Mining waste containing pyrite, in the culture of iron-oxidizing and sulfur-oxidizing microorganisms

A technology of sulfur oxidizing microorganisms and pyrite, which is applied in the field of natural microorganisms, can solve the problems of increasing impurities, not knowing that pyrite is effectively used as an energy source for biomass growth, and being impractical, and achieving the effect of high production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

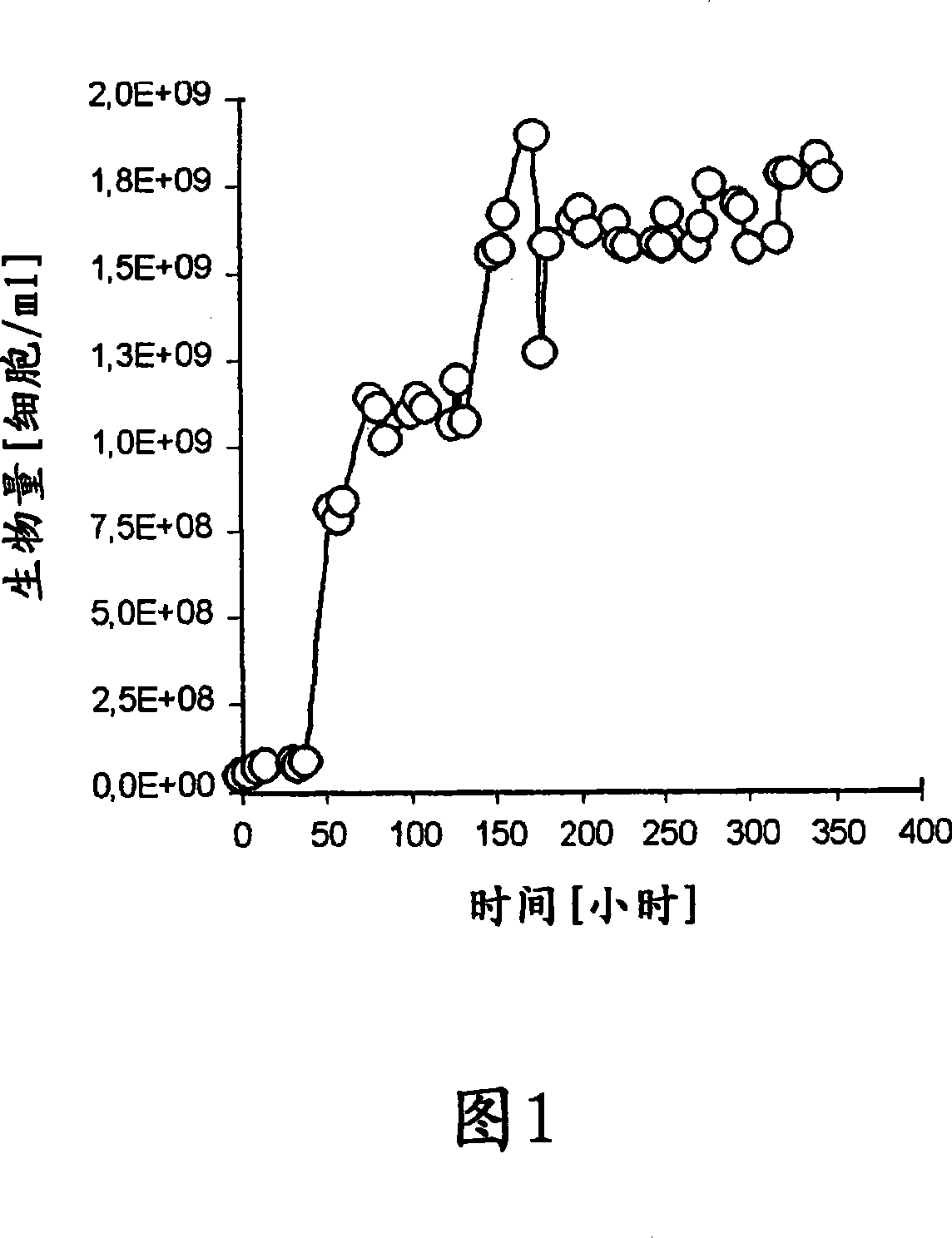

[0054] In order to determine the growth kinetics and biomass production of combinations of Wenelen DSM 16786 and Licanantay DSM 17318 microorganisms, experiments were carried out using the following protocol using a medium modified by the incorporation of sweep tailings:

[0055] Program

[0056] Bacterial growth occurs at 6m 3 effective volume of the reactor.

[0057] A medium for the propagation of microorganisms was prepared by suspending the scavenging tailings (at 1.25% pulp concentration) in a nutrient solution consisting of: 75 g FeSO 4 / L, 0.99g (NH 4 ) 2 SO 4 / L, 0.128g NaH 2 PO 4 ·H 2 O / L, 0.0525g KH 2 PO 4 / L, 0.1gMgSO 4 ·7H 2 O / L, 0.021g CaCl 2 / L. Adjust the pH of the medium to 1.8.

[0058] To start the culture, 5,400 L of medium was mixed with 600 L of bacterial inoculum with Wenelen DSM 16786 and Licanantay DSM 17318 microorganisms.

[0059] In order to allow microorganisms to grow in the reactor, provide enriched 0.5% CO 2 air. The temperature...

Embodiment 2

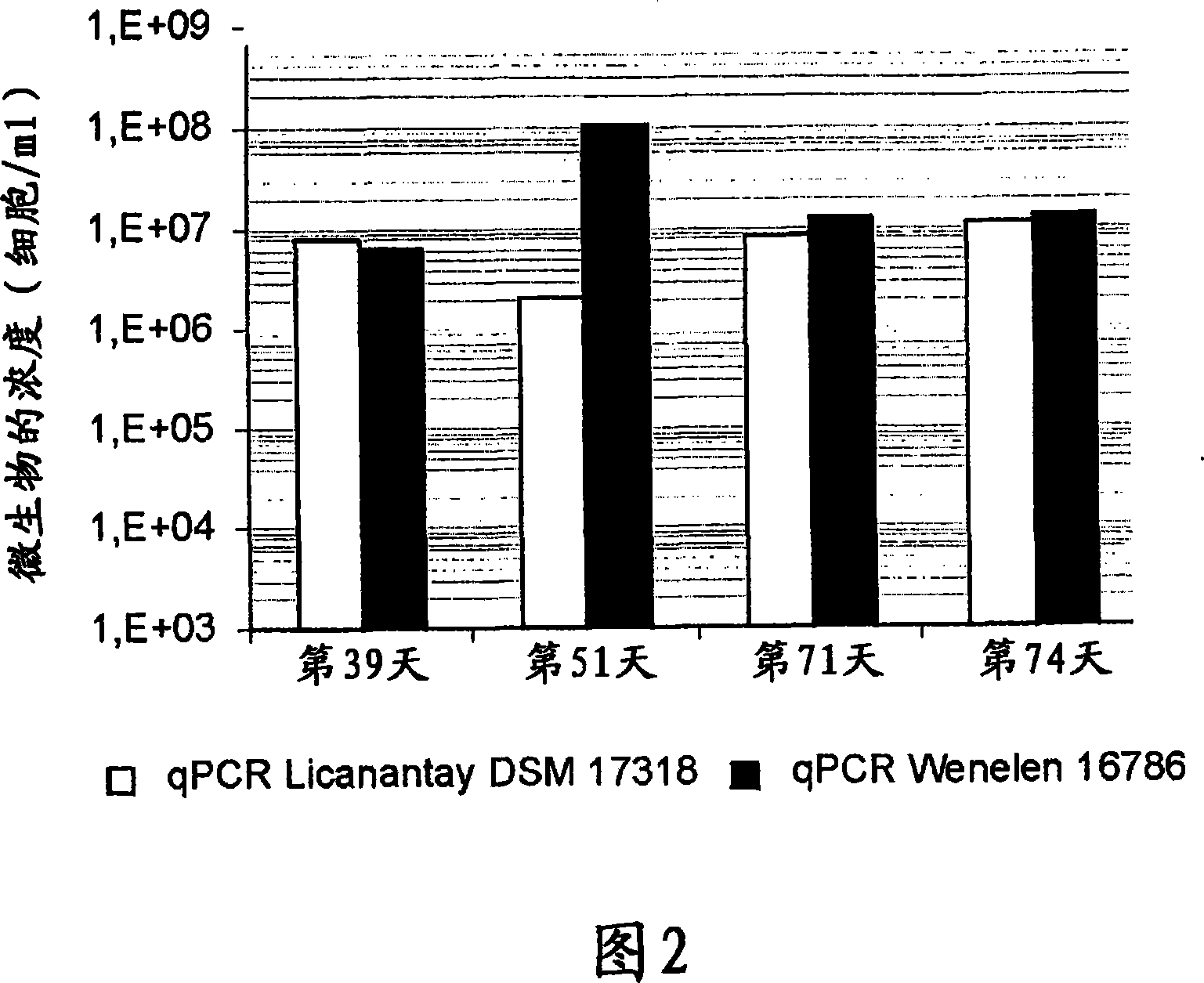

[0064] In order to demonstrate that a combination of Wenelen DSM 16786 and Licanantay DSM 17318 microorganisms can be effectively continuously propagated using a medium modified by the incorporation of sweep tailings, the following protocol was used.

[0065] Program

[0066] Bacterial growth occurs at 50m 3 in industrial reactors.

[0067] A medium for microbial propagation was prepared by suspending the scavenging tailings (at 0.125% slime concentration) in a nutrient solution consisting of: 8 g FeSO 4 / L, 0.99g (NH 4 ) 2 SO 4 / L, 0.128g NaH 2 PO 4 ·H 2 O / L, 0.0525g KH 2 PO 4 / L, 0.1gMgSO 4 ·7H 2 O / L, 0.021g CaCl 2 / L. Adjust the pH of the medium to 1.8.

[0068] To start culturing, place 44m 3 The culture medium with Wenelen DSM 16786 and Licanantay DSM 17318 microorganisms 6m 3 The bacterial inoculum was mixed.

[0069] In order to allow microorganisms to grow in the reactor, provide enriched 0.5% CO 2 air. The temperature of the reactor was controlled a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com