Method for rolling tube by hot-rolled seamless tube restraint core rod continuous rolling mill

A technology for restricting mandrels and seamless steel pipes, applied in metal rolling, metal rolling, rolls, etc., can solve the problems of difficult deformation of stainless steel, inability to separate from the mandrel, and holes on the surface, reaching a wide range of applications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

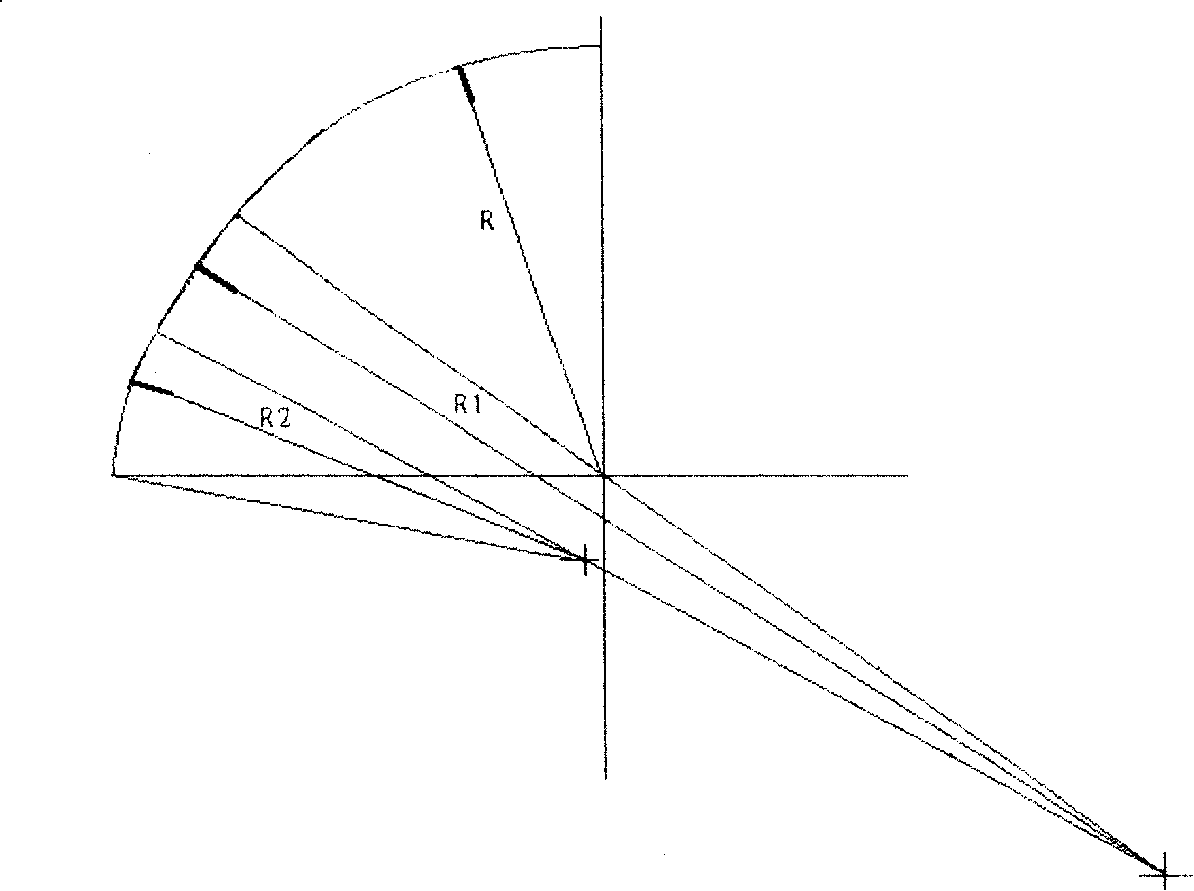

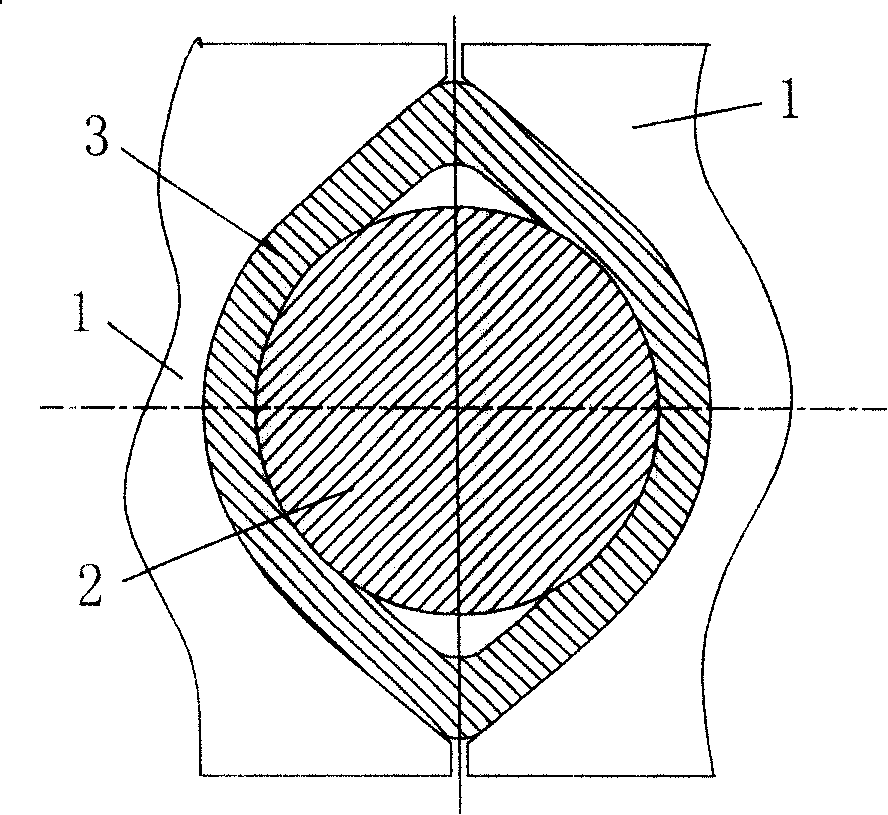

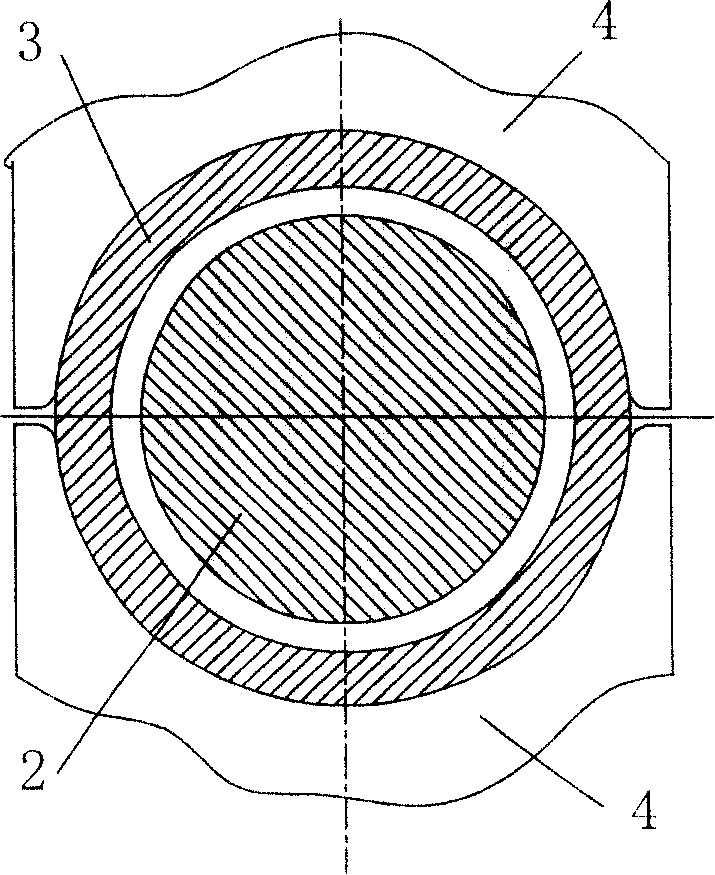

[0026] A method for rolling a hot-rolled seamless steel pipe with a limiting mandrel continuous rolling mill is to design a gap of 5mm between the pipe and the mandrel in the pass of the fifth roll, so that it is easy to remove the pipe; in order to generate the removal gap, the first The third and fourth racks adopt single-radius large side wall arcs to increase the ellipticity of the hole shape, and the side wall radii are 240 and 200 mm; the arc radius of the third to fifth racks' groove bottoms is 89 , 89 and 91.5mm, the value is from small to large, which is different from the original rule that the arc radius of the groove bottom is from large to small. The third and fourth frame groove bottom radii are smaller than the original hole type, but the side wall The radius increases more, and its circumference increases, so that there is enough circumference when entering the fifth frame, and there will be a gap for stripping after the circle is rounded.

[0027] The roll pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com