Grinding wheel chuck

A technology for chucks and grinding wheels, which is applied to devices for fixing grinding wheels, parts of grinding machine tools, and metal processing equipment. It can solve problems such as insufficient contact rigidity, achieve reasonable positioning, increase cutting force, and expand the application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

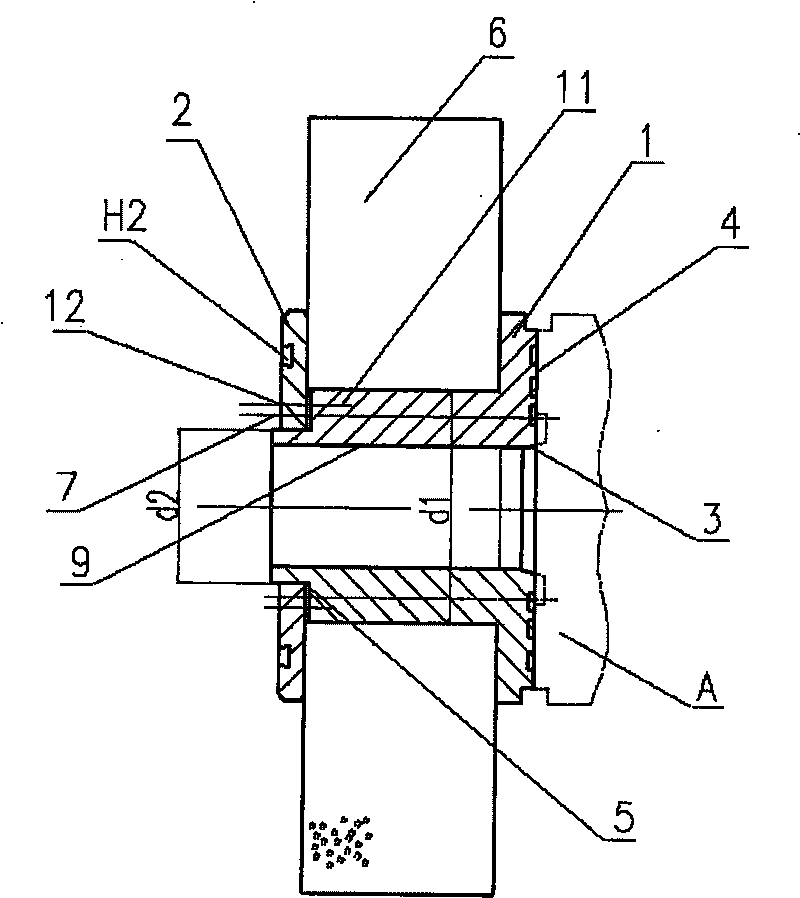

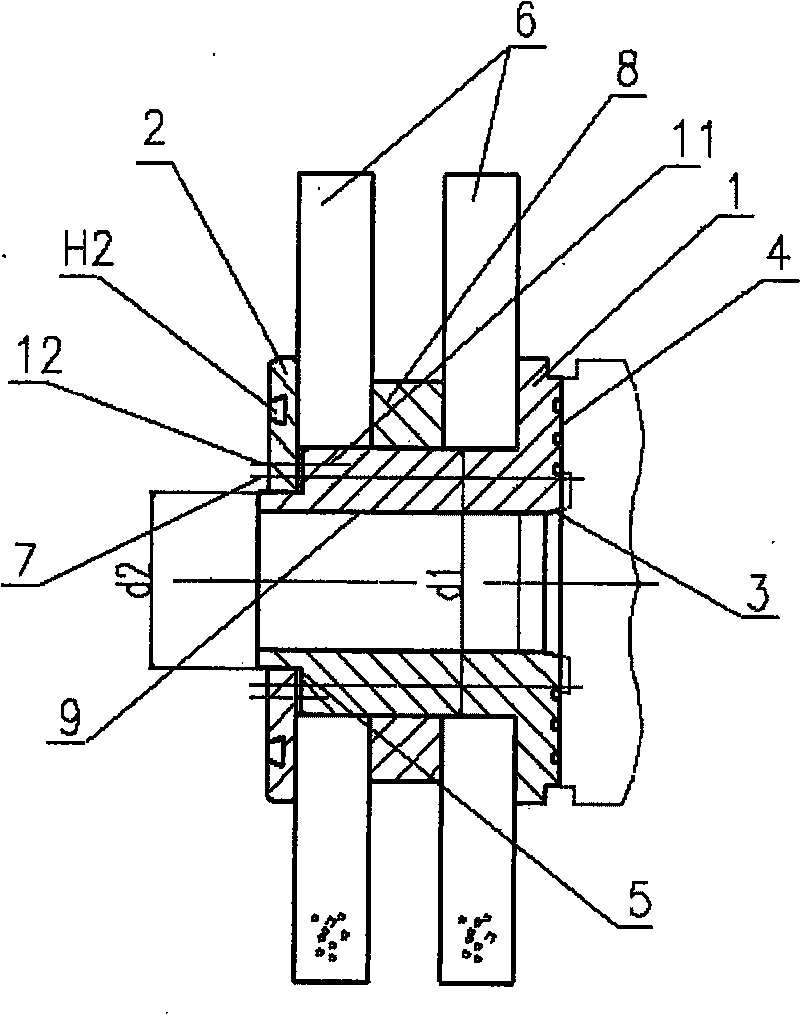

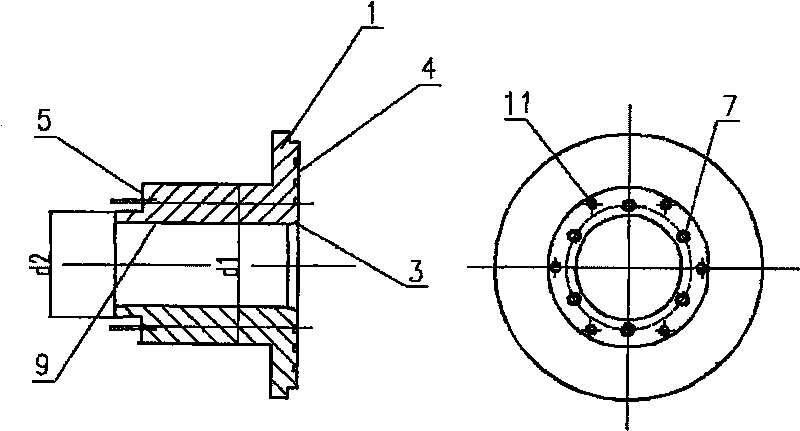

[0015] Such as figure 1 As shown, the grinding wheel chuck is combined by the chuck body 1 and the balance plate 2, and a grinding wheel 6 is housed. The width of the grinding wheel 6 is 100mm. Chuck body 1 (see image 3 Shown) have axial cylindrical inner hole 9 and joint surface 4 protruding from the end face, the inner hole is 65mm, and joint surface 4 has three concentric circular rings with uniform spacing, which is convenient to improve the machining accuracy of the end face. The joint between the joint surface and the inner hole is provided with a short micro-cone 3 that matches the grinding spindle A. The short micro-cone is 15 degrees, and the size of the big end is 70mm. This short micro-cone is positioned and installed on the grinding machine spindle. Convenient and convenient for machining. On the chuck body 1, there are 6 axial countersunk holes 7 fixedly connected with the grinding spindle A by screws and 6 screw holes 11 on the shoulder surface 5 connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com