Virtual supersonic flaw detector and experimental platform for testing probe head performance

An experimental platform, ultrasonic technology, applied in the direction of material analysis, instruments, measuring devices, etc. using sound waves/ultrasonic waves/infrasonic waves, to achieve a good self-learning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

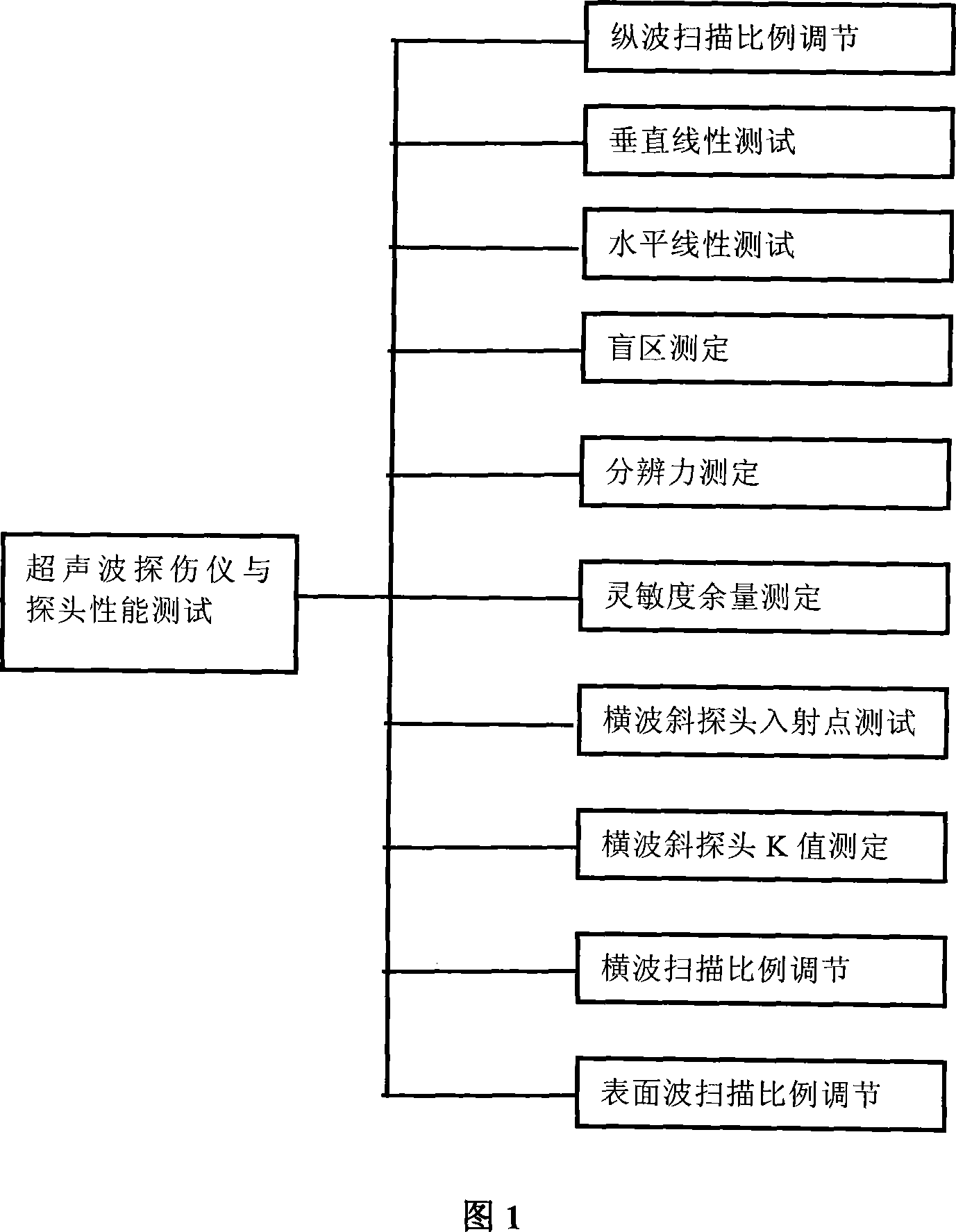

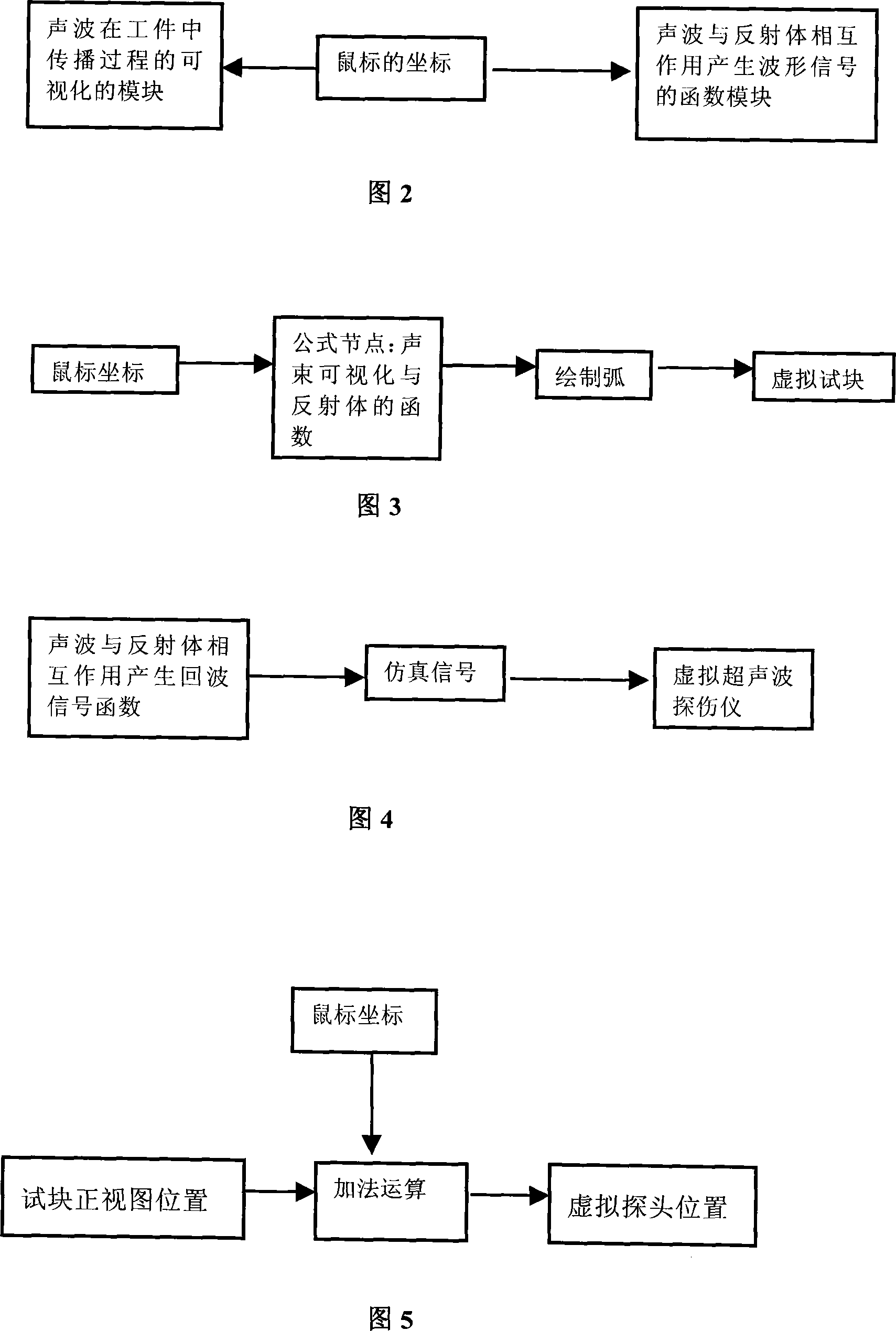

[0017] The invention discloses a set of virtual ultrasonic flaw detector and probe performance testing experiment platform developed by LabVIEW software, virtual ultrasonic flaw detector (CTS-22 analog instrument and HS510 digital instrument), virtual ultrasonic probe (longitudinal wave straight probe, transverse wave Angle probe and surface wave angle probe) and virtual test blocks (standard test block, reference test block and simulated test block) performance index and function index are the same as the real hardware, and the function and state of the virtual hardware can be checked with the mouse (in line with the real experiment) for control, the virtual hardware corresponds and correlates according to the law of ultrasonic propagation, and the experimental process of the virtual ultrasonic flaw detector and probe performance test of the experimental platform is consistent with the actual experimental process.

[0018] The present invention will be further described below ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com