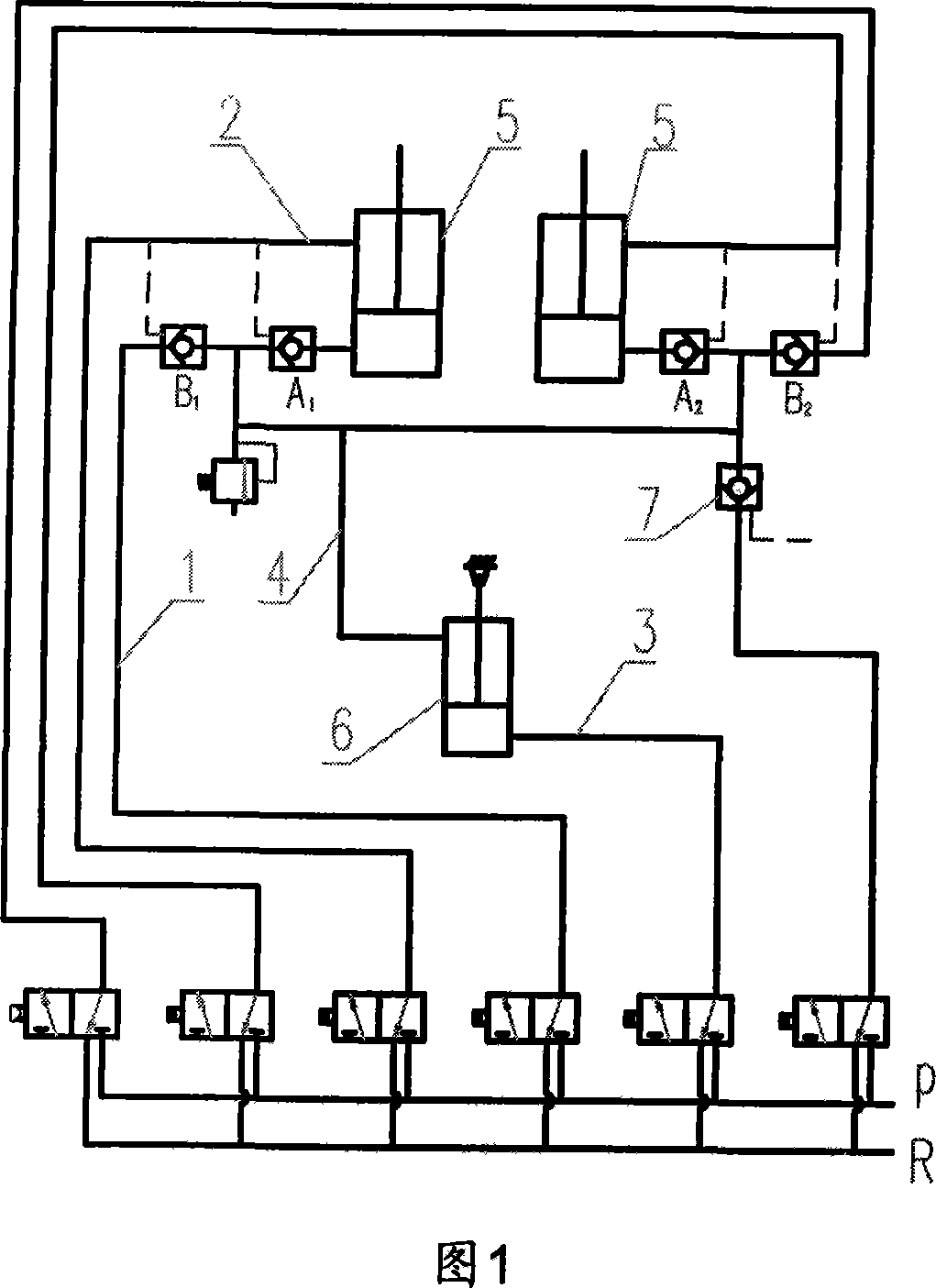

Mining hydraulic support self-boosting system

A hydraulic support and pressurization system technology, which is applied in the direction of pillars/supports, mining equipment, electric fluid pressure control, etc., can solve the problems of high cost and complex structure, and achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

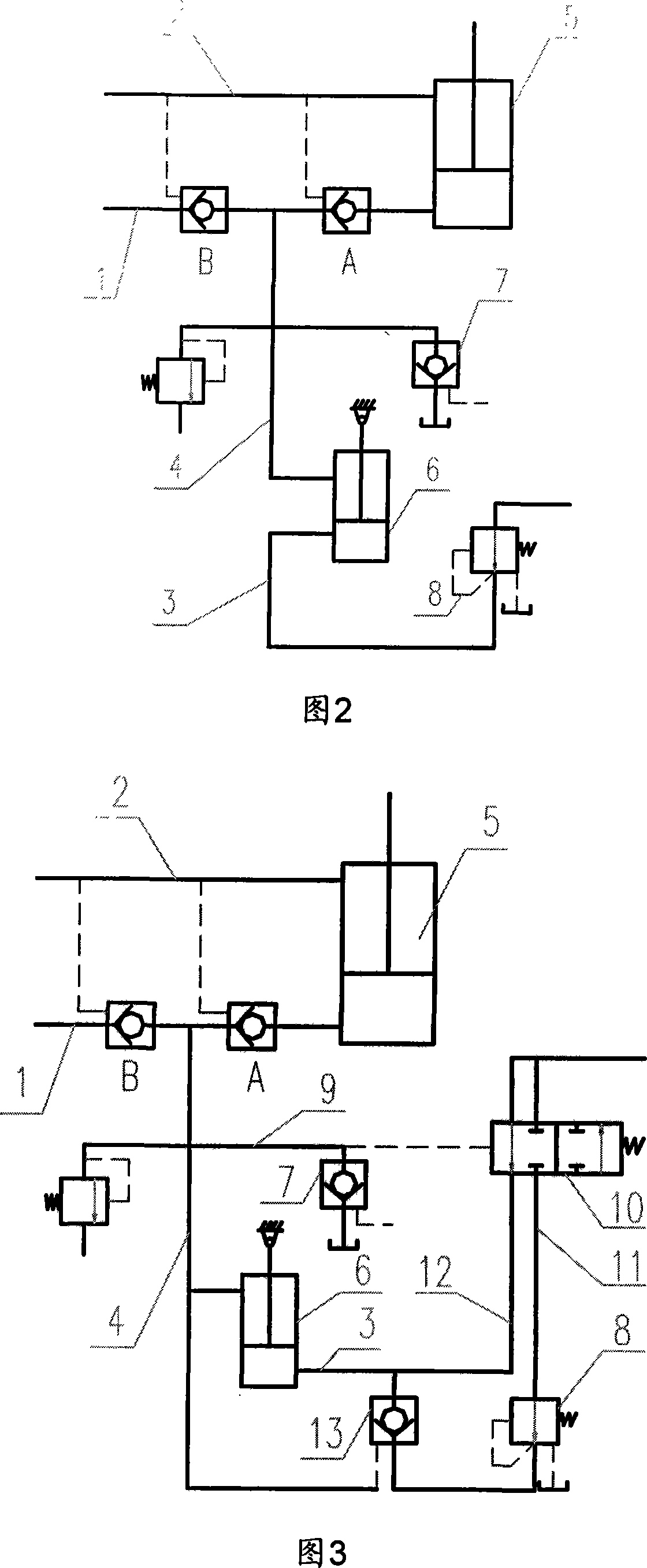

specific Embodiment 2

[0016] Embodiment 2 As shown in FIG. 2 , a pressure reducing valve 8 is provided on the third pipeline 3 of the piston cavity of the bottom jack 6 . The pressure regulating range of the pressure reducing valve can be 10 ~ 31.5MPa, which can be adjusted as required.

specific Embodiment 3

[0017] Embodiment 3 As shown in FIG. 3 , the third pipeline 3 of the piston cavity of the bottom jack 6 is divided into two branches, namely the first branch 11 and the second branch 12 , the pressure reducing valve 8 and the hydraulic control The one-way valve 13 is arranged on the first branch 11 , and the two branches are connected to the main control valve through the control valve 10 .

[0018] The control valve 10 controls the on or off of the two branches. When the first branch 11 is on, the second branch 12 is off; when the second branch 12 is on, the first branch 11 is off.

[0019] The control valve 10 is a two-position four-way valve, the left position of the two-position four-way valve makes the second branch 12 conduct, and the first branch 11 is closed (ie the position in FIG. 3 ); The bit turns the first branch 11 on and the second branch 12 off.

[0020] The transposition of the two-position four-way valve is realized by collecting the pressure signal of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com