Customer replaceable unit assembly

A technology that replaces units and users, and is applied in the directions of object supply, electrical recording process applying charge pattern, equipment for electrical recording process applying charge pattern, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

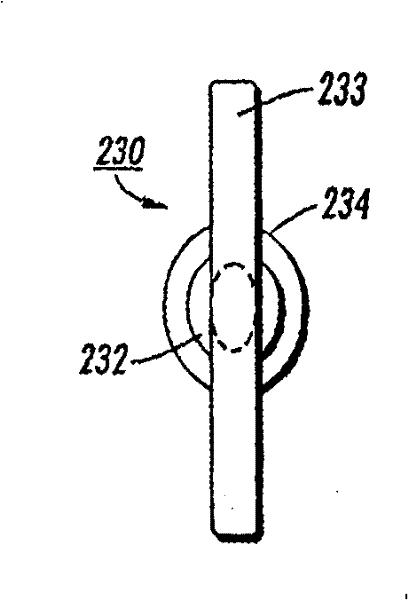

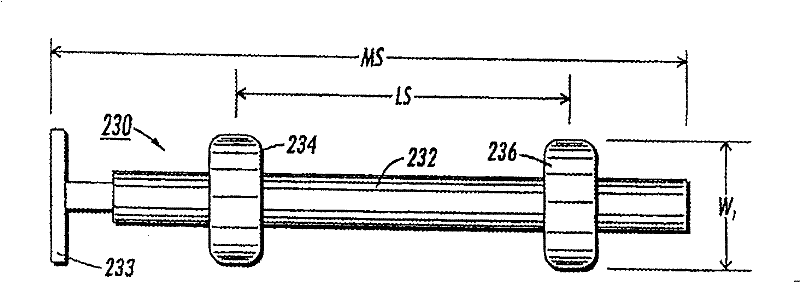

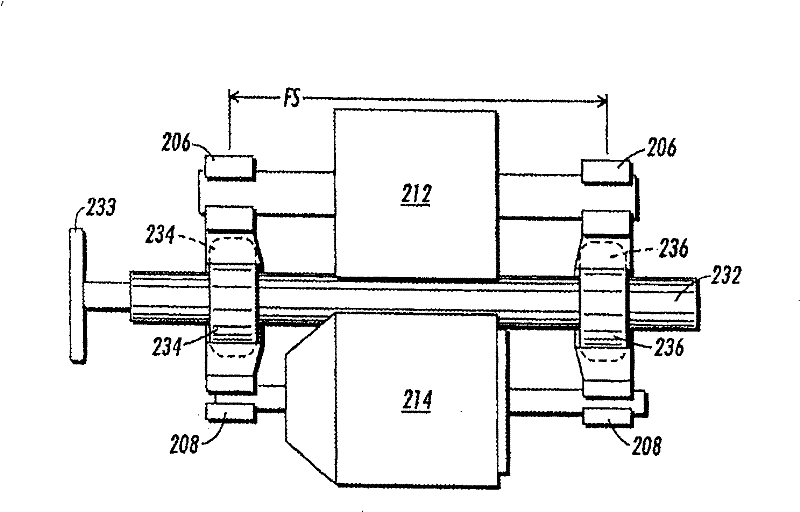

[0012] now refer to figure 1 , shows a customer replaceable unit (CRU) frame 202 for the continuous paper nip assembly mounted (without nip forming rollers thereto) in cavity 120 of section 110 of paper processing machine 100. For example, the machine may be a xerographic copier, and the feed unit may be a CRU such as a compact document feeder. The fit of the CRU frame 202 in the cavity 120 is such that even with nip forming rollers fitted thereto, the feeder assembly will operate in such a section without obstructing any other adjacent machines part. as in figure 2 As illustrated in , the CRU frame 202 is designed such that when the feed roller 212 and the feed roller 214 are assembled thereon, one roller contacts the other to form the feed nip 216 .

[0013] now refer to all Figure 1 to Figure 5 , illustrating details of a paper feeder assembly such as a customer replaceable unit (CRU) assembly 200 of the present specification. The CRU assembly 200 is equally suitable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com