Method for preparing silica steam plating material

A technology of silicon dioxide and evaporation materials, applied in vacuum evaporation coating, metal material coating process, sputtering coating, etc., can solve the problems of inconsistent density, large volume difference, and decline in yield, and achieve distribution uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

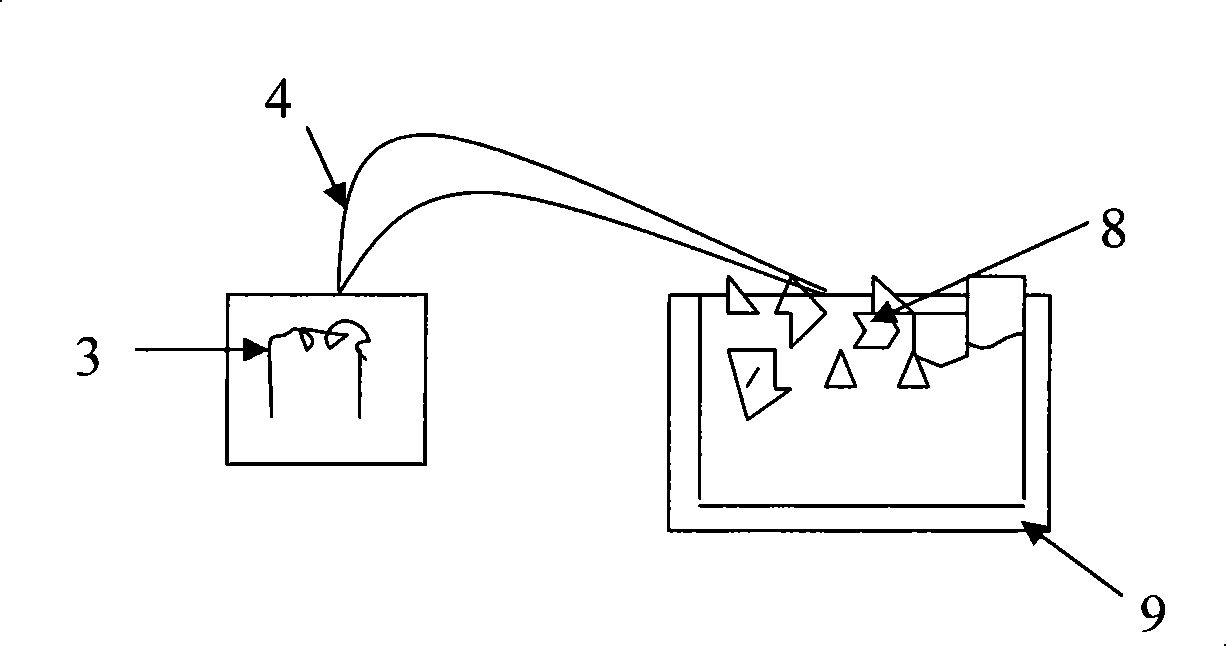

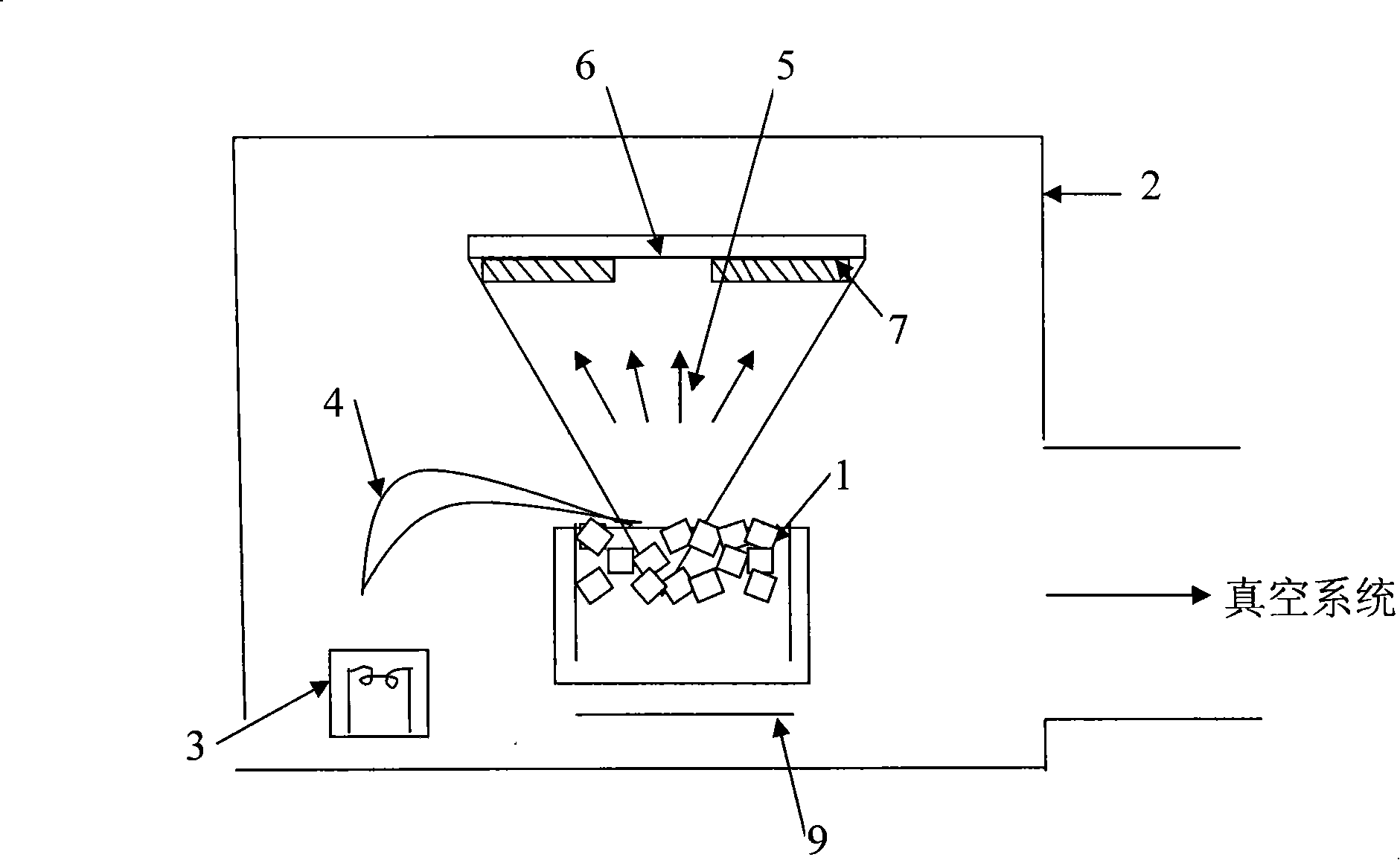

[0020] Combine the following figure 2 For further description, a method for preparing a silicon dioxide evaporation material comprises the following steps in sequence:

[0021] First, apply anaerobic adhesive on the material board, stick a group of identical silica rods side by side on the material board and dry them; Plates are arranged at intervals between the cutting sheets and the partitions, and are fixed side by side on the main shaft of the grinder. The distance between the two adjacent cutting sheets is the diameter of the silica rod, which ensures that the silica rod The length is equal to the diameter, and then the material plate bonded with the silica rod is correspondingly fixed on the grinding machine console, clamped and cut to form silica particles; finally, the silica particles are shoveled from the material plate Next, wash with boiling water and dry to form a silica evaporation material.

[0022] The diameter of the silica rod can be selected as 1.0mm, 1.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com