Pinenut kernel testa stripping machine

A technology of peeling machine and pine nuts, which is applied in the fields of shelling, pod removal, and food science. It can solve the problems of low peeling rate, unsuitable use, and high rate of pine nut damage, and achieve the effect of eliminating weak links and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

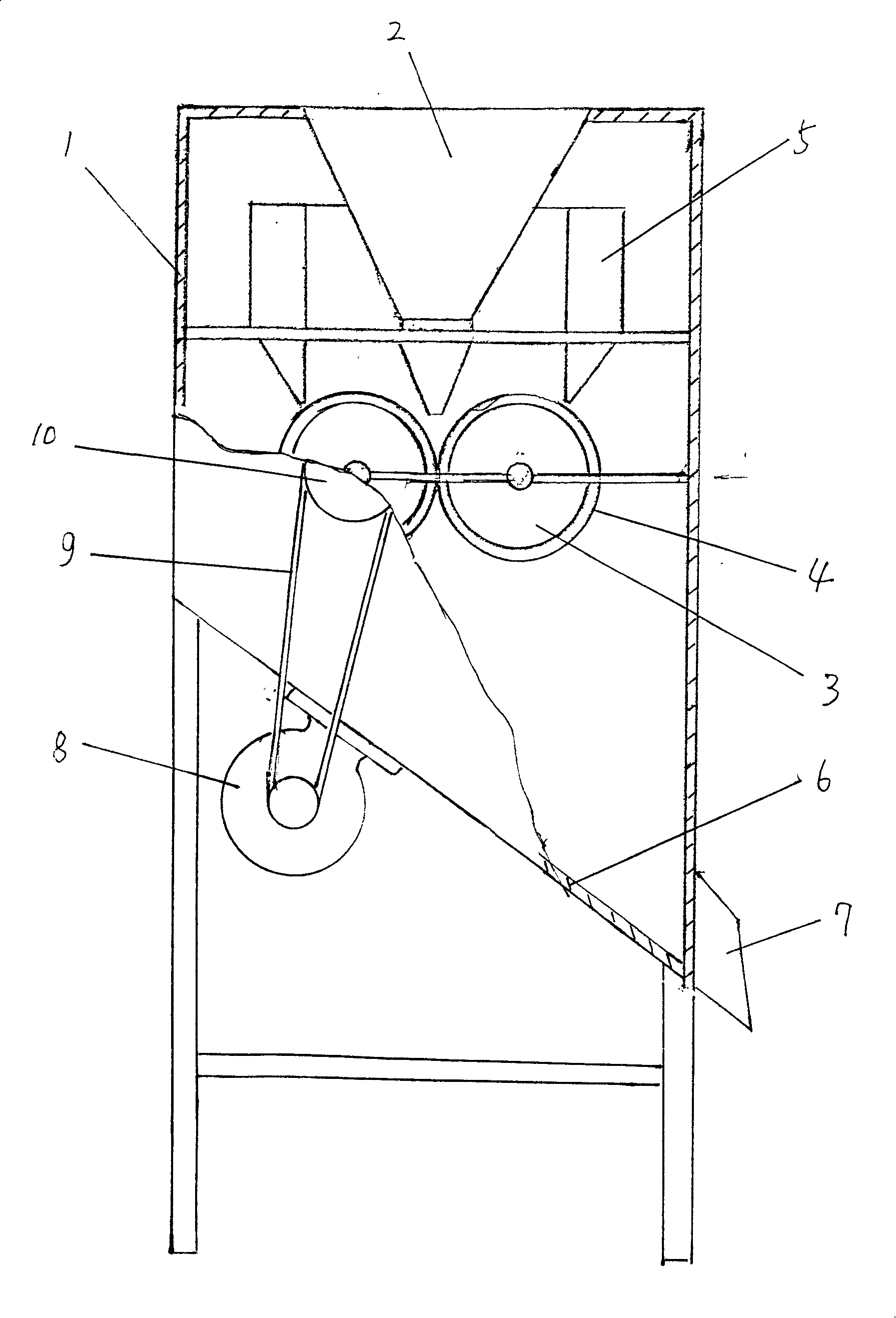

[0012] Provide embodiments of the present utility model below in conjunction with accompanying drawing.

[0013] welded with steel plate figure 1 , 2, 3 shown in the box body 1 and the feeding hopper 2, the outlet width of the lower end of the feeding hopper is controlled at about 8mm, the feeding hopper is installed on the upper mouth of the box body 1, and two rubbing skins are made of metal or high-strength plastic. Roller body 3, the diameter of the roller body is preferably more than 150mm and less than 300mm, and a silicone rubber layer 4 with a thickness of 5-15mm is attached to the circumferential surface of the roller body. The skin rubbing rollers are horizontally arranged below the discharge port of the feeding hopper through the bearings installed on the box body, and there is a gap of 3-6mm between the relative skin rubbing rollers. Establish suction duct 5 above the rubbing roller, and the suction duct is divided into two rubbing rollers, and the air suction por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com