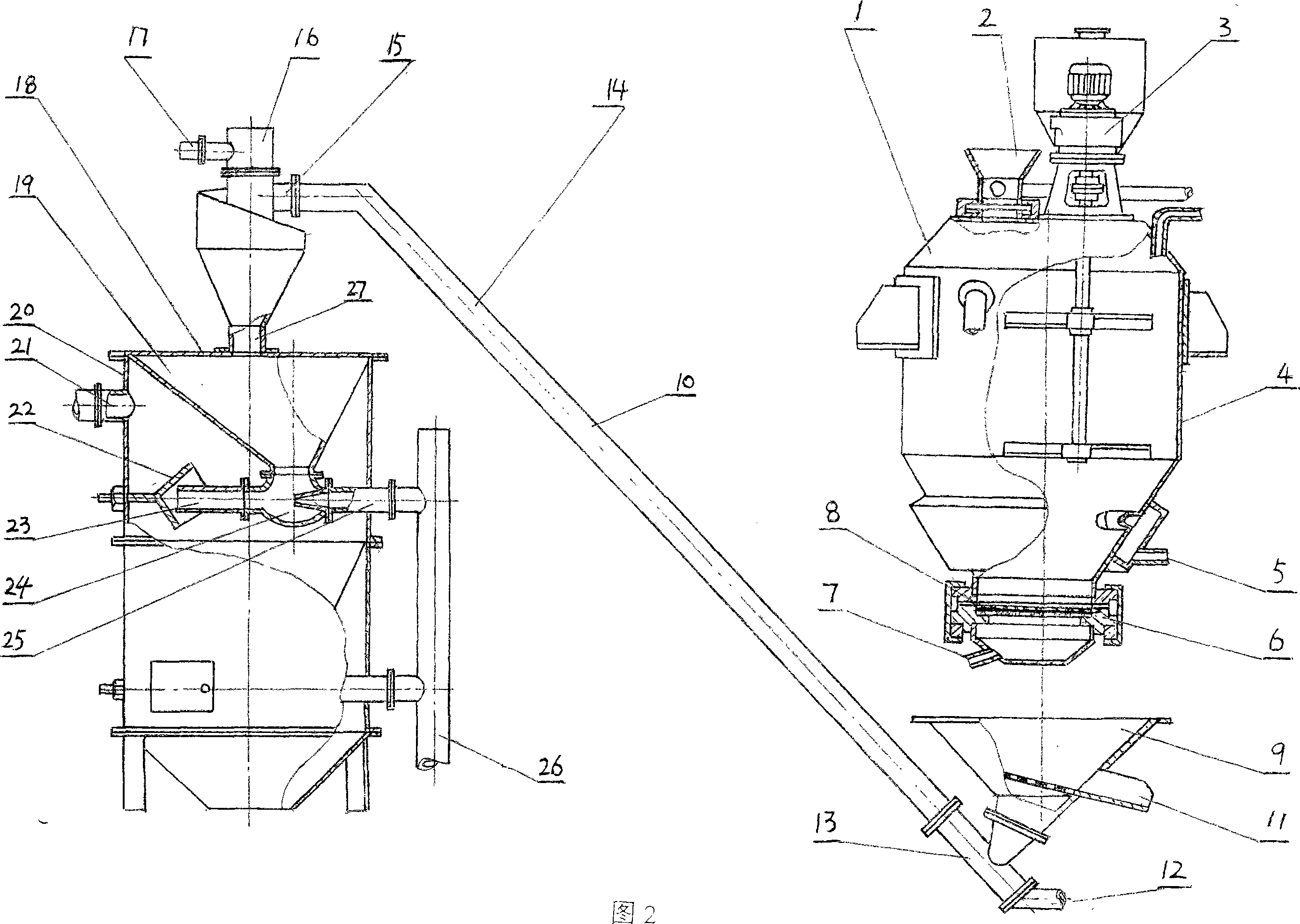

[0024] FIG. 1 shows that the old sand regeneration system includes a heat flow regeneration machine 1 , an intermediate sand bucket 9 , a dryer 10 , and a centrifugal regeneration machine 18 . The heat flow recycler 1 is a vertical device, including a sand inlet hopper 2, a stirring device 3, a bucket body 4, a heat inlet pipe 5, a sand discharge port sealing bottom plate 6, a metal mesh 8, and a drain pipe 7. The staving 4 is installed on the frame (not shown in the figure), and the sand-advancing bucket 2 is located on the top of the staving 4, and the stirring device 3 is installed on the top of the staving 4 by a bearing seat, and its impeller is in the staving inside. The heat inlet pipe 5 is located at the bottom of the staving 4 and communicates with the staving. The heat inlet pipe 5 is also communicated with the boiler (not shown in the figure) simultaneously. The bottom of staving body 4 is provided with sand discharge port sealing base plate 6, and base plate can o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com