A kind of asparagus peeling processing method

A technology of asparagus and grinding discs is applied in pharmaceutical formulas, peeling of vegetables or fruits, medical preparations containing active ingredients, etc. It can solve the problems of low efficiency and labor consumption, and achieve high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The method for the asparagus peeling processing of the present embodiment, comprises the steps:

[0035] (1) Pretreatment: Wash the fresh asparagus and remove the roots, boil it in water at 100°C for 30 minutes, then take it out and cool it with cold water for 10 minutes, so that the temperature of the fresh asparagus core drops below 20°C, and then dry it with a hair dryer surface moisture;

[0036] (2) freezing: freezing the fresh asparagus that completed step (1) for 10 hours at -30°C;

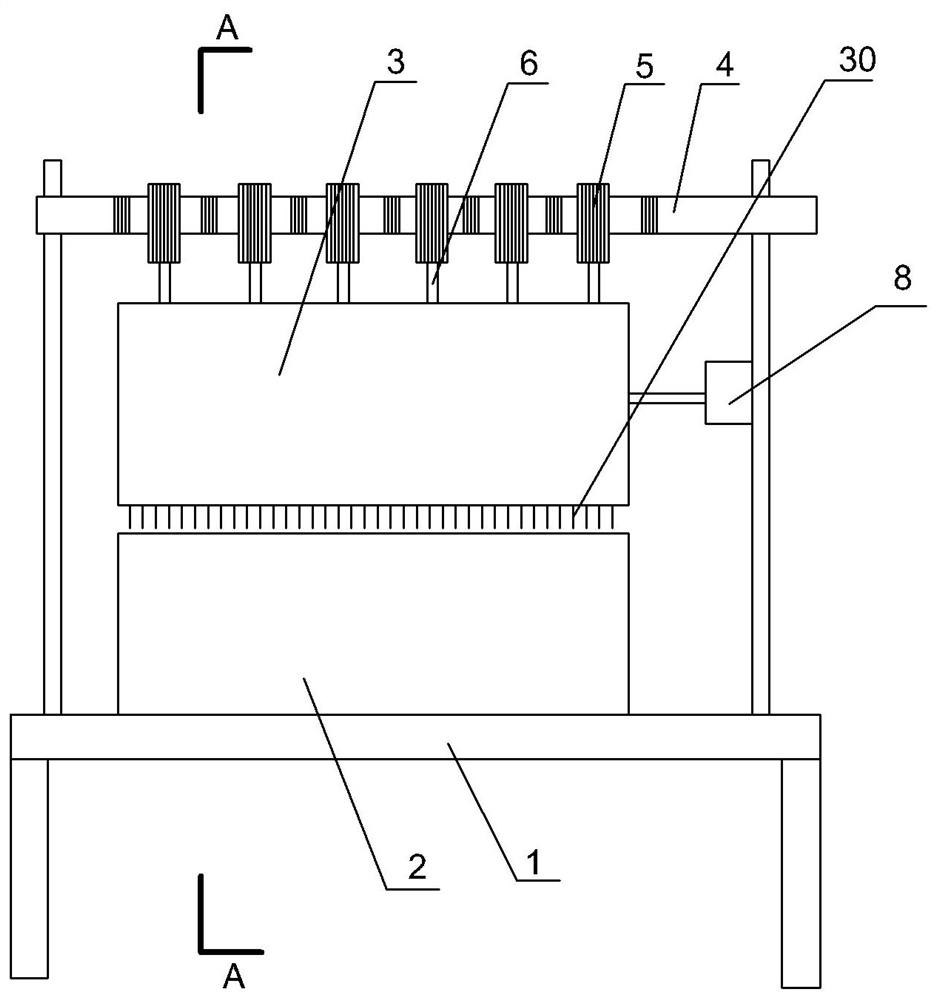

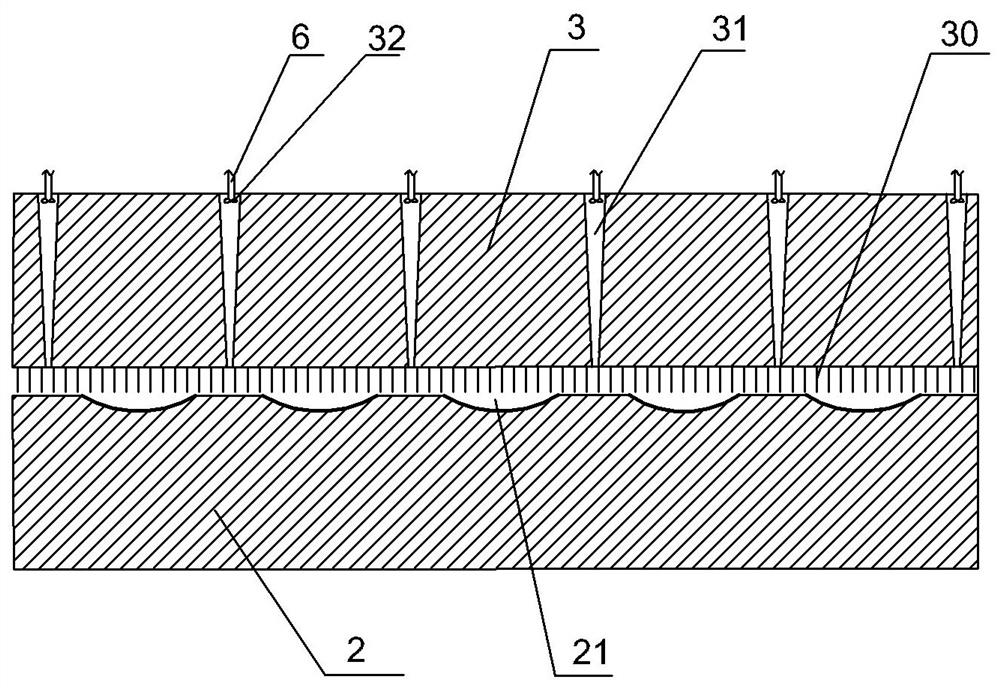

[0037] (3) The fresh asparagus that has been frozen is peeled with the asparagus peeling machine, such as figure 1 and figure 2 As shown, the asparagus peeling machine includes a frame 1, a lower grinding disc 2 is installed on the frame 1 with fixing bolts, an upper grinding disc 3 is arranged above the lower grinding disc 2, and rollers are installed on the upper grinding disc 3, and an upper grinding disc is arranged on the frame 1 The adjustment mechanism, the upper grinding ...

Embodiment 2

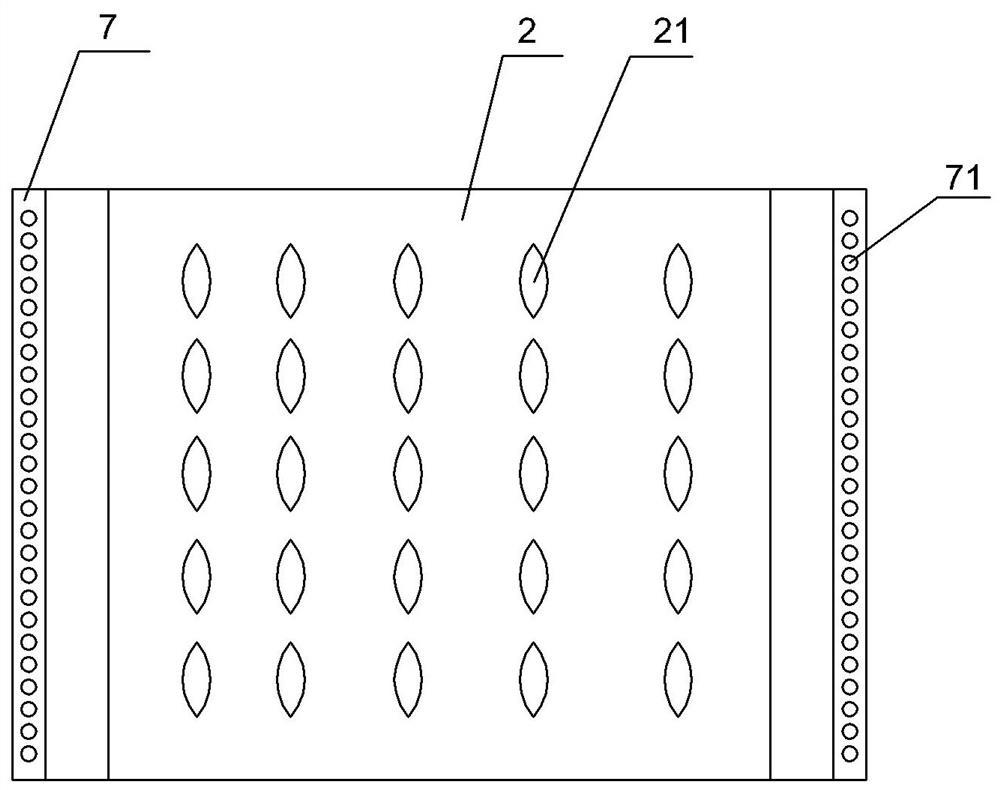

[0042] This embodiment is improved on the basis of Embodiment 1, and the difference from Embodiment 1 is that this embodiment needs to grind asparagus twice, and this embodiment adds a limiter to prevent asparagus from slipping out In the accommodating cavity 21 , the limiting member includes a first limiting buckle and a second limiting buckle detachably connected to the inner wall of the accommodating cavity 21 .

[0043] When grinding for the first time, three first limit buttons are evenly arranged on the inner wall of the accommodation cavity 21, and then the asparagus is ground and peeled.

[0044] When grinding for the second time, a second limit buckle is set between two adjacent first limit buckles, and then the first limit buckle is removed, and then the asparagus is ground and peeled, so that the first time of grinding can be ground and peeled. The part where the asparagus epidermis is blocked by the first limit buckle is also removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com