Semi-conductor electrode and method for making and solar cell containing the semiconductor electrode

A solar cell and semiconductor technology, applied in the field of dye-sensitized solar cells, can solve the problems of low photoelectric conversion rate of dye-sensitized solar cells, low utilization rate of conductive particles, low conductivity of semiconductor nanocrystal film, etc., and achieve cost reduction , prolong life, reduce the effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

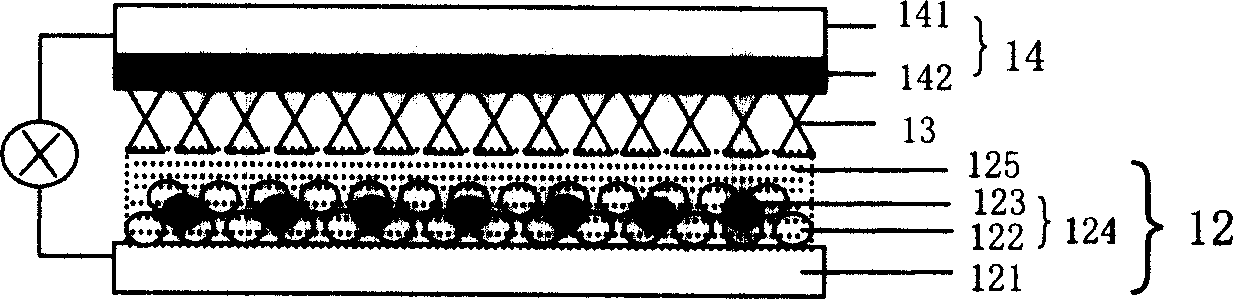

[0023] The preparation method of the semiconductor electrode provided by the present invention comprises forming a semiconductor nanocrystalline film containing semiconductor particles and conductive particles on the conductive bottom layer, and then forming a dye layer on the semiconductor nanocrystalline film, wherein the conductive particles are obtained by loading metal particles Composite conductive particles made on the surface of carbon particles.

[0024]The preparation method of the composite conductive particles includes loading metal particles on the surface of carbon particles. Metal particles can be supported on the surface of carbon particles by various existing methods, for example, impregnation reduction method or ion exchange method can be used. The preparation process of the composite conductive particles will be described in detail below by taking the impregnation reduction method as an example.

[0025] The impregnation reduction method involves contacting...

Embodiment 1

[0038] This example is used to prepare the semiconductor electrode for a dye-sensitized solar cell provided by the present invention and the dye-sensitized solar cell containing the semiconductor electrode.

[0039] (1) Preparation of composite conductive particles

[0040] 0.25 gram of carbon black powder (particle diameter is 25 nanometers) is uniformly dispersed in 100 milliliters of isopropanols, then add concentration and be 0.005 mol / L chloroplatinic acid aqueous solution, keep stirring for 5 hours, control pH value simultaneously to be 7, make carbon Black fully adsorbed chloroplatinic acid to obtain a suspension. Wherein, the consumption of the chloroplatinic acid aqueous solution is such that the weight ratio of platinum contained in the chloroplatinic acid to carbon black is 1:5. Add formaldehyde subsequently, reduce at 40 ℃ for 1 hour, the number of moles of formaldehyde is 3 times of the number of moles of platinum in chloroplatinic acid. After the reaction was c...

Embodiment 2

[0054] This example is used to prepare the semiconductor electrode for a dye-sensitized solar cell provided by the present invention and the dye-sensitized solar cell containing the semiconductor electrode.

[0055] The dye-sensitized solar cell R2 was prepared in the same manner as in Example 1, except that the composite conductive particles P1 prepared as follows were used to replace the composite conductive particles P1, and the mixed weight of the composite conductive particles P2, semiconductor particles and water The ratio is 1:200:600.

[0056] 3 grams of VXC-72 active carbon (particle diameter is 30 nanometers) is uniformly dispersed in 450 milliliters of isopropanols, then adding concentration is 0.05 mol / liter silver nitrate aqueous solution, keep stirring for 5 hours, control pH value simultaneously to be 10, make Activated carbon fully adsorbs silver nitrate to obtain a suspension. Wherein, the consumption of silver nitrate aqueous solution makes the weight ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com