Regeneration treatment and cyclic utilization method of printing and dyeing wastewater

A printing and dyeing sewage and treatment cycle technology, which is applied in the field of resource recycling and sewage treatment, can solve the problems of high operating costs in the ozone catalytic oxidation process, achieve the effects of reducing floor space and investment costs, reducing operating pressure, and improving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: Take the continuous test of the present invention in a branch of a certain large-scale printing and dyeing enterprise as an example to further illustrate.

[0033] The enterprise discharges 3,000 tons of printing and dyeing sewage every day during the production process. The quality of the sewage is: chemical oxygen demand 1500-2500mg / L, chromaticity 800-1200 times, pH value 9-14, conductivity 4000-6000μs / cm.

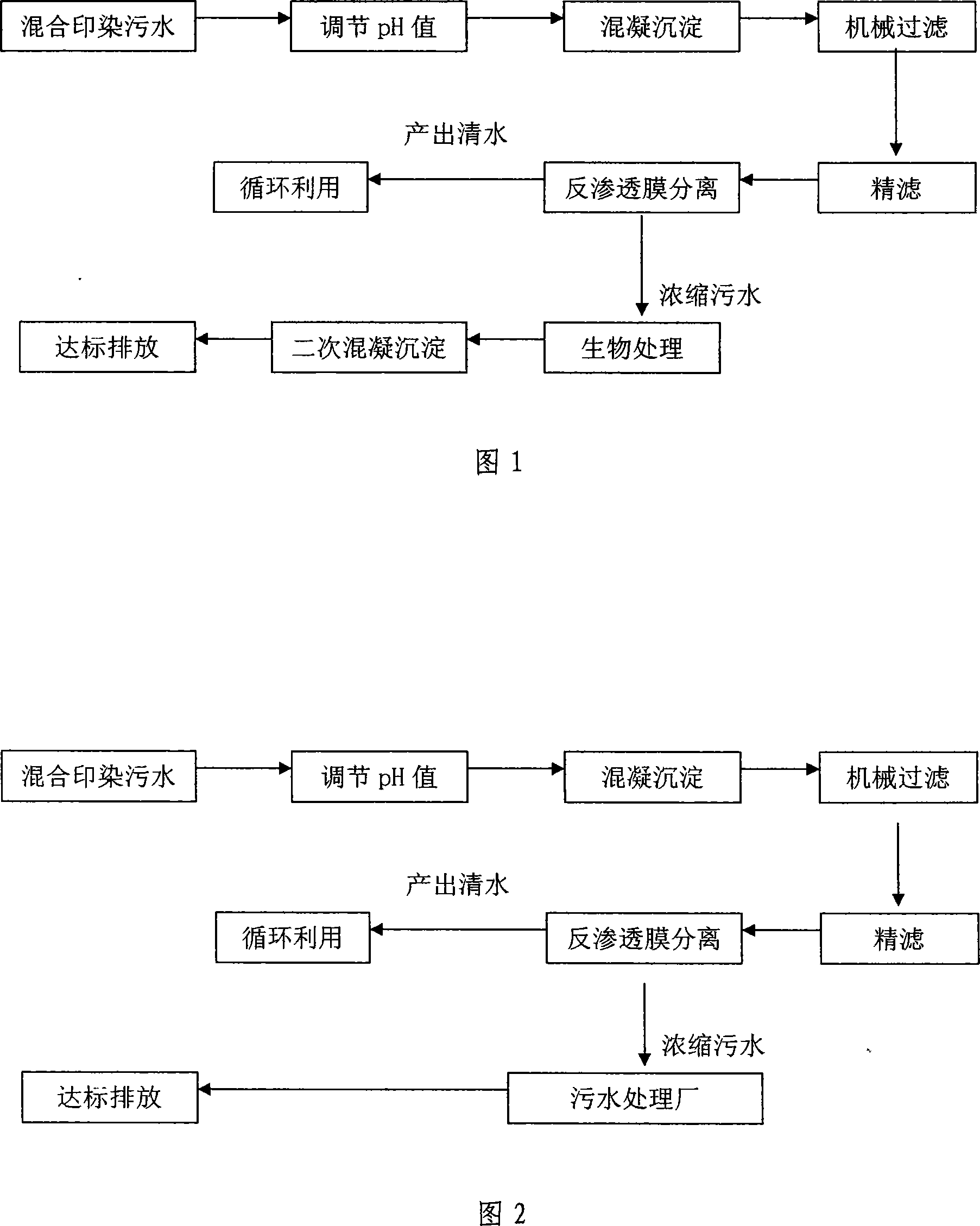

[0034] After a small sample test in the early stage, it was decided to use ferrous sulfate as a coagulant to control the pH of the sewage to 10. The specific process is as follows (Figure 1):

[0035] (1) Adjust pH value: Online real-time detection and automatic addition of acid or alkali to adjust the pH value of mixed printing and dyeing wastewater to 10.

[0036] (2) Coagulation and sedimentation: Add coagulant ferrous sulfate to the sewage in an amount of 900mg / L, stir and react, and settle by gravity.

[0037] (3) Mechanical filtration: The su...

Embodiment 2

[0045] Embodiment 2: Take the engineering application of the present invention in a new printing and dyeing enterprise as an example to further illustrate.

[0046] The enterprise discharges 3,000 tons of printing and dyeing sewage every day during the production process. The quality of the sewage is: chemical oxygen demand 500-700mg / L, chromaticity 600-1000 times, pH value 8-12, conductivity 3000-6000μs / cm.

[0047] After a small sample test in the early stage, it was decided to use ferrous sulfate as the coagulant and polyacrylamide (PAM) as the coagulant aid to control the pH of the sewage to 10. The specific process is as follows (Figure 2):

[0048] (1) Adjust pH value: Online real-time detection and automatic addition of acid or alkali to adjust the pH value of mixed printing and dyeing wastewater to 10.

[0049] (2) Coagulation and sedimentation: Add the coagulant ferrous sulfate in the amount of 800mg / L to the sewage, add the coagulant polyacrylamide (PAM) in the amoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cod | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com