Power controller assembly and method

A power control and controller technology, which is applied in the direction of temperature control, electrical components, and electrical equipment construction parts using electric methods, can solve the problem of not changing the set point temperature of thermal applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The following description is merely exemplary in nature and is not intended in any way to limit the invention, the disclosure or its application or uses.

[0056] (power controller operating environment)

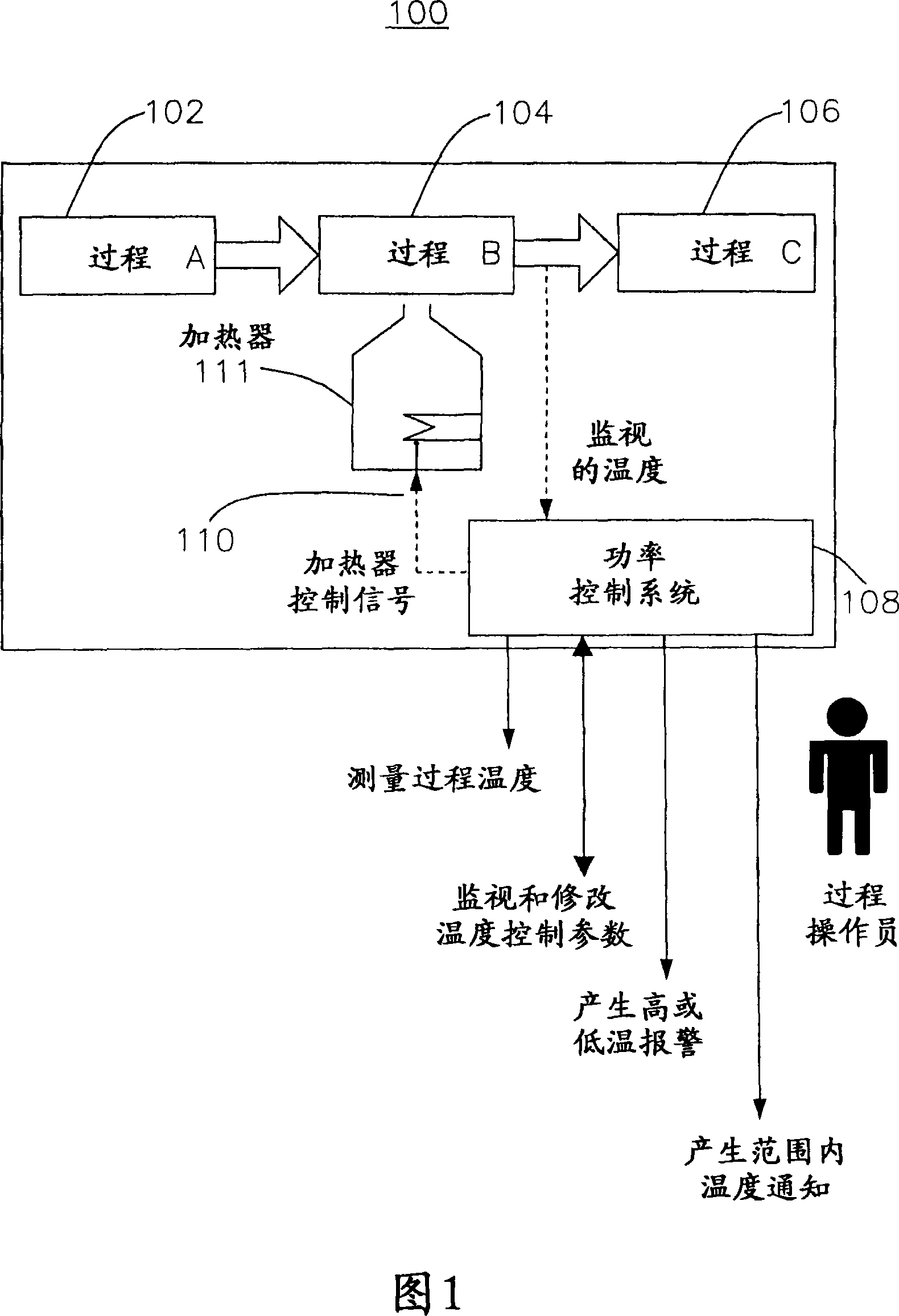

[0057] FIG. 1 illustrates, by way of example, a power control system environment 100 suitable for one or more of the various embodiments of the present disclosure. In FIG. 1 , the heat process contains three processes A 102 , B 104 , and C 106 , with process B 104 requiring heating of the material before proceeding to process C 106 . Such exemplary manufacturing process 100 may include plastic or semiconductor manufacturing processes as examples. In this example, the temperature of Process B 104 is monitored by a sensor (not shown), and the monitored temperature is provided in a sensor signal to a power controller or power control system 108 . The power control system receives the monitored temperature and generates a heater control signal 110 , which may be in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com