Degreasing agent and preparing method therefor

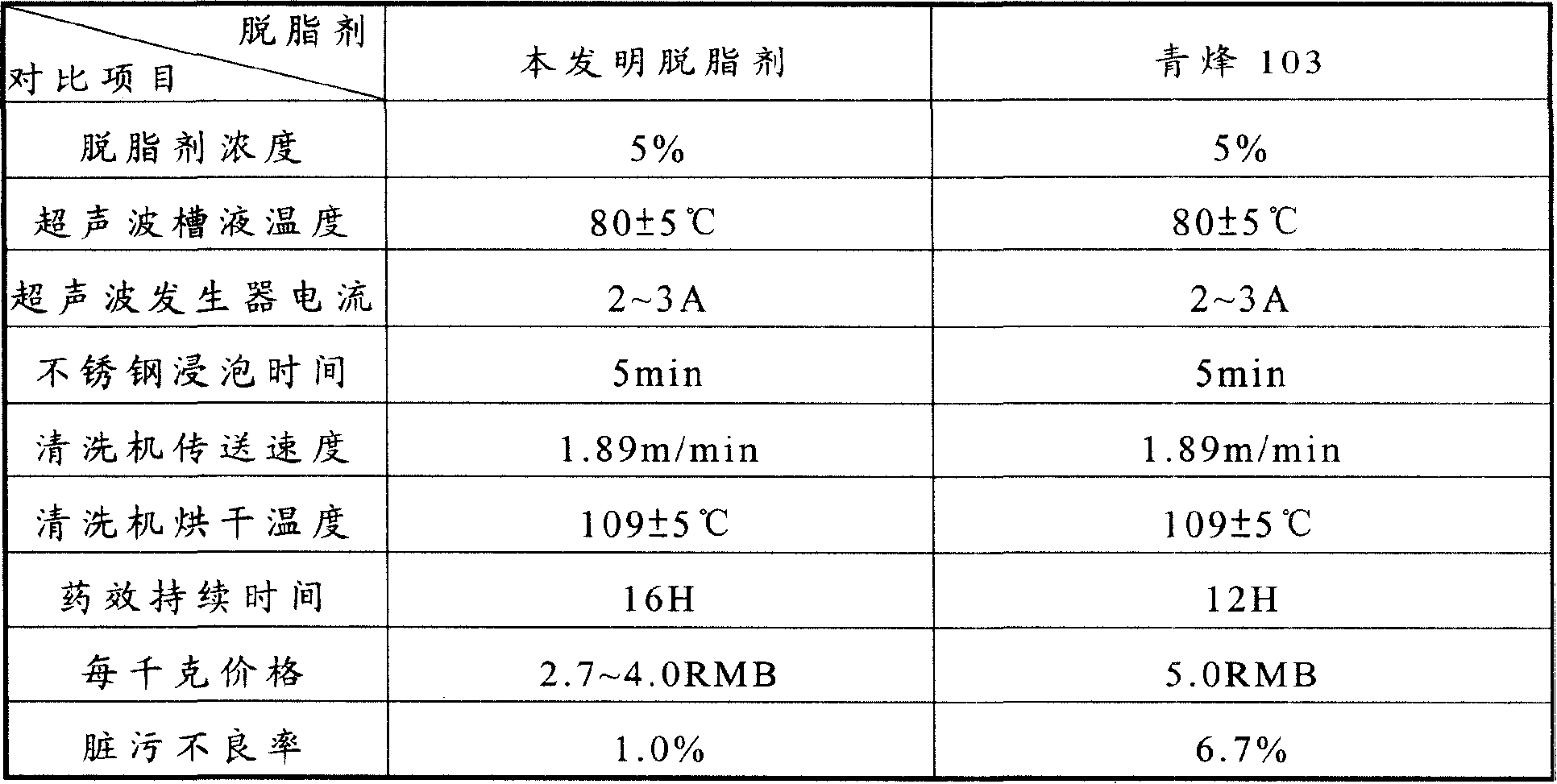

A preparation method and degreasing agent technology, applied in the direction of detergent compounding agent, chemical equipment and method, detergent composition, etc., can solve the problem that the effective cleaning of degreasing surface cannot be satisfied, the effect of surfactant on degreasing effect, and the duration of drug effect Short and other problems, to achieve the effect of long duration of drug effect, low cost, good degreasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The degreasing agent in the preferred embodiment of the present invention can be applied to cleaning the surface of stainless steel.

[0010] The degreasing agent includes trisodium phosphate (Na 3 PO 4 ), sodium silicate (Na 2 SiO 3 ), sodium carbonate (Na 2 CO 3 ), sodium dodecylbenzenesulfonate (C 18 h 29 NaO 3 S), sodium hydroxide (NaOH) and octylphenol polyoxyethylene ether and other components. Among them, sodium dodecylbenzenesulfonate and octylphenol polyoxyethylene ether are respectively surfactants, the sodium dodecylbenzenesulfonate is a powdery solid, and the octylphenol polyoxyethylene ether is viscous liquid. The weight percent of the components of the above-mentioned degreasing agent is: 31% to 41% of trisodium phosphate, 18% to 23% of sodium silicate, 8% to 12% of sodium carbonate, 2% to 6% of dodecyl Sodium benzenesulfonate, 25.5%-29.5% sodium hydroxide and 0.8%-1.7% octylphenol polyoxyethylene ether. The weight percent composition of this de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com