Method for preparation of lithium ion battery

A lithium-ion battery and battery case technology, applied in secondary battery manufacturing, electrolyte storage battery manufacturing, secondary battery and other directions, can solve the problems of small electrolyte injection, short cycle life, low battery capacity, etc., and achieve higher capacity. Consistent with cycle performance, pole piece potential, and avoid local overcharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] This embodiment is used to illustrate the preparation method of the lithium ion battery provided by the present invention.

[0017] Prepare 25 identical LP053450ARK type semi-finished lithium-ion batteries according to the following method:

[0018] 100 parts by weight of LiCoO 2 , 2.0 parts by weight of binder PVDF, 4.5 parts by weight of conductive agent acetylene black were added to 70 parts by weight of (NMP), and then stirred in a vacuum mixer to form a uniform positive electrode slurry. This slurry is evenly coated on the aluminum foil with a width of 400 mm and a thickness of 0.016 mm, then dried at 120°C, rolled and cut on a slitting machine to obtain a size of 140.0 mm (length) × 50.0 mm (width). ) × 0.145 mm (thick) positive pole piece.

[0019] 100 parts by weight of negative electrode active material natural graphite, 1.0 parts by weight of binder polyvinylidene fluoride (PVDF) and 1.0 parts by weight of conductive agent carbon black are added in 120 parts...

Embodiment 2

[0024] This embodiment is used to illustrate the preparation method of the lithium ion battery provided by the present invention.

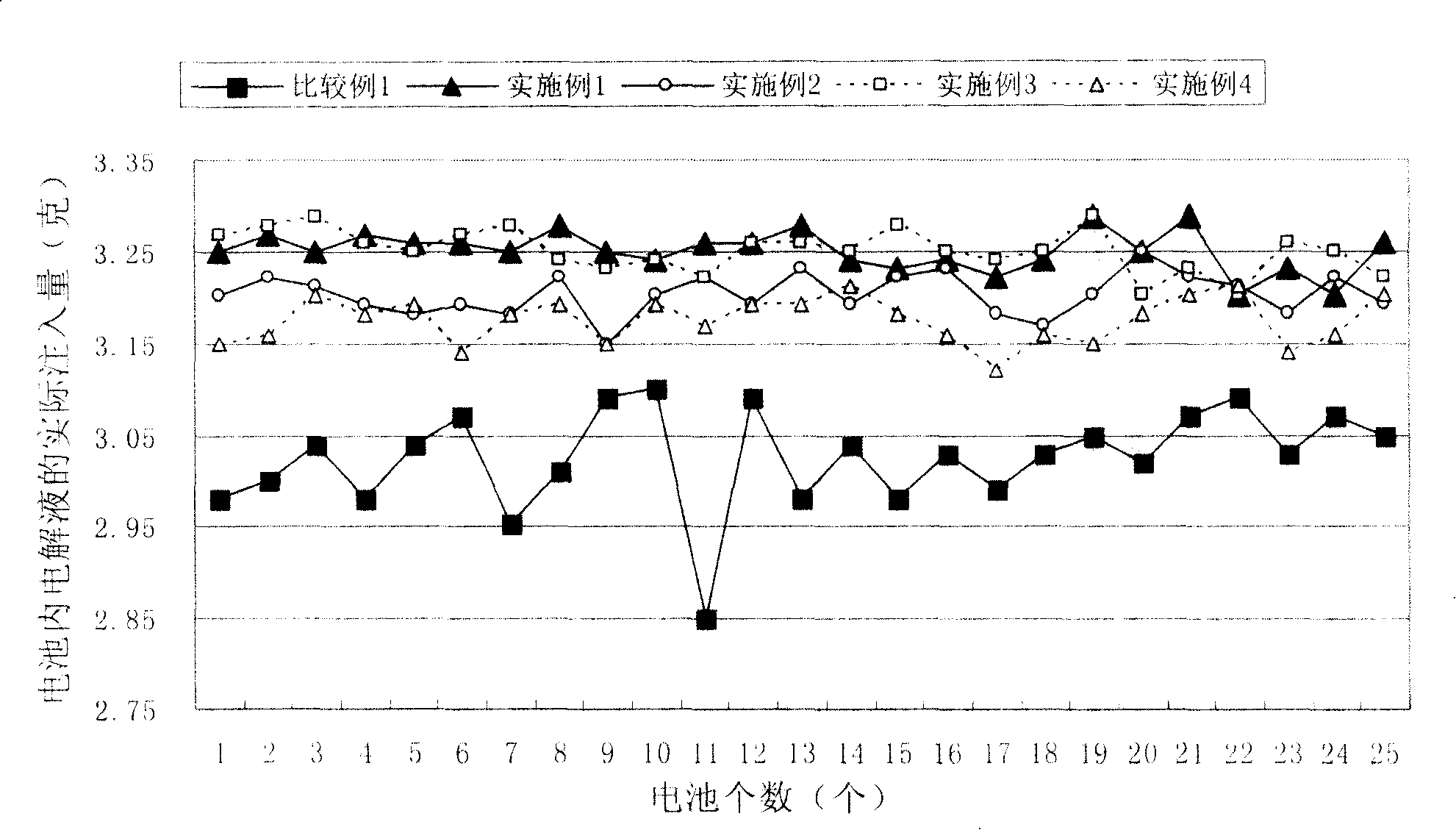

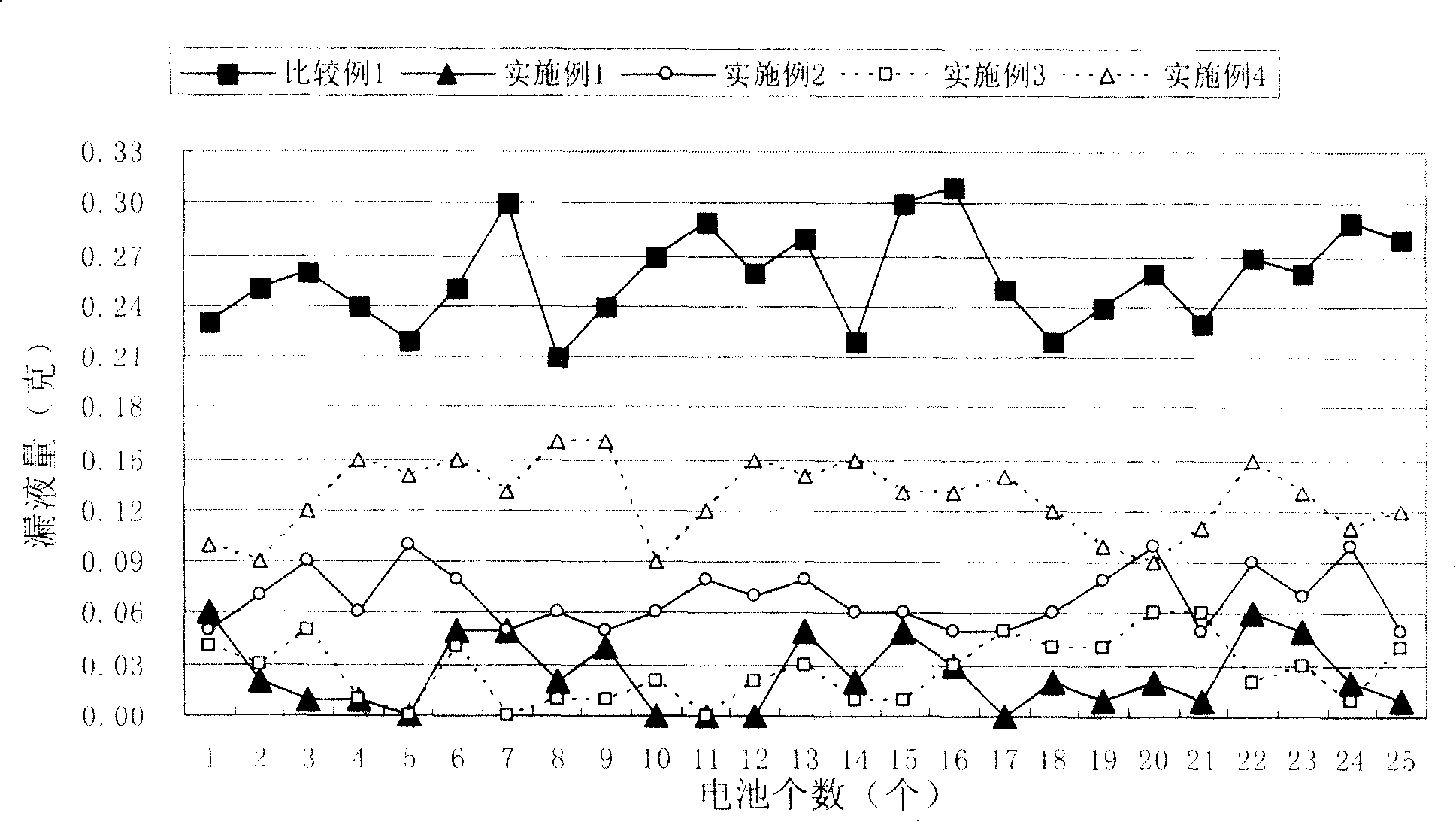

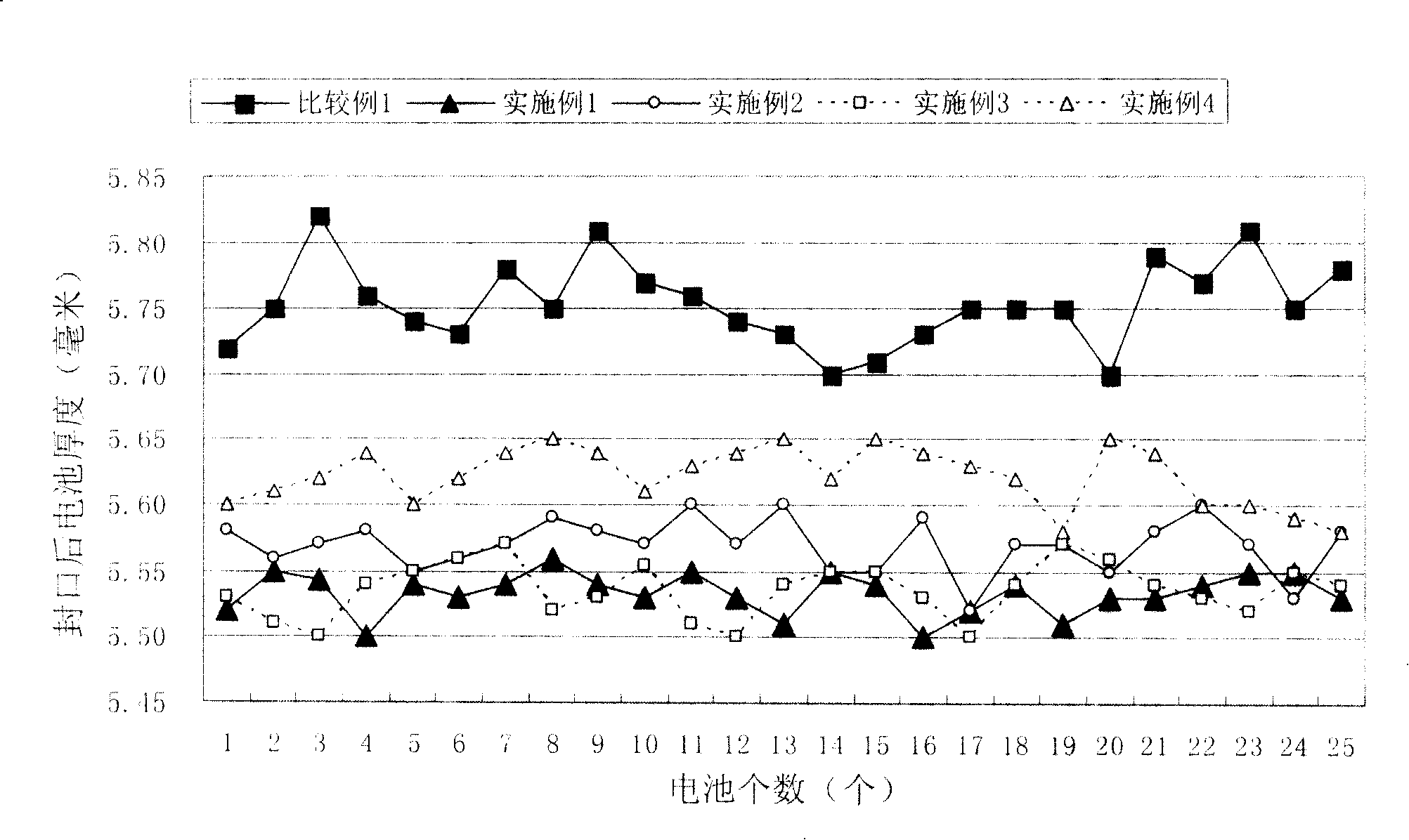

[0025] Prepare 25 completely identical LP053450ARK semi-finished lithium-ion batteries according to the method of the above-mentioned embodiment 1, and the numbers are respectively A26-A50, and then these semi-finished lithium-ion batteries A26-A50 are dried at a temperature of 20°C and a relative humidity of 0.1%. After the chamber was placed for 14 hours, it was squeezed and exhausted, and then the injection port of the electrolyte was sealed to obtain lithium-ion batteries AA26-AA50. value and the difference between the battery weight after liquid injection and the battery weight after sealing (sealing the injection port) to calculate the actual injection volume and leakage volume of the electrolyte, and measure the thickness of the above-mentioned lithium-ion battery at the center point of the battery at the same time. The results are as follow...

Embodiment 3

[0027] This embodiment is used to illustrate the preparation method of the lithium ion battery provided by the present invention.

[0028] Prepare 25 completely identical LP053450ARK type semi-finished lithium-ion batteries according to the method of the above-mentioned Example 1, and the serial numbers are A51-A75 respectively. After standing for 30 hours, squeeze and exhaust, and then seal the injection port of the electrolyte to obtain lithium-ion batteries AA51-AA75. The obtained lithium-ion batteries are weighed, and the difference between the weight of the battery after the liquid injection and the weight of the battery before the liquid injection is obtained. Calculate the actual injection amount and leakage amount of the electrolyte by calculating the difference between the weight of the battery after liquid injection and the weight of the battery after sealing (sealing the injection port), and measure the thickness of the above-mentioned lithium-ion battery at the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com