Fuel supply device

A fuel supply device and fuel technology, applied in the direction of liquid fuel feeder, charging system, combustion engine, etc., can solve the problems of torque loss in the sealing part, fuel leakage, motor enlargement, etc., to achieve the prevention of rising and reliability Higher effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiment 1

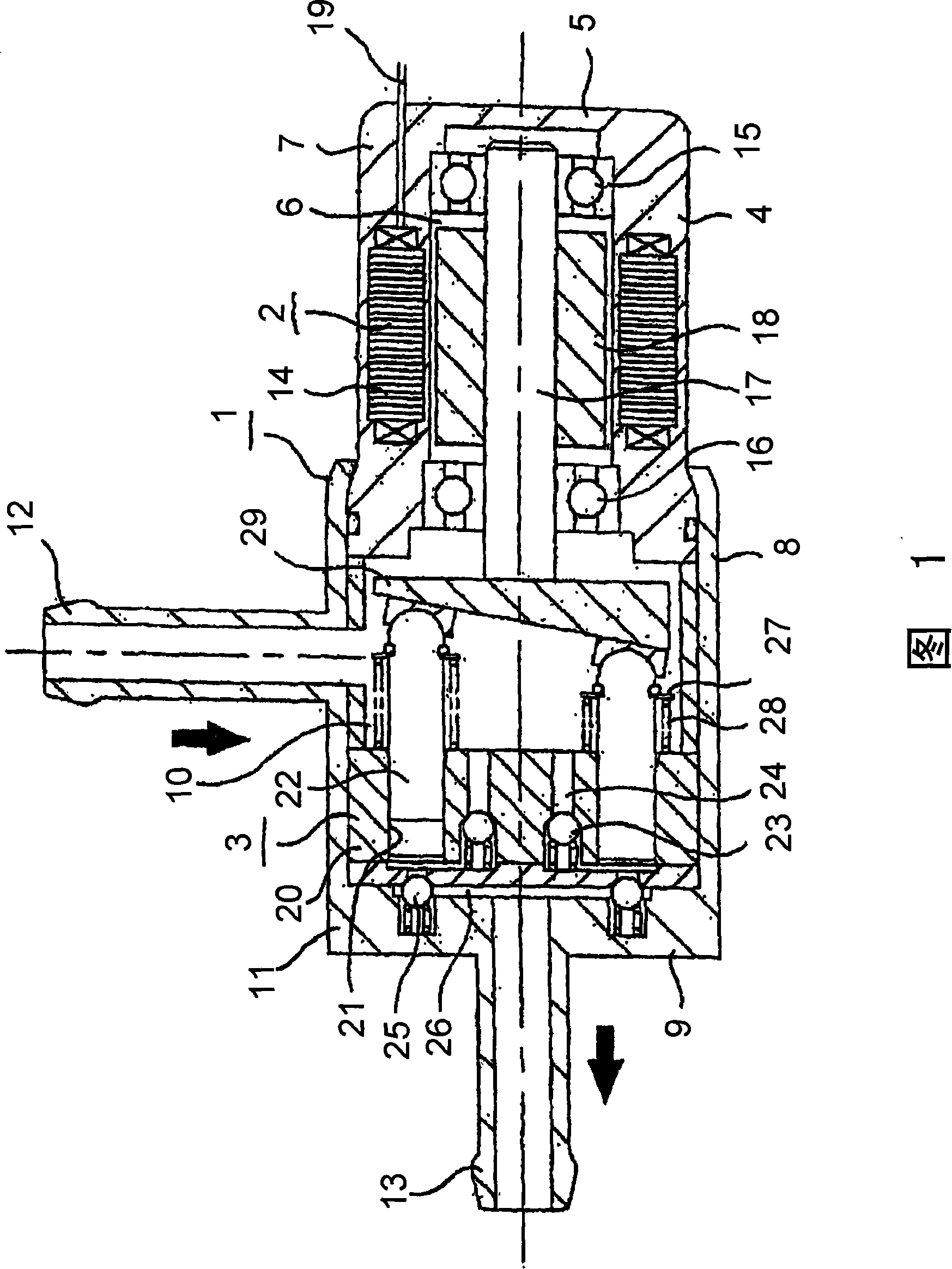

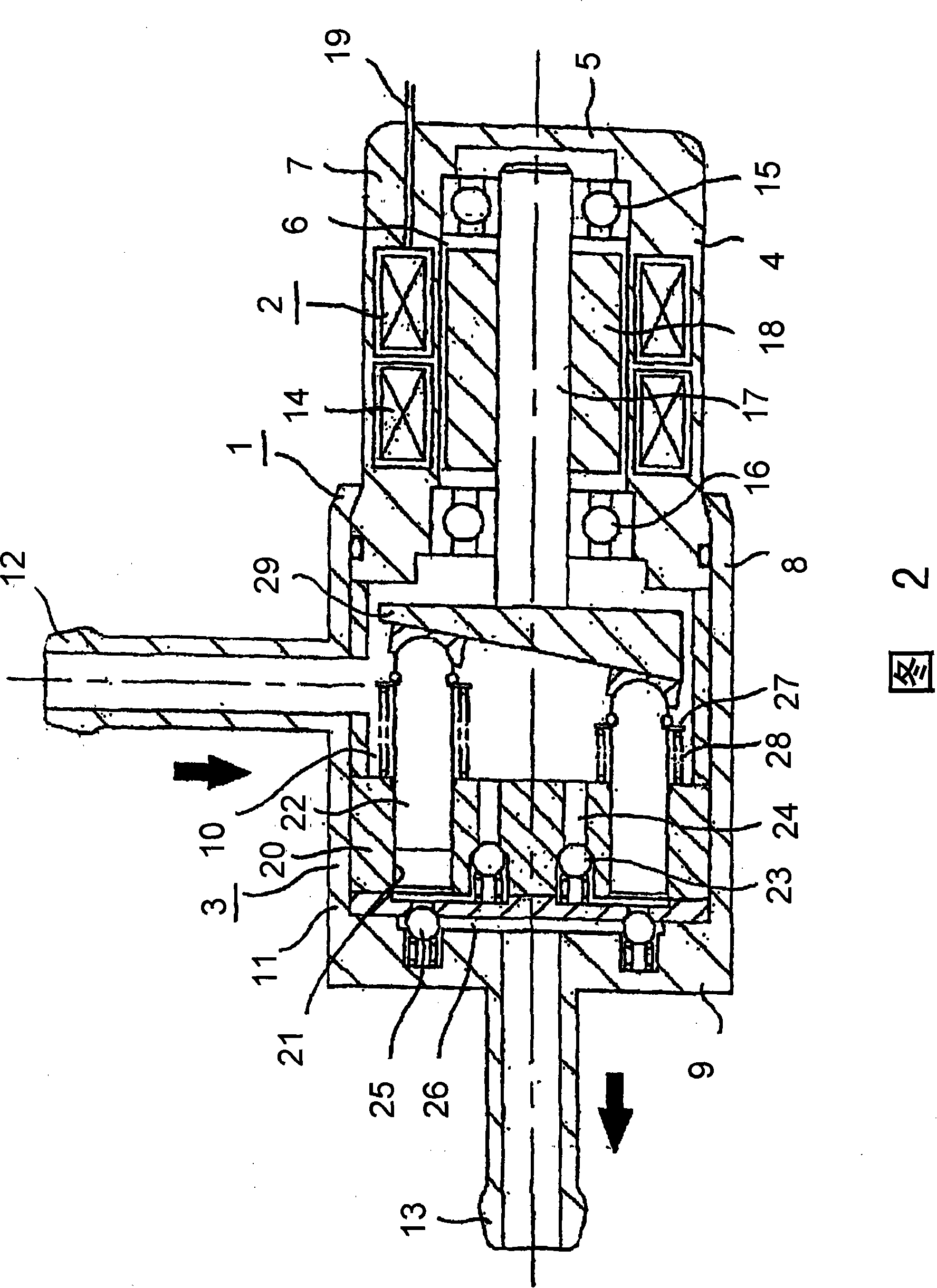

[0026] The fuel supply device of the present invention shown in Fig. 1 comprises: the shell 1 that is generally hollow cylinder as a whole; The electric motor 2 that is arranged in the shell 1; .

[0027] Housing 1 comprises: motor housing 7, has cylindrical wall 4 and end wall 5 as housing wall, is formed with the motor chamber 6 that accommodates motor 2 inside; And pump device housing 11, pump device housing 11 has The cylindrical wall 8 and the end wall 9 form a pump device chamber 10 in which the pump device 3 is accommodated. The open end of the pump housing 11 is firmly connected to the open end of the motor housing 7 by riveting or the like, and the motor chamber 6 and the pump chamber 10 communicate with each other. A fuel inlet 12 is provided on the cylindrical wall 8 of the pump device housing 11 , and a fuel outlet 13 is provided on the end wall 9 . The motor casing 7 is closed except that the open end communicates with the pump device casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com