Fuel supply device

A technology of fuel supply device and drive shaft, which is applied in the direction of liquid fuel feeder, charging system, liquid variable capacity machinery, etc. It can solve problems such as fire and motor heating, and achieve the effect of reducing the number of parts and realizing miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiment 1

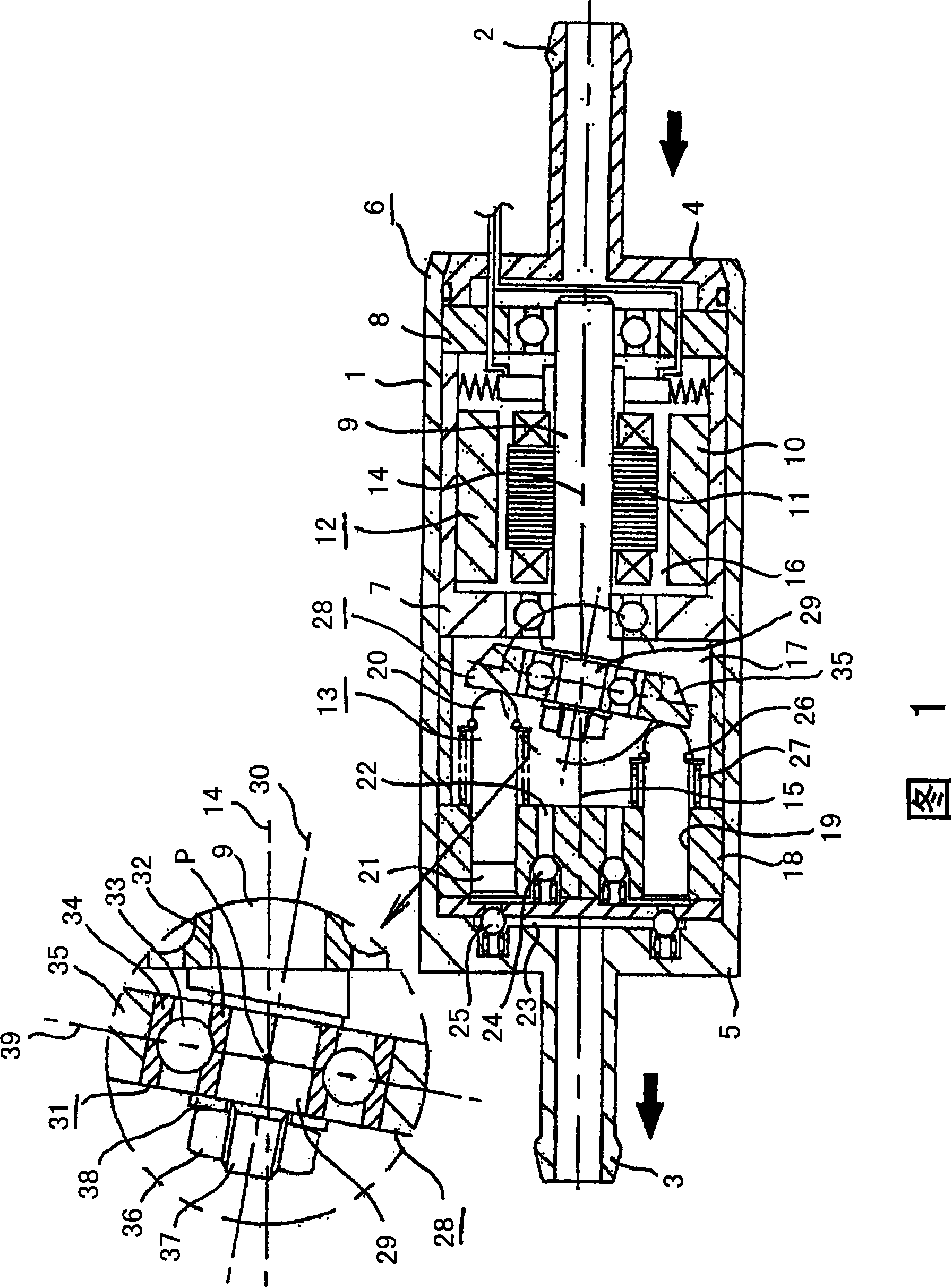

[0045] Fig. 1 is a schematic cross-sectional view showing an embodiment of the fuel supply device of the present invention, the fuel supply device shown in the figure has a hollow cylindrical shape as a whole, and has a housing 6, which includes: a cylindrical wall 1; On both ends, there are first end wall 4 and second end wall 5 with suction port 2 and output port 3 respectively. The fuel supply device also includes: the suction port 2 side in the casing 6, the drive shaft 9 supported by the bearing 7 and the bearing 8 and the motor that has the rotor 11 rotating in the stator 10, that is, the driving device 12; On the output port 3 side in the body 6 , the pump device 13 driven by the drive device 12 . The axis 14 of the drive device 12 coincides with the axis 15 of the pump device 13 .

[0046] The fuel that enters the casing 6 from the suction port 2 flows axially generally in the drive device chamber 16 in the casing 6 in which the drive device 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com