Method for preparing molecular sieve in reaction vessel

A technology of molecular sieves and reactors, which is applied in the direction of molecular sieve compounds, molecular sieves and alkali exchange compounds, chemical instruments and methods, etc., can solve the problems of molecular sieve performance degradation, molecular sieve easy loss, and affecting the physical structure of molecular sieves. Uniform temperature distribution, improving the effect of the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 Preparation of TS-2 molecular sieve by hydrothermal method

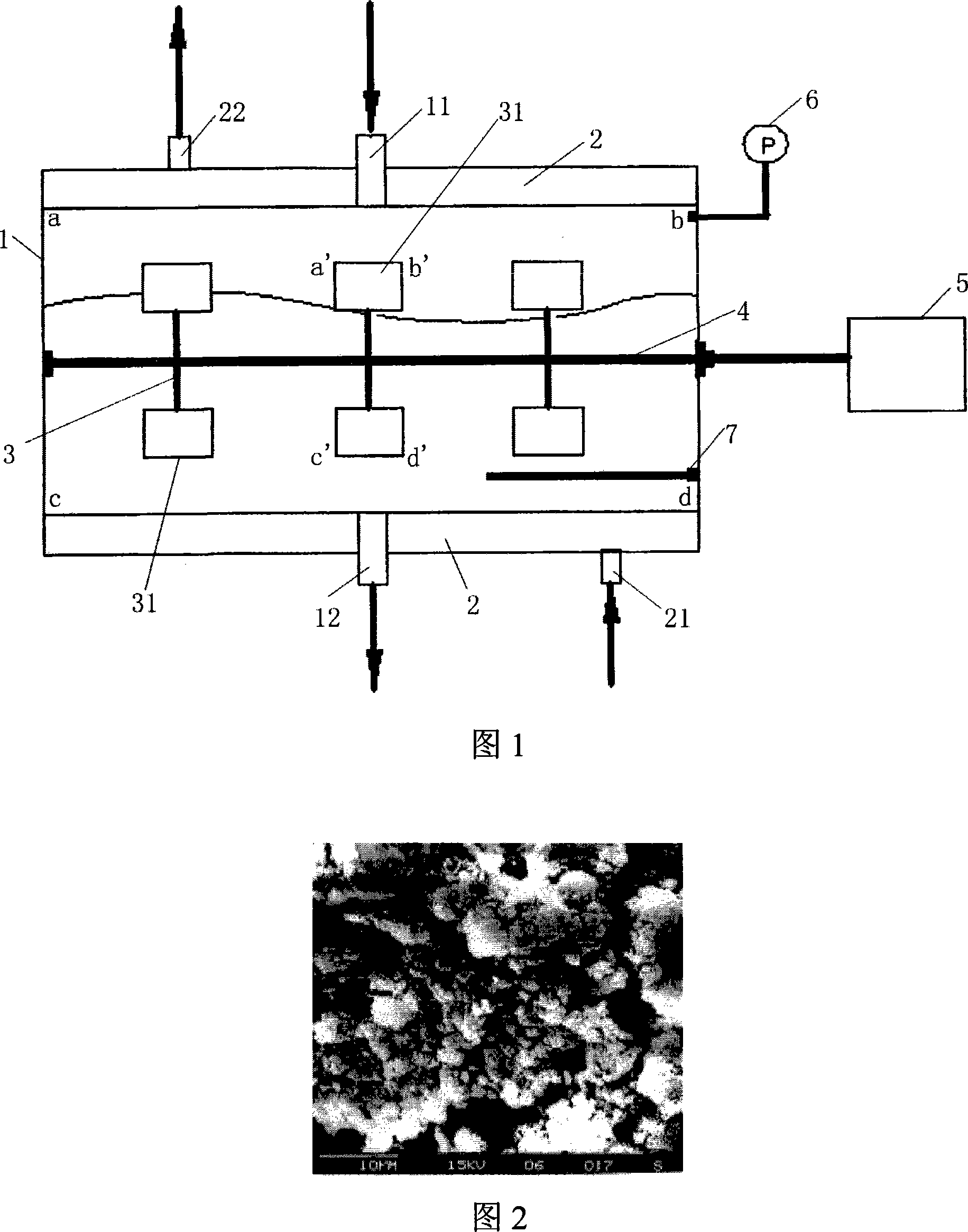

[0044] As shown in Figure 1, the horizontal reactor is a stainless steel pressure reactor, which includes: a kettle body 1, which is provided with a material inlet 11 and a discharge port 12; a jacket 2, which is arranged outside the kettle body 1 , with an inlet 21 and an outlet 22, used for heat removal in the reactor heating and reaction process, when heating or cooling, heating steam or cooling water enters from the jacket inlet 21 and comes out from the jacket outlet 22; and the agitator, the The stirrer includes a stirring motor 5 as a driving device, an axial stirring shaft 4 arranged in the kettle body 1 and driven by the stirring motor 5, and a total of 3 groups of radial shafts fixed on the stirring shaft 4 Stirring paddles 3, each set of stirring paddles 3 has paddle blades 31; the horizontal reactor is also provided with a pressure gauge 6 and a thermocouple 7 inside the tank body 1. The...

Embodiment 2

[0049] Example 2 Preparation of TS-1 molecular sieve by hydrothermal method

[0050] The length-to-diameter ratio of the horizontal reactor is 1.8, the ratio of the diameter of the deformed turbine blade to the inner diameter of the reactor is 0.6, the number of blades of the stirring paddle is 6, and the number of layers of the stirring paddle is 3, and the remainder is the same as in Example 1.

[0051] Add 100mL of 10wt% tetrapropylammonium hydroxide (TPAOH) to the above-mentioned 500mL horizontal reactor, stir at 80rpm for 10min, add 40g of tetraethyl silicate (TEOS) into the reactor, and continue stirring for 1h. Weigh 3g of tetrabutyl titanate (TBOT) and 8g of isopropanol in a beaker, stir well and add dropwise into the reactor, and continue stirring for 5h after the dropwise addition to form TS-1 sol. The reactor was sealed and self-pressure crystallized at 170°C for 72h. After crystallization, filter the product, collect and wash the filter cake, dry the filter cake a...

Embodiment 3

[0052] Example 3 Preparation of ZSM-5 molecular sieve by hydrothermal method

[0053] In a 500mL flask, add 9.04g of sodium silicate and 0.09g of sodium metaaluminate to 300mL of water, stir until a clear solution is formed, then add 11.84g of template agent tetrapropylammonium bromide (TPABr) and continue to stir to form molar The composition is n(Si):n(Al):n(TPABr):n(H 2 (0)=1:0.01:0.4:150 stock solution. The stock solution was transferred into the above-mentioned 500mL horizontal reactor, the stirring speed was controlled at 100rpm, and crystallization was carried out at 170°C for 48h. After the crystallization, the product was filtered, the filter cake was collected and washed until pH = 7, the filter cake was dried at 110°C for 5 hours, and then calcined at 550°C for 5 hours to obtain ZSM-5 molecular sieve. The shape of the obtained molecular sieve particles is more regular than the molecular sieve prepared by the existing vertical reaction kettle, which is spherical, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com