Hot drinks machine with distribution mechanism

A technology of dispensing mechanism and hot drink machine, which is applied to household appliances, kitchen appliances, beverage preparation devices, etc., can solve the problems of danger, hot coffee scald, limited death, etc., and achieve the effect of avoiding scalding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the preferred embodiments shown in the accompanying drawings.

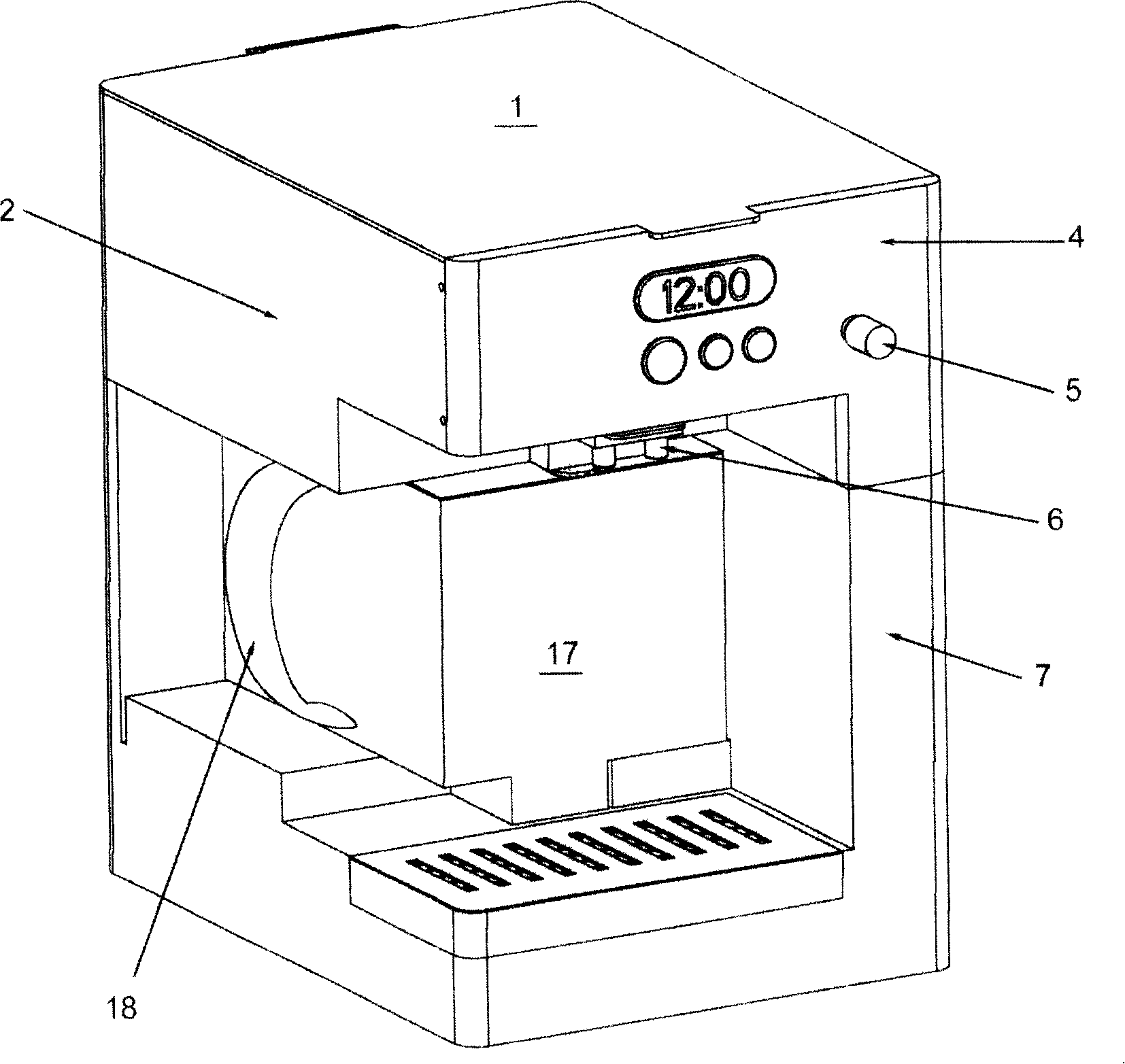

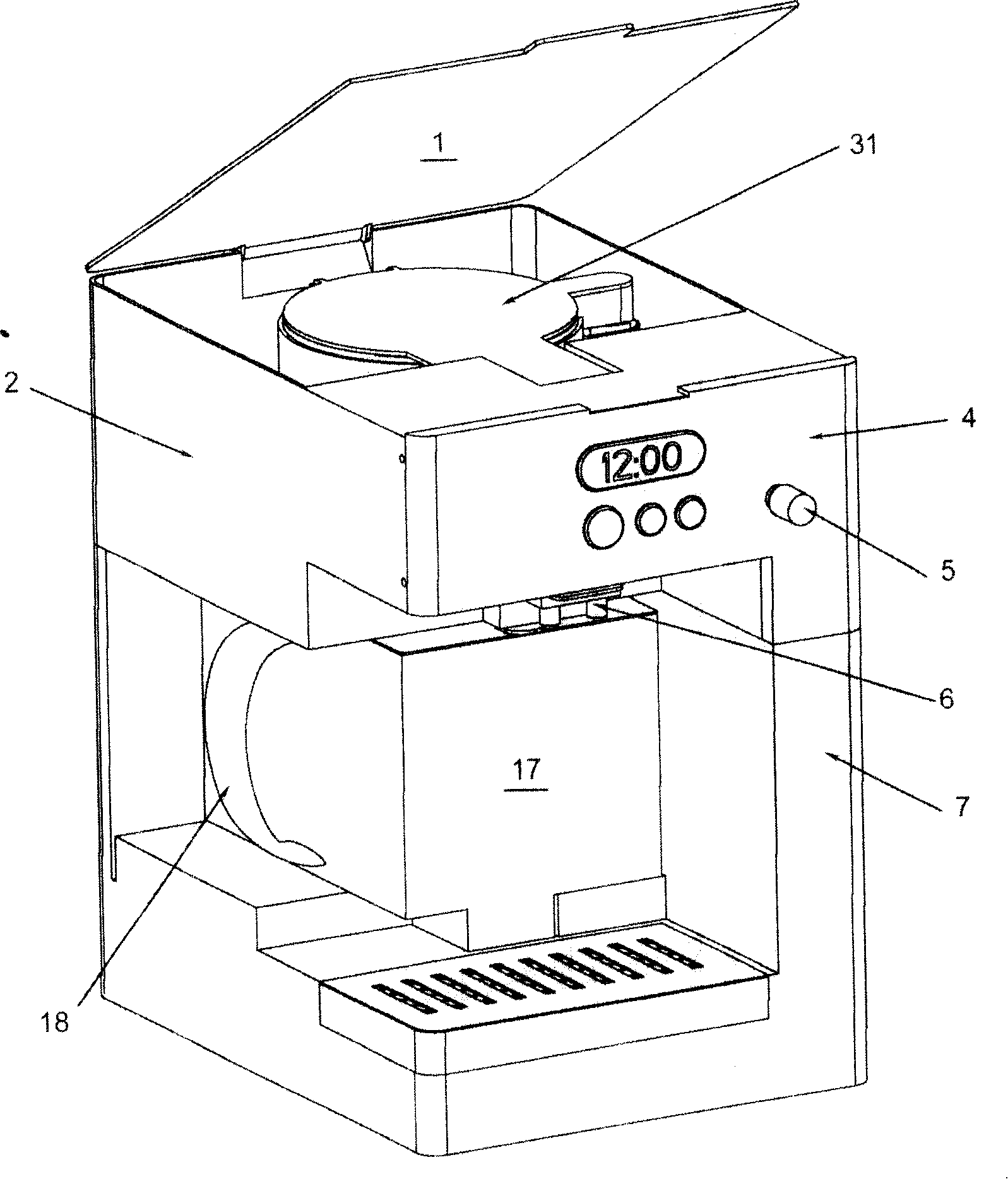

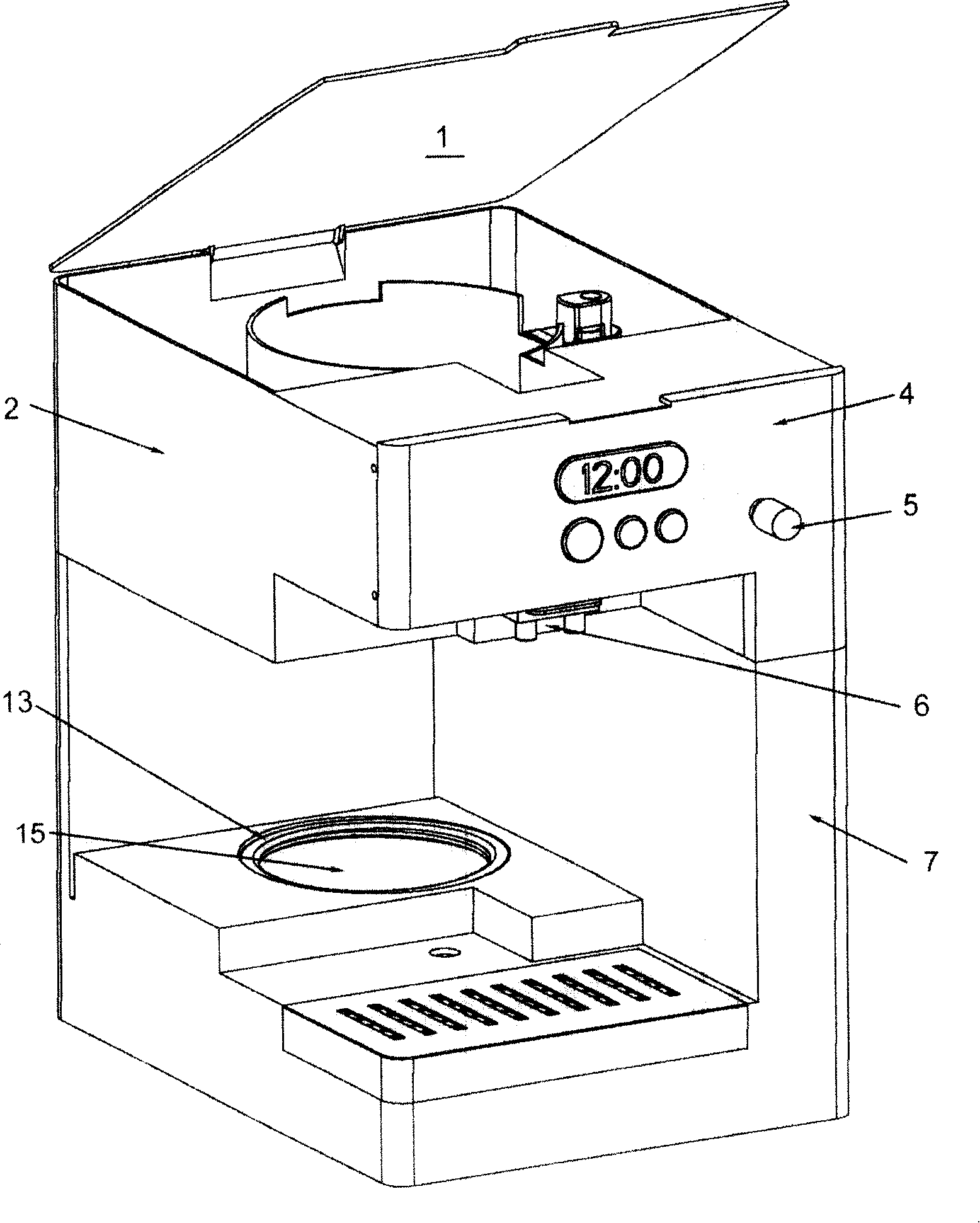

[0025] Embodiment of the hot drink machine with dispensing mechanism of the present invention, as Figure 1 to Figure 7 As shown, it includes: upper cover 1, water tank 2, printed circuit board 3, control panel 4, flow rate adjustment knob 5, nozzle 6, base 7, magnet 8, bracket 9, connecting plate 10, pumping motor 11, heating Tube 12, heat insulating ring 13, leak-proof ring 14, thermal insulation plate 15, distribution pipe 16, beverage tank 17, beverage tank handle 18, magnetic ring 19, gasket 20, pumping propeller 21, mushroom seal 22, connection Card 23, spring 24, beverage box loam cake 25, rod 26, spring 27, seal 28, filter basket 29, beverage output cavity 29a, hot water nozzle 30, nozzle cover 31.

[0026] The base 7 is the support frame of the whole hot drink machine, the water tank 2 is movably installed on the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com