Microacupunoture massager and producing method thereof

A massager and micro-needle technology, applied in kneading massage equipment, massage auxiliary supplies, medical science, etc., can solve the problems of inconvenient disinfection and cleaning, discounts in aesthetics, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

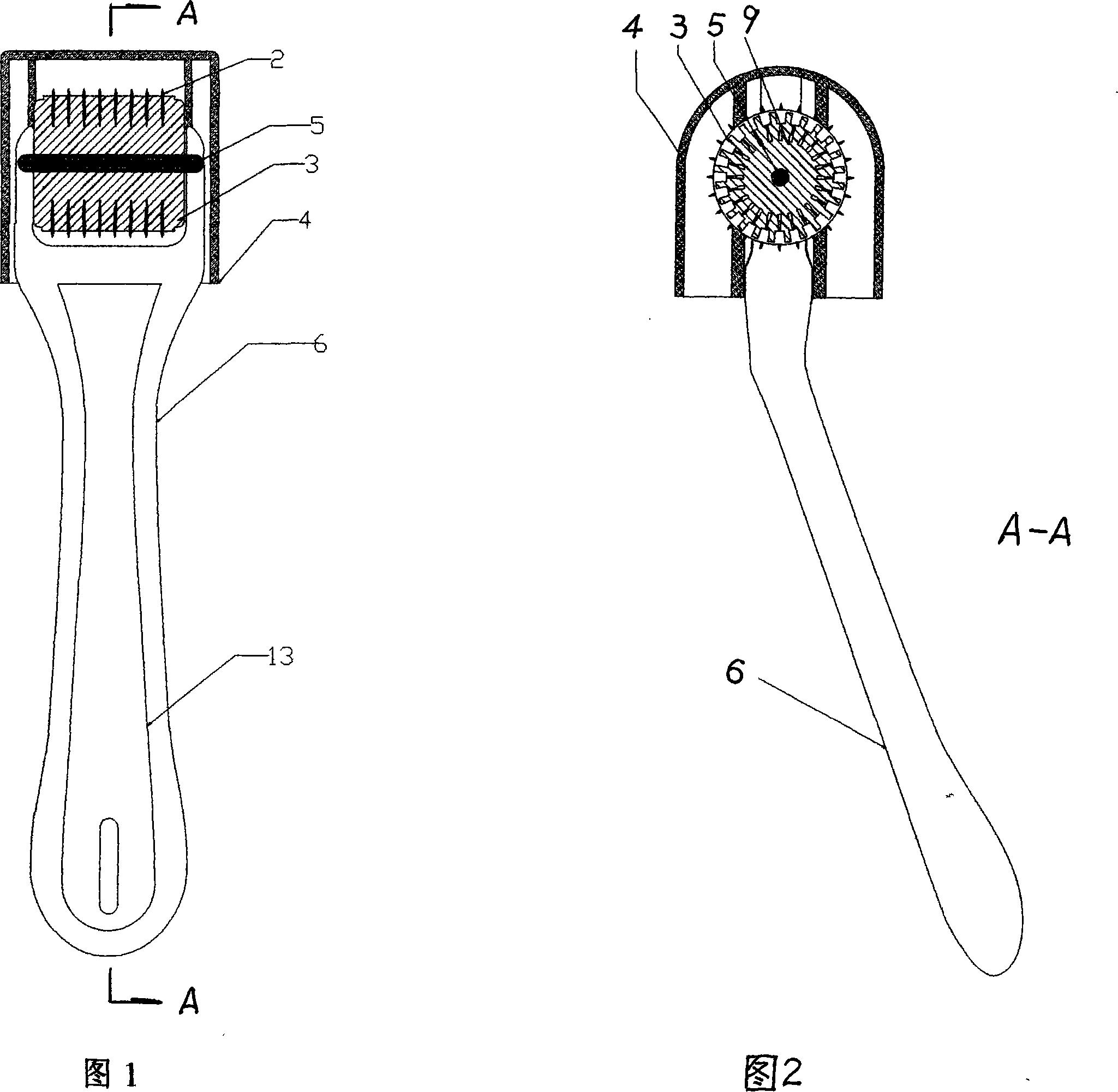

[0035] The product of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

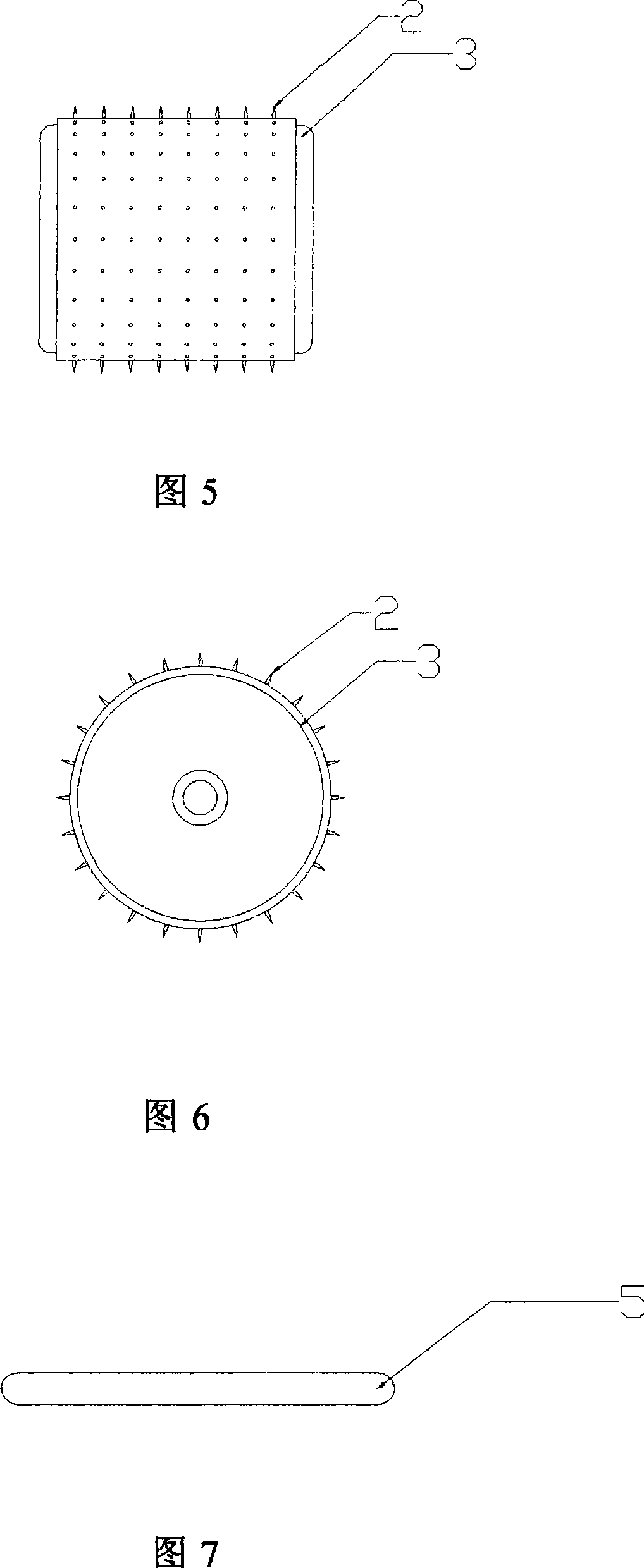

[0036] This embodiment is composed of a handle 6, a wheel shaft 5, and a pin wheel 3 arranged on the handle 6 through the wheel shaft 5. The pin wheel 3 is composed of a wheel core 9 and a needle piece 1 coated on the outer wall of the wheel core 9. The needle piece 1 is densely covered with microneedles 2.

[0037] One side of the needle sheet 1 is a plane, and grooves 7 are evenly arranged on the other side, and microneedles 2 are evenly distributed on the bosses 8 between the grooves 7 .

[0038] The needle tail 10 of the microneedle 2 is punched into a flat shape, and the needle point 11 of the microneedle 2 protrudes from the plane side of the needle piece 1 .

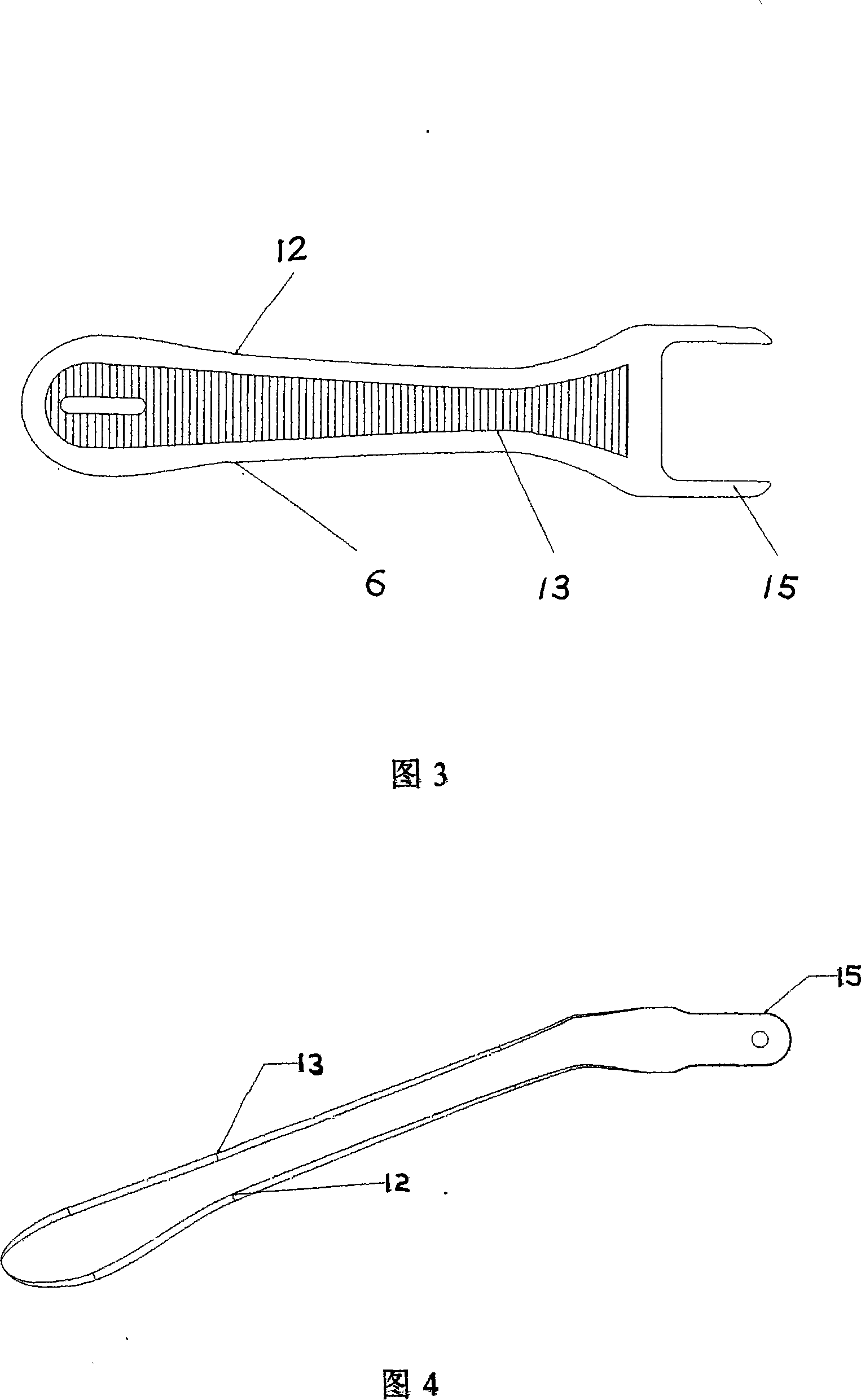

[0039] The two sides of the long handle 12 of the handle 6 are respectively embedded with thermoplastic elastomers 13 for anti-skid and decorative functions.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com